US REGULATIONS-Conclusion US pipeline industry preparing for regulatory changes

Kofi S. Inkabi

Exponent

Oakland, Calif.

Elizabeth K. Reilly

Exponent

Menlo Park, Calif.

Significant regulatory changes are coming to the pipeline industry. Its members are responding to the Pipeline and Hazardous Materials Safety Administration (PHMSA) regarding proposed regulatory changes to 49 Code of Federal Regulations (CFR) Part 192 through comments and via industry groups, such as the Interstate Natural Gas Association of America and the American Gas Association. PHMSA will in due course respond to the industry's questions and concerns and make its final ruling.

This article continues examination of the proposed changes to 49 CFR Part 192.

Corrosion control, evaluation

The annual cost associated with corrosion damage in the US of structural components is greater than the combined annual cost associated with natural disasters, including hurricanes, storms, floods, fires, and earthquakes.1 Typical corrosion mechanisms include uniform corrosion, stress corrosion cracking, and pitting corrosion. The corrosion control measures in the current CFR are in the form of requirements regarding coatings, cathodic protection systems, and integrity assessments.

Implementing the new rules will require wide-ranging changes to the application of corrosion control measures, involving considerable assessment work. The sections most heavily affected are §192.319, 192.461, 192.465, 192.473, 192.478, 192.485, 192.493, Subpart O, and Appendix D.

Changes will involve additional requirements for assessing coating damage (§192.461), including immediately following new installation (§192.319). Operators will have to assess the integrity of the coating using DC voltage gradient or AC voltage gradient before backfill. A maximum timeframe for remediation of cathodic protection deficiencies and transmission will be established, and interrupted close interval surveys required, to determine the extent of the area with inadequate CP and confirm restoration (§192.465).

On transmission lines (it is still unclear if these rules apply to gathering lines) operators also will have to perform interference surveys on a periodic basis to detect electrical stray current (from both AC and DC interference), analyze results, and mitigate detrimental effects within 6 months of the survey (§192.473). The regulations do not clearly define either the frequency with which surveys will need to occur or whether all transmission pipe will have to be surveyed for interference.

Operators will further need to implement an internal corrosion program (twice each calendar year) to monitor and mitigate corrosive constituents in gas being transported (§192.478). Clarification is needed regarding where the gas stream and liquid quality should be monitored.

The bulk of the proposed changes will affect internal corrosion direct assessment (ICDA) and stress corrosion cracking direct assessment (SCCDA) programs. Under the new regulations, these programs would be defined by NACE SP0206-2006 and NACE SP0204-2008 for ICDA and SCCDA, respectively.

ICDA

The new rules will impose the following limitations on indirect inspection of internal corrosion: "[T]he operator must use pipeline specific data, exclusively. The use of assumed pipeline or operational data is prohibited." Here again, the operator will be required to consider the accuracy, reliability, and uncertainty of data, including but not limited to "gas flow velocity (including during upset conditions), pipeline elevation profile survey data (including specific profile at features with inclinations such as road crossing, river crossings, drains, valves, drips, etc.), topographical data, depth of cover, etc. The operator must select locations for direct examination, and establish the extent of pipe exposure needed (i.e., the size of the bell hole), to explicitly account for these uncertainties and their cumulative effect on the precise location of predicted liquid dropout." The changes in the direct assessment portion are highly prescriptive when internal corrosion is found, requiring additional excavations at specific feature sites.

SCCDA

Most of §192.929 is redefined or added, meaning extensive changes to operators' SCCDA programs. The NACE SP0204-2008 standard provides the framework for this methodology, but the following factors must be analyzed as part of evaluation:

• Effects of a carbonate-bicarbonate environment, including the implications of any factors that promote the production of a carbonate-bicarbonate environment (such as soil temperature, moisture, the presence or generation of carbon dioxide, and CP.

• Effects of cyclic loading conditions on the susceptibility and propagation of SCC in both high-pH and near-neutral-pH environments.

• The effects of variations in applied CP (such as overprotection, CP loss for extended periods, and high negative potentials).

• The effects of coatings that shield CP when disbonded from the pipe.

• Other factors affecting the mechanistic properties associated with SCC, including historical and current operating pressures, high-tensile residual stresses, flowing product temperatures, and the presence of sulfides.

The SCCDA plan must also include at least two above-ground surveys and a minimum of three direct examinations within the SCC segment. If SCC is detected the operator will be required to undertake extensive remediation and mitigation. The operator could elect to remove or sleeve the affected pipe, grind out the affected area, or perform a hydrotest according to the procedure specified in the new code. Any reduction in WT will have to be validated by ASME/ANSI B31G or RSTRENG, with remaining thickness sufficient to meet the design requirements of Subpart C. Post-assessment steps, in addition to the NACE requirements, must include a reassessment plan at an interval compliant to §192.939 and must consider:

• Evaluation of discovered crack clusters during the direct examination step in accordance with NACE RP0204-2008 Sections 5.3.5.7, 5.4, and 5.5.

• Conditions conducive to creating the carbonate-bicarbonate environment.

• Conditions in the application (or loss) of CP that can create or exacerbate SCC.

• Operating temperature and pressure conditions, including operating stress levels on the pipe.

• Cyclic loading conditions.

• Mechanistic conditions influencing crack initiation and growth rates.

• Effects of interacting crack clusters.

• Sulfides.

• Disbonded coatings shielding CP from the pipe.

Implementing the SCCDA as written would entail considerable information, investigation, and follow-up actions.

Change management

Subpart O of 49 CFR 192 specifies the elements that a gas pipeline integrity management program must contain. Subparagraph (k) is being revised to specify that one of the required elements be "a management of change process as required by §192.13(d)." Section 192.13(d) is a proposed new section in Subpart A (General) requiring:

"Each operator of an onshore gas transmission pipeline must evaluate and mitigate, as necessary, risks to the public and environment as an integral part of managing pipeline design, construction, operation, maintenance, and integrity, including management of change. Each operator of an onshore gas transmission pipeline must develop and follow a management of change process, as outlined in ASME/ANSI B31.8S, Section 11, that addresses technical, design, physical, environmental, procedural, operational, maintenance, and organizational changes to the pipeline or processes, whether permanent or temporary."

The proposed §192.13(d) lists the elements that must be included in the management-of-change process. These elements are taken directly from ASME/ANSI B31.8S, Section 11, Subparagraph (a):

• Reason for change.

• Authority for approving changes.

• Analysis of implications.

• Acquisition of required work permits.

• Documentation.

• Communication of change to affected parties.

• Time limitations.

• Qualification of staff.

ASME/ANSI B31.8S, Section 11, Subparagraphs (b)-(h) provide further explanation and examples of these required elements.

The following industry publications provide additional guidance on management of change processes. They are not referenced by 49 CFR 192 and therefore are not needed to demonstrate compliance.

• API RP 1173, Pipeline Safety Management System Requirements.

• RC14001, Responsible Care Management System and Certification.

• PRCI IM-2-1, Facility Integrity Management Program Guidelines.

• Canadian Energy Pipeline Association, Facility Integrity Management Program Recommended Practice.

Recordkeeping clarification, expansion

Records management activities should be performed in compliance with all requirements arising from current business needs, the regulatory environment, and community expectations. The notice of proposed rulemaking (NPRM) proposes to modify §192.13(e) to require each operator to make and retain reliable, traceable, verifiable, and complete records that demonstrate compliance with 49 CFR Part 192 in accordance with Appendix A, Records Retention Schedule for Transmission Pipelines.

The Pipeline and Hazardous Materials Safety Administration (PHMSA) states: "Section 23 of the [2011 Pipeline Safety] Act requires the Secretary of Transportation to require verification of records used to establish maximum allowable operating pressure (MAOP) to ensure they accurately reflect the physical and operational characteristics of certain pipelines and to confirm the established MAOP of the pipelines. PHMSA has determined that an important aspect of compliance with this requirement is to assure that records that demonstrate compliance with Part 192 are complete and accurate. The proposed rule would add a new paragraph (e) that clearly articulates the requirements for records preparation and retention and requires that records be reliable, traceable, verifiable, and complete."2

PHMSA has not clearly defined what constitutes a reliable, traceable, verifiable, and complete record in the context of 49 CFR Part 192 as a whole. Generally, a reliable record is one in which the contents can be trusted as a full and accurate representation of the transactions, activities, or facts and can be depended on in the course of subsequent transactions or activities.3 In the context of establishing MAOP, the National Transportation Safety Board (NTSB) and PHMSA have indicated before that reliable records are those that are traceable, verifiable, and complete.4 5

PHMSA defines these terms within this context as follows:

• Traceable records are those which can be clearly linked to original information about a pipeline segment or facility.

• Verifiable records are those in which information is confirmed by other complementary, but separate, documentation.

• Complete records are those in which the record is finalized as evidenced by a signature, date, or other appropriate marking.

It is unclear whether PHMSA intends to apply these definitions to Part 192 in its entirety or will issue revised definitions specific to the application section. It is also not clear whether PHMSA will issue formal criteria for demonstrating the reliability of one's records in accurately capturing the information intended.

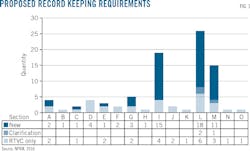

Although §192.13(e) would add a significant number of new recordkeeping requirements throughout 49 CFR, the vast majority are compliance oriented in that they relate to documenting and retaining information for activities that operators must already perform under the existing rules. Most of these requirements apply to Subparts I (Corrosion Control), L (Operations), and M (Maintenance), as shown in Fig. 1.

Given the many changes proposed and the increased emphasis and scrutiny on recordkeeping, operators may want to perform a regulatory gap analysis to identify how these changes will affect existing operations. When properly maintained and structured, tools such as requirement matrixes can provide operators the means to quickly and efficiently identify impacted guidance documents when industry regulations are revised or reissued.

Operators may also want to consider performing a baseline audit of their existing records to assess the adequacy of their engineering records management program, including the quality assurance and control processes in place to ensure that any records compliance issues are readily detected and corrected. It is not uncommon for inadequate training and procedures to compromise the reliability of both hard copy and electronic records.

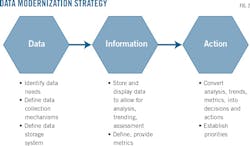

For some operators, these changes may present an opportunity to move toward a business model in which compliance records can be readily leveraged to enhance asset management programs. A key to effective asset management is the ability to transform data into well-informed actions (Fig. 2). Operators who make this transition will be able to make decisions and rate-case justification statements based on facts. They will also have a foundation for near real-time system performance monitoring, quantitative risk assessments, fitness-for-service evaluations, reliability-centered maintenance, and resource allocation optimization.

References

1. US Department of Transportation, Federal Highway Administration, "Corrosion Costs and Preventive Strategies in the United States," Publication FWHA-RD-01-156, 2002.

2. NPRM, Federal Register, Vol. 81, No. 68, Apr. 8, 2016, p. 20807.

3. ISO 15489-1, "Information and documentation -- Records management -- Part 1: General," Sept. 15, 2001.

4. NTSB, Safety Recommendation P-10-1, Appendix B, Jan. 3, 2011, p. 2.

5. PHMSA Advisory Bulletin 2012-68, Federal Register Vol. 77, No. 88, May 7, 2012, p. 26823.