Method relates diesel cetane, octane ratings

A method tested on various diesel blends of known cetane numbers showed a good correlation with the fuel’s octane numbers.

Spontaneous ignition results in knock in a spark-ignition engine, whereas spontaneous ignition is required in a diesel engine. In effect, octane number and cetane numbers are opposite measurements of the same phenomenon. Low octane number implies high cetane number.

It is advantageous to test diesel fuels in octane test engines that are much more widely available than cetane test engines. To investigate this possibility, we tested 50-50 blends of diesel fuels with iso-octane in a motor octane engine under standard operating conditions. The motor octane test is run at a high temperature, which should favor operability with diesel fuel blends.

Correlations

We carried out the tests with six diesel fuels of known cetane number, resulting in a good correlation. The correlation, however, did not work well for blends containing a cetane improver. Motor octane test results underpredicted the effect of cetane improver on ASTM D613 cetane engine results.

The correlation for diesel fuels without cetane improvers using the motor octane blending value is:

Cetane number = 58.4 0.54 × Motor octane blending value.

Subsequently, we performed a more detailed study including diesel fuels from seven different refineries within six different companies. Diesel reference fuels were included, and the diesel fuel from one refinery was tested with 0.1% and 0.2% cetane improver.

Table 1 shows the results.

As in the preliminary study, the effect of cetane improver on cetane number was underpredicted.

The correlation based on fuels without cetane improver using the motor octane for a 50-50 blend of diesel and iso-octane is:

Cetane number = 105.9 0.94 × Motor octane for 50-50 blend.

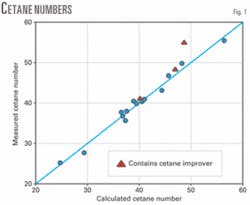

Fig. 1 shows the close agreement between calculated and measured cetane number for diesel fuels without a cetane improver.

The standard error, which is only 1.29 cetane numbers, can be explained by the variability of the cetane and motor octane tests. The lack of fit must be small.

Converting the above equation to the blending value form yields the improved equation:

Cetane number = 58.9 0.47 × Motor octane blending value.

The improved equation is similar to that obtained in the preliminary work, but this equation gives predictions about three cetane numbers higher. The industry may wish to consider this test procedure as an alternate to cetane engine test, ignition delay tests, and the cetane index.

Use of the correlation

The blending-value form of the equation is useful because it facilitates evaluation of alternate constituents of diesel fuel.

For example, consider balancing the use of 325°+ F. reformer feed vs. its use to maximize reformate value. This might be done by taking the cut after hydrotreating as a premium component for low-sulfur diesel. Otherwise, the cut point before hydrotreating could be changed to include the 325°+ F. portion in diesel fuel.

In either case, one can estimate the cetane number by assuming that the motor octane blending value will be reasonably close to the motor octane rating of the cut. Based on gas chromatograph data for a reformer feed, the motor octane of the 325°+ F. portion will be about 45. On that basis, the cetane number will be about 38, quite suitable for diesel fuel:

Cetane number = 58.9 0.47 (45) = 37.7

Balanced against the increase in diesel fuel volume would be the loss of reformate quantity and quality. When reforming to a 92 (R + M)/2 full boiling reformate, the 325°+ F. reformate cut will be about 100 (R + M)/2.1 Despite this large disadvantage, such a change could be worthwhile under unusual marketing and refining conditions.

Further development

The under-prediction of cetane improver effects could be due to the high surface temperature of the mixture heater with this method. Intake air temperature was 100° F. and the air-fuel mixture is 300° F.

A preliminary test with the mixture heater turned down or off might provide an answer. The fuels would be 50-50 iso-octane blends of high-cetane reference fuel, low-cetane reference fuel, and low-cetane reference fuel with 0.2% cetane improver added.

If the results of preliminary tests are promising, it might be feasible to increase the intake air temperature so that a 300° F. mixture temperature could be achieved with a lower temperature mixture heater.

Acknowledgment

The data reported here were obtained at the DuPont Co. Petroleum Laboratory under the supervision of W.S. Vilda.

Reference

- www.gasolineblendingplus.com

The author

William E. Morris is a consultant, Wilmington, Del. He provides gasoline blending computer programs via his web site, www.gasolineblendingplus.com. Morris worked for ExxonMobil Corp.’s Bayway, NJ, refinery for 7 years. Then he joined the DuPont Co. petroleum laboratory where he provided technical service for refineries in support of petroleum chemical sales. Morris holds a BS in chemical engineering from the University of Missouri.