Offshore Petroleum Operations Deepwater pipelay prospects prompt study of mechanical connectors

Warren R. True

Pipeline/Gas Processing Editor

A joint industry project to study mechanical connectors for pipeline construction will issue results to its participants next month.

Although the study addresses mechanical connectors' use in any environment, connectors are being looked at by offshore operators as a means to minimize pipeline-installation costs, especially in deepwater.

The joint industry project, dubbed "Low Cost Pipeline Connection Systems," does not compare available connectors but was initiated to specify criteria that operators can use to qualify connectors for use.

The project was organized and is now being managed by Hunting Oilfield Services, Aberdeen.

Secondarily, the project aims for the following:

- To develop a clear design premise.

- To address relevant installation and service issues such as corrosion protection, installation methods, and repair methods, and costing models.

- To develop specifications and acceptance criteria for the testing of pipeline connectors. This will parallel the ISO specifications and API recommended practices for the testing of downhole connectors.

- To prove the adequacy of the specifications and criteria by analytical validation methods and in particular by testing programs that simulate, with adequate margins of safety, the installation and service loads on pipeline connectors.

- To establish and prove, as far as possible, a standardized approach to the testing of pipeline connector systems.

The project began in October 1994. Participants in the study are Amoco Corp., British Gas, BP, Conoco U.K., Enterprise Oil, Exxon Production Research, Maersk, Petrobras, Shell, Stat oil, Texaco Britain, Andrew Palmer & Associates, BJ Tubular Services, Coflexip Stena Offshore, the U.K. Health & Safety Executive, Hunting Oilfield Services, Itochu, Saipem U.K., and Subsea Offshore, U.K.

That the study is being carried out at all indicates the growth in nonwelded approaches to pipeline construction and reflects industry's efforts to hold down construction costs, especially for offshore. Yearly, labor costs exceed 45% of pipeline construction costs, as reported in Oil & Gas Journal's annual Pipeline Economics Reports (latest: OGJ, Nov. 27, 1995, p. 39).

Early use

Mechanical connectors are precisely that: They use the mechanics of physical resistance rather than material bonding to effect a connection between ends of two pieces of pipe.

Welding, by contrast, employs heat and the adherence of a third element-the electrode-to bond steel to steel. Depending upon pipe size, metallurgy, and locale (offshore; remote land sites), welding can be labor intensive and therefore very expensive.

Early connectors were used for construction and some current repair methods involving connectors continue to use welding. But the surge in mechanical connector use in recent years has seen the form of threaded configuration as predominant.

An exception is Jetair Inc.'s Positive Sealing coupling, discussed presently, which employs mechanical bonding rather than welding or screwing.

Hunting Oilfield Services, which also supplies mechanical connectors, has reported that mechanical connectors were used by the oil industry for constructing pipelines until the mid 20th Century when welding evolved as a more reliable technique.1

Early mechanical connectors relied on trapping lubricant to create a pressure seal.2 These early connectors are unsuitable for modern pipelines.

Connectors continued to be used downhole because of their make-up speed and to satisfy the need for reversibility. Advances in downhole connection technology have led to safer, more reliable connectors for pipelines.

These advances have included design improvements such as metal-to-metal seals; developments in lubricants, sealants, and antigalling coatings; finite element analysis/design; combined load testing; computer-numerical-control manufacture; electronic gauging; and computerized torque-turn monitoring.

Laying options

A reliable mechanical pipeline connector exhibits all the following:1

- Metal-to-metal seals for long-term pressure integrity

- Capacity to withstand all installation and service loads

- Smoothly contoured and slimline external profile

- Constant bore

- External seal against seawater

- Quick make-up

- Adaptability for internal liners and coatings.

It is the potential for considerable savings that attracts operators to mechanical connectors. These savings stem from faster make-up than a welded connection and connectors' ability to be laid from a variety of vessels, including lower cost service vessels as well as drilling rigs, thus reducing lay contractor costs.

One end of a line pipe segment shows lugs and threads machined for Hydril Co.'s Series 2000 mechanical pipe connector. This one awaits make up and installation last year in the Gulf of Mexico (Fig. 3).

Hydril Co., Houston, a supplier of one type of connector, has analyzed the cost savings in three areas: use of nonweldable materials (Table 1 [84328 bytes]), rig or barge mobilization costs (Table 2 [14677 bytes]), and joint cycle time for a J-lay operation (Table 3 [16198 bytes]).

For the proposed Oman-to-India pipeline, Hydril compared costs for a J-lay operation that would use welding vs. its Series 2000 pipeline connector.3 Results, shown in Table 4 [26084 bytes], suggest an overall savings of nearly $78 million on installation with use of a connector. Bulk of the savings comes from reduced laying time: 607 days for welding vs. 161 for connectors.

Hunting has also compared welding vs. connector make-up on large vessels.

Typical lay rates on large layships using highly automated welding processes, says Hunting, are around 4 km/day. Similar lay rates are achieved by reelships.

For offshore J-lay of 12-m single joints, the assembly rate is comparable, about 3.5 km/day, but a further increase in speed is possible by use of double, tripled, or even quadrupled joints, preassembled or welded at the quayside.1

On the horizontal, the assembly rate is faster, up to 20 joints/hr, because pipe handling becomes easier and because such operations as removing protectors and inspecting and lubricating threads can be performed in parallel with assembly.

This results in lay rates of more than 5.5 km/day.

Use of more than one assembly station on horizontal, resulting in a higher lay rate, may also be possible. Connectors can therefore at least double the lay rate of conventional pipelay vessels.

The assembly rate is independent of pipe diameter, wall thickness, and material. Connectors are therefore particularly suited to assembly of large diameter, heavy-wall pipe, and difficult-to-weld materials such as duplex and clad pipe.1

But the size of modern large lay barges makes them expensive: they often can accommodate up to six welding stations, handling double joints, plus stations for nondestructive testing (NDT), field jointing, and anode attachment.

On the other hand, reelships are fast during laying but expensive in day rate, site fabrication, and mobilization and demobilization, and they are limited in how much pipe they can carry on a reel. Offshore replenishment of pipe is impossible.

Reelships hold a particular niche in the laying of duplex pipe which can be welded onshore and laid rapidly.

Use of connectors, by comparison, allows similar lay rates with a single station and without the need for nondestructive testing (NDT). Pipelay, says Hunting, can therefore take place from a variety of vessels with low day rates-diving service vessel, marine service vessel, drill rig, or jack up.

In deepwater, pipelaying can be accomplished with the existing derrick and pipehandling equipment on drill rigs. Alternatively, a modular assembly station can be fitted on the side of the drilling rig so that pipelay can proceed concurrently with drilling.

An angled J-lay tower can also be used to install pipelines in shallow water.

Typical day rates in the Gulf of Mexico for less specialized vessels are $60,000, which compares with day rates of $150,000 for dedicated pipelay vessels such as lay barges and reelships.1

The versatility eliminates the need to mobilize a dedicated pipelay vessel with its attendant high mobilization and demobilization costs.

This advantage is particularly strong for short infield flow lines where mobilization and demobilization costs comprise much of the total cost and also in such regions as West Africa where few pipelay vessels are available.

The sealing ring, third element in Hydril Co.'s Series 2000 mechanical pipe connector, is set in place (Fig. 4).

Material choices

When the medium to be transported is too corrosive for carbon steel, the next weldable alternative is duplex. Mechanical connectors allow use of unweldable or difficult-to-weld, corrosion-resistant materials such as 13% chrome, internal glass reinforced plastic (GRP) and polyethylene (PE) liners, and epoxy coatings.

In projects needing corrosion-resistant pipe, material costs make up a large proportion of the total cost. Cost savings when mechanical connectors are used rather than welding can be 70-80% for material.

Use of mechanical connectors also allows the operator to take advantage of technical aspects of liners: compared to high chrome steels, GRP-lined pipe resists corrosion bettter, exhibits no crevice corrosion, and has better mechanical properties at high temperatures.

Fiber-reinforced plastic (FRP) liners will operate at temperatures as high as 370o F.4

Polyethylene liners have maximum operating temperatures of as low as 190o F. for water service and 140o F. for hydrocarbon service.

Hunting says that mechanical connectors provide an alternative to the difficulty of welding high-strength steels in the field. Such steels require post-weld heat treatment to achieve acceptable levels of ductility and fracture toughness in the weld and heat affected zone.1

Threaded connectors remove the need to weld. Or, when weld-on connectors are desired, as for large-diameter pipe, the welds can be carried out, heat treated, and inspected off-line in the factory, rather than the field.

Overall, the benefits of connectors must be balanced against their cost, any project-specific testing which may be required, and any needed adaptation to a vessel, fitting, for example, a stinger and tensioner to allow an MSV to S-lay pipe.

The magnitude of any savings depends on several factors, the main ones in most cases being use of a low-cost alternative to duplex and avoidance of the mobilization costs and the day rate of a dedicated pipelay vessel.

Variations

The most common types of connector employ threads for makeup, but other types are suitable for pipelines.

The joint industry project whose main report is due June has studied four types (Fig. 1 [89070 bytes]): premium threaded connectors (7 in.; 13% chrome), as in Hunting's Seal-Lock Apex; snap-together (16 in.; X-60 carbon steel), as in Hunting's Merlin connector; push-fit connectors (6 in.; X-52 carbon steel with PE liners), as in Jetair International Inc.'s Positive Sealing coupling; and snap-ring connectors (4 in.; X-52 carbon steel), such as Hunting's Posi-Conn.

Internal dimensions are checked on Jetair's Positive Sealing coupling mechanical connector (Fig. 5).

An anode is secured on a 4-in. pipeline about to be laid piggybacked in the Gulf of Mexico with Jetair's Positive Sealing coupling connector (right) used for joining the strings (Fig. 6).

Threaded connectors

Premium threaded connectors (Fig. 1a [89070 bytes]) have metal-to-metal seals and, for sealing, do not rely on dope entrapment. They have helical threads and are assembled with computer controlled torque-turn equipment. Examples are Hunting's Fox and Seal Lock Apex.

The helical thread, however, provides a potential leak path. Also, the connector can unscrew under torsional loading.1

Hydril Co. has developed a connector specifically for pipeline installation (Fig. 2 [84328 bytes]). It consists of three elements:

- Right-hand/left-hand opposed threads cut onto the outside wall of the pipe ends along with notches or "lugs" cut into the pipe ends (Fig. 3)

- An internally threaded coupling into which the pipe ends are drawn

- A metal seal ring that fits inside the pipe ends and effects the metal-to-metal seal of the connection (Fig. 4).

The connector can join pipe made of high strength/nonweldable materials. The connector's coupling may serve as a pipeline buckle arrestor, if needed.

The lugs, when interlocked with a joining segment of pipe, prevent backoff from torsional loads. Such torque may be a byproduct of installation or result from thermal expansion or upheaval buckling.

To ensure proper fit, these lugs are cut so that they can be aligned and fit in only one orientation. The joining pipes' exteriors are marked to guide proper makeup.

The threads are right-hand/left-hand opposed so that, as the coupling is turned, it draws the pipe ends together to engage the lugs and thereby energizing the metal-to-metal seal ring.

The male threads can be cut directly on seamless or seam welded pipe. Any pipe material specifications can be accommodated.

According to Hydril, a three-step procedure ensures tight makeup:

- Thread protectors remain in place until the joint is positioned for makeup, and lubricant is applied evenly to the threads.

- A joint-analyzed torque makeup system ensures that the correct amount of torque has been transferred to preload the connection. This system provides a joint-by-joint permanent record of the torquing characteristics of each joint.

- A fast, accurate helium leak-check system ensures that no leak across the seal is present.

Hydril's connector was put in service in July 1995 in the Gulf of Mexico on export risers on a floating production facility for Enserch's Garden Banks Block 388 development.

Deployed in 2,190 ft of water, the oil export riser is 123/4-in. OD and the gas export riser 85/8-in. OD. Each riser took 48 connections.

Hydril says other riser applications are being planned.

Snap-together connectors

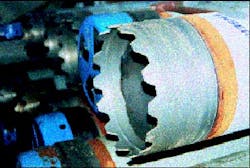

Using parallel interlocking teeth rather than a helical threadform, snap-together connectors (Fig. 1b [89070 bytes]) are pushed together with an hydraulic clamp. The design of the teeth prevents them from interlocking other than when fully madeup.

These connectors have multiple metal-to-metal seals and can be reversed by injecting hydraulic fluid into the annulus to separate the teeth.

Hunting's Merlin, for example, has been used on casing, conductor pipe, J-tubes, and tension-leg platform tethers, as well as on the BP Harding pipeline (OGJ, Aug. 28, 1995, p. 47).

For the Harding installation, pin and box components of Merlin were welded onto 12.5-m joints which were then assembled into 75-m strings. The strings were then loaded onto a marine support vessel (MSV), transported to the installation site, and there lowered to the seabed.

The strings were connected on the seabed with a 30-ton vehicle designed by SubSea Offshore that aligns the ends of the pipe before stabbing and carries the makeup clamp for pushing the connectors together.

Push-fit connectors

Interference fit between a tapered coupling and the pipe is the principle behind push-fit connectors. The pipe is not machined (Fig. 1c [89070 bytes]).

During makeup, the teeth in the coupling deform and create multiple metal-to-metal seals. Epoxy is used as a lubricant and assists the sealing and strength of the connector.

The Positive Seal Coupling from Jetair International Inc., Houston, has been used on land and offshore for joining 2 to 12-in. OD pipe (OGJ, Sept. 26, 1994, p. 100).

The coupling (Fig. 5), developed in 1979 and first patented in 1982, was originally for use with internally coated pipe, eliminating as it does the need for internal girth weld coating repair. The coupling is also suitable for bare pipe.

Pipe wall-thickness schedules of up to 160 and API 5L Grades through X-80 can be accommodated, says Jetair. The positive seal connection requires no X-ray and thereby reduces construction time.

Minimal pipe-end preparation is required. And there is no ID size restriction to product flow or pigging operations, no loss of pipe length during make up, and no stress fatigue or cracking of pipe ends.

Jetair says that the coupling connection has 100% pressure, stress, and load capability under ANSI/ASME Piping Codes B31.3, B31.4, B31.8, and under CAN/CSA-Z183, Z184 and complies with the requirements of U.S. Department of Transportation 49 CFR Parts 192 and 195.

The patented coupling uses a press-on mechanical metal-to-metal interference fit and features a coupling with finely machined internal serrations. The tapered interference fit of the coupling ID is machined smaller than the OD of the line pipe it is designed to join.

The controlled interference fit, in conjunction with the serrations on the ID surface of the coupling, says Jetair, produces a connection that exceeds the minimum yield specifications of the pipe itself.

The offshore version of this connection is somewhat longer and displays its tapered interference fit slightly different from the onshore version.

The rates of taper for the onshore and offshore versions are the same. The additional length in the offshore version, however, results in an increased interference fit overall, says Jetair.

This taper variation, says the company, increases the "interfacial bearing load" of the connection, making it stronger.

Before the pipe ends are connected, a lubricating sealant, normally a specially formulated epoxy, is applied to the OD surface of the pipe ends and the ID surface of the coupling.

With a patented positive-seal field joining unit, the pipe is then hydraulically pressed into the coupling to a premarked insertion depth-one half of the coupling length-producing a connection with a metal-to-metal seal.

The epoxy lubricates, prevents metal galling during coupling installation, and cures to form a secondary seal around the pipe ends and throughout the ID of the coupling. A shaped spacer-ring gasket can also serve as a bumper between the pipe ends to prevent damage to the pipe's internal coating, if any.

Jetair says that, as an associated benefit, an independant third seal is formed when the spacer-ring gasket is energized between the pipe ends upon completion of connection makeup.

With no overlapping of pipe ends, each joint retains its original length.

Jetair says that other joining methods, such as the "bell and spicket" method, can reduce pipe up to 1 ft/connection in insertion depth alone, as well as reducing line pipe ID, with a resulting reduction in flow characteristics.

Those techniques also "cold work" the pipe ends which produces longitudinal stress risers in the "bell" as a result of the swedging operation. Stress risers cause the loss of expensive pipe due to "split ends" and increase the chances of sulfide-stress cracking and corrosion.

Because the positive-seal coupling system completely eliminates the need for welding, pipelines can be built with the benefit of internal coating which protects them from corrosive fluids and enhances product flow.

Internal pipe coating also prevents formation of iron oxides, iron sulfides, and other common bare-pipe contaminants.

The coupling system is used in highly corrosive pipeline applications including CO2 injection, water injection, brine-water disposal wells, plus the produced fluids of oil, saltwater, and natural gas containing H2S and CO2.

To date, of the 85,000 Jetair connections currently in use, says the company, more than 4,500 have been installed in near-shore or offshore Gulf of Mexico.

Typical was the use of 670 connectors used to install piggybacked 3 and 4-in. lines (oil and natural gas, respectively) on Vermillion Block 16. Installation was in November 1994 for Fina Oil & Chemical Co., Houston (Fig. 6).

Snap-ring connectors

Hunting's recently developed PosiConn is an example of snap-ring connectors (Fig. 1d [89070 bytes]).

These use snap rings held in the coupling and engage into grooves in the pipe. A metal-to-metal seal and secondary "O" ring seals are provided.

References

1. Panayotti, Alex, and Snell, David, "Mechanical Connectors for Offshore Pipelines," Energy Week, Jan. 30-Feb. 2, Houston.

2. Kennedy, John L., Oil and Gas Pipeline Fundamentals. First Ed. (Tulsa: PennWell Publishing Co., 1984), pp. 183-84.

3. Sikes, Jim, and Roche, Joe, "Deepwater Pipeline J-Lay from a DP Drillship Using Threaded Connections," presented to Deep Offshore Technology 8th International Conference and Exhibition, Oct. 30-Nov. 1, 1995, Rio de Janeiro.

4. Panayotti, Ales, "Qualification testing of FRP lined pipelines," Pipelines '95 Conference, Dubai, November 1995. Copyright 1996 Oil & Gas Journal. All Rights Reserved.