Shaping a competitive Indonesia Pt. 2

Project Director: Ines M Nandin Text and research: Robert Murillo and Arthur Thuot

Continuing “Shaping a Competitive Indonesia: The prime importance of building a sustainable O&G sector,” this second of a two-part special report examines three key industry developments: Alternative fuels, and the myriad ways of shaping tomorrow’s energy needs; Equipment, the building blocks on which strong fundamentals rely; and EPCM companies, changing the landscape of Indonesian O&G.

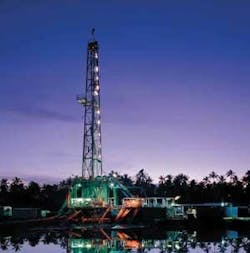

INDONESIA’S ENERGY SECTOR: MATURE BUT INNOVATIVE

Policymakers, executives and international investors have their eyes on how Indonesia’s oil and gas industry, which generates almost a quarter of the country’s $100 billion export base, can achieve sustainability and competitiveness, ensuring financial security and identifying new opportunities in one of the most underrated economies in Goldman Sachs’ Next Eleven. As the oil fields mature and more investment-heavy state-of-the-art technology is required for exploring further afield, the two main challenges ahead for Indonesia’s energy future are diversifying the resources and solidifying the country’s local equipment and engineering players.

Purnomo Yusgiantoro, Indonesia’s Minister of Energy and Mineral Resources, addresses these opportunities in highlighting the country’s market structure: “Indonesia’s oil and gas sector will grow through a combination of companies foreign and local, big and small. The country is undergoing a similar evolution to what was seen in the United States and other oil producing nations, where an initial domination by the ‘Seven Sisters’ gives way to the emergence of aggressive independent risk takers and eventually to smaller niche players. As a consequence, Indonesia’s O&G sector has become very competitive and full of companies of different shapes and sizes.”

Of these different shapes and sizes, it will be those at the larger end of the spectrum – and their partners – which will be looking to capitalize on the industry’s most exciting and prospective areas in Eastern Indonesia, where deepwater exploration requires high capital investment but could offer high returns. Acknowledging this is a great opportunity, Suyitno Patmosukismo, Executive Director of the Indonesian Petroleum Association (IPA), explains that “With the high price of oil (and followed by the high price of gas), companies are more than eager and able to invest”, and suggests that the main challenges to overcome in order to materialize this investment have to do with harmonization between a variety of laws, including areas in oil and gas, taxation, and forestry.

Abdul Muin, Vice-Chairman of upstream oil and gas regulator BP Migas, comments on the organization’s commitment to creating a favourable investor climate. “BP Migas understands that frontier activities are very expensive and technically challenging to investors, and we are quite generous in giving incentives as long as the economics are viable for both parties. Undoubtedly, in encouraging investors to explore the deepwater areas, we must give support, and BP Migas will be a strong yet flexible partner in consideration toward these activities.”

Faced with questions regarding the industry’s sustainability, Minister Purnomo remains confident, stating that “compared to many other energy exporting countries, many of which only have important oil reserves, Indonesia is in a good position thanks to its abundance of different energy sources.”

However, these sources – ranging from organic substitutes such as biofuels, to new potential in coal bed methane (CBM) – are not without their complications. While oil prices reaching $100 barrel encourage exploration for other options, roadblocks such as subsidies, high upfront investment, and lack of technological innovation hamper the development of domestic innovation. Regardless, Indonesia perseveres, and as Purnomo puts it, will continue along a path of “diversifying the energy sources in order to reduce the reliance on oil products for domestic energy consumption. The government is therefore encouraging a shift towards non-oil energy sources which are fortunately numerous and abundant in Indonesia.”

A need to ‘fuel’ the alternatives

Indonesia is at a crucial juncture: its growing economy needs to satisfy its thirst for energy. In looking towards different ways of pleasing its power demands, Purnomo clearly articulates his country’s alternative fuel potential: “Indonesia is a country that is rich in fossil fuels but we are encouraging diversification into alternative energy sources. The main obstacle to the development of renewable resources like geothermal – with a potential for 27 000 MW and current level at only 800 MW – and biofuels is actually the subsidy system for petroleum products, which makes it very difficult for these alternative energies to be competitive on the market. This is an issue the government is addressing through fiscal incentives and other mechanisms, in order to allow the country to tap into its full range of energy sources.”

Despite long-term plans to reduce subsidies and reform the system, constant delays coupled with soaring fuel prices have resulted in a significant – and controversial – burden on state budgets. Many critics blame the subsidy’s cash drain for shortfalls in much-needed investment for infrastructure, education, and poverty alleviation. Initial estimates of 2008’s total subsidy cost of 45.8 trillion rupiah ($4.9 billion), based on lower historical prices, have been revised to upwards of 106.2 trillion rupiah ($11.60 billion), reflecting the actual expected cost of maintaining state support in a bullish energy market.

Although Purnomo contends that skyrocketing energy prices provide a positive windfall for the economy, many experts warn that even in this context, the fuel subsidy is unsustainable. James Castle, who has spent over 30 years in Indonesia as an economic advisor and Director of market entry strategy consultancy CastleAsia, explains: “The minister is correct in saying that the numbers are net positive, but this balancing act comes at a huge cost because of large subsidies for domestic fuels. The subsidies are fiscally sustainable at current prices but not wise, and tremendously distortive. They are one of the key reasons the sector has not grown domestically.”

Although the government’s hesitation to change politically sensitive subsidies discourages broadening Indonesia’s energy horizons, eventual change implies a strong hope for the future. According to Purnomo, “based on our current situation and Indonesia’s natural resources potential, the government has elaborated a target scenario for the national energy mix in 2025 that would consist of: 33% coal, 30% gas, 20% oil, and 17% renewable energies (of which 5% geothermal, 5% biofuels, and the remaining 7% a combination of biomass, nuclear, hydro, solar, and coal liquefaction). That is the goal towards which we are working, through 5 year programs gradually developing the different energy sources in order to make the scenario a reality.”

Biofuels, a feasible green solution?

Indonesia's rich biodiversity and vast potential for the development of biofuels is a tempting apple for national and international actors. The authorities know this and are keen in developing strategy and incentives for investment. Companies have been lining up to negotiate deals for the development of biodiesel and bioethanol projects in Indonesia, following the inclusion of biofuels with 5% of the targeted Energy Mix for 2025 and the Presidential Instruction No. 1/2006 on the provision and utilization of biofuels as an alternative energy source. The government’s commitment to biofuel development has also resulted in the creation of the National Team for Biofuel Development (BBN) charged with expediting the country's adoption of biofuel.

Al Hilal Hamdi, Chief Executive of BBN, points out that in January 2007, "60 commitments were signed by investors for biofuel projects worth about 12.4 billion dollars. Since then, a few more have been signed, and here at BBN we are constantly receiving potential investors interested in learning more about the opportunities". Seven local banks and several foreign financial institutions such as the Japanese Bank for International Cooperation (JBIC), the Interamerican Development Bank (IDB) and the French Development Bank (AFD) have all committed to give financial support to biofuel programs in Indonesia. In Hamdi's view, biofuel development can offer a complete solution to the 'triangle of challenges' which Indonesia and so many other developing nations face: energy security, poverty and environmental deterioration.

As ideal as all of this seems, actually implementing the policy for biofuels in a country as vast and complex as Indonesia encounters many challenges. "Although initially there has been a very big interest in biofuel development from companies from the industrial sector, given the uncertainty and slow pace of progress in regulations this excitement is likely to diminish", says Donny Winarno, Vice President Corporate Sales & Marketing of Molindo Raya Industrial, a leading ethanol producer in Indonesia. Other important obstacles include large scale availability of feedstock, lack of adequate infrastructure, and, in the case of biodiesel, soaring cost of crude palm oil (CPO).

Nonetheless, Molindo Raya is actively developing its bioethanol business in the country and sees enormous growth opportunities once the regulatory framework for the sector is settled. In fact, Molindo Raya is a pioneer in biofuel production in Indonesia since 2004, which allowed it to become supplier of choice for Pertamina's (Indonesia’s state oil and gas company) "Pertamax" blend (including 3.5-5% ethanol). Volumes are still relatively small as it has to coexist with the highly subsidized regular fuel at the pumps, but as the government phases out the subsidy over the coming years Pertamax should gain in competitiveness.

With plans of building at least 2 new ethanol plants by 2012 in Indonesia, "Molindo Raya wants to continue as leader in ethanol and be at the forefront of biofuel business in Indonesia. This is a global and irreversible trend; therefore biofuels are destined to become a part of life for everyone around the world", concludes Winarno.

The alchemy of CBM: turning coal into gas

The magic formula for energy sustanability is diversification of power resources, and many in the Indonesian government see CBM as potentially one of the country’s main alternative energy sources of the future. Despite its strategy to divest non-core business units, Pertamina has decided to keep its geothermal activities and is betting on the development of CBM. CBM is a relatively young industry and scientific understanding and operations are in the early stages. To attract investors, the government is offering a split which is different from oil and gas contracts, depending on the areas and particular conditions. Pertamina is working on a CBM pilot project in South Sumatra with Shell and the support of the Indonesian Research and Development Center for Oil & Gas Technology (LEMIGAS). Hadi Purnomo, LEMIGAS director, considers that CBM potential in Indonesia is very promising, “as it will increase national gas reserves and contribute as an energy back-up in the near future. The development of CBM will also be of great economic, social and ecological benefit”.

As the leading R&D institution for the oil and gas sector in Indonesia, LEMIGAS has been contributing to the country’s energy development since 1965. It conducts applied research in a wide array of areas in both upstream and downstream, providing the government crucial technical and scientific input so that it can make the optimal policy decisions. LEMIGAS also plays a key role by helping solve industrial problems, developing new technologies and acting as an independent arbitrator when technical differences of opinion arise between the government and O&G companies (or among themselves).

With 70-80% of Indonesia’s oil producing fields at a mature stage, LEMIGAS is focusing much of its attention on helping companies optimize production through Enhanced Oil Recovery (EOR) technology. To this end it is actively partnering with local and foreign players in order to advance R&D for different techniques in the field, such as an initiative with Japan’s Sojitz Corporation to develop CO2 injections for EOR. Another example of cooperation is with Petrochina’s Research Institute of Petroleum Exploration and Development on technological services and field implementation of chemical injections for EOR. LEMIGAS is also collaborating with Heriot Watt University on flow assurance and natural gas hydrate technologies.

Although LEMIGAS is a public institution with obligations towards the government, it also has business activities and is independent to a large extent in its growth strategy. LEMIGAS’ capabilities span a broad range of services in exploration, production, and gas processing and transportation. As Purnomo is quick to highlight, “we provide services for industry clients, which represents about 30% of our current revenues and is increasing. LEMIGAS aspires to take this number to 40% in the near future”.

Stepping on the gas…

VICO, the third largest production-sharing contract operator in Indonesia, has also smelled gas. “Looking toward the future, the investment VICO is making in the existing reservoirs is good, but we started to wonder if there was anything else out there. In 2004 we started to recognize CBM potential, and subsequent studies revealed that VICO actually has the highest and best potential in Indonesia, in the Sanga-Sanga block. Every single well drilled in the block passes through a layer of coal containing gas. VICO knows the gas is there, and believes is present in considerable volumes,” says its President and CEO, Chris Phillips.

VICO Indonesia, the brain child of European giants BP and ENI, is interested in developing an alternative resource, with the view to quickly boost production and revitalize a company whose PSC is up for renewal in 2018. With the 1972 discovery of gas in Badak, VICO solidified its position at the forefront of the Liquified Natural Gas (LNG) industry, and initiated the trend towards Indonesia’s leadership as an LNG exporter. Currently a 50-50 joint venture between BP and ENI, VICO’s primary asset is East Kalimantan’s Sanga-Sanga block, with over 500mcfpd expected gas production in 2008, which confirms the company’s expertise of onshore gas in East Kalimantan. “We manage the whole pipeline production system for all of East Kalimantan, all of Total’s and Chevron’s production, and we are a 20% owner in PT Badak, which operates the Bontang plant,” referring to one of the world’s largest LNG plants, with a capacity of over 20mtpa, and a sizeable production record of over 227 million tonnes of gas exported to countries like Japan, Korea, and Taiwan.

Raw amounts notwithstanding, there are other factors at play in determining the feasibility of gas extraction from layers of coal hundreds of meters below ground. Third-party geological surveys have concluded countrywide reserves exceeding 450tcf of CBM potential, but this figure is highly susceptible to variation associated with high development costs and unattractiveness of greenfield developments. “The real challenge with CBM is how permeable the coal is, and whether gas is producible in economic quantities and rates. Generally, coal needs to be dewatered before gas is produced. This has two unfavourable consequences, of environmental concerns as well as large upfront expenditures,” Phillips notes, underscoring the challenges associated with the possible developments.

However, despite potential downsides, Phillips is quick to counter. “Unlike gas production from conventional sands, CBM output tends to increase with time as water volume goes down. VICO realizes there is a lot of opportunity, and has been lobbying the government over the last year, making it known that we are ready to bring CBM aboard. VICO believes it can go into testing, appraisal and development of CBM very quickly. What is important is that the marketplace is hungry for gas, and will be desperate for gas in the next 10 years. Anything VICO can bring to the marketplace is going to be beneficial for us, but more so for Indonesia. In the end the country will always benefit more than the contractors.”

Indonesia’s Equipment Needs: The right technology at the right time

As the oil and gas sector goes through a global boom thanks to record-high prices and strong demand from large emerging markets, companies like VICO are increasingly turning to technology in enhancing operations across operations. Maximizing production from ageing fields “is the kind of area where VICO has an advantage in innovating with new ideas, and involves a new, different, and smarter investment,” says Phillips. “Indonesia as a country is less a place of testing new technology, and more a place of implementing new technology, such as horizontal wells, cluster wells, and fracturing, which is currently in trial and could provide further reserves from deep in VICO’s reservoirs.”

Likewise, the world's supplying industries are building up specialized capacities in order to service this lucrative sector. Indonesia's long history in oil and gas and the open nature of its upstream in particular have allowed for all of the major technological leaders to establish their presence and compete for business and establish partnerships. Though considerably affected by the financial crisis and instability of the late nineties, companies such as ABB, Endress+Hauser and Siemens have rebuilt their operations in the country and are paying special attention to opportunities across the value chain of the Oil & Gas sector.

Similarly, the Belgium-based global provider of industrial productivity solutions, Atlas Copco, feels that after China and India, it is time to put Indonesia in the spotlight. This enthusiasm is based not only on the country's large population and high levels of growth, but also on the dynamics of the mining, oil and gas and raw materials sectors. Though originally more concentrated on the industrial sector, in 2006 Atlas Copco decided to focus on the oil and gas industry.

"Our products are already well known in the international O&G sector and our achievements in terms of quality and environment are acknowledged. This is not yet the case completely in Indonesia O&G industry where we are relatively newcomers, so our chances of success with contractors are higher among foreign firms for the moment", says Hakam Bergstrom, Director of Atlas Copco Indonesia. Well aware of the fact that the compressor market is very competitive, Bergstrom stresses that, "what makes Atlas Copco the world leader in compressor technology and a preferred partner is that we place our brand name and responsibility behind every single action we make, moreover we can always count on the backing and resources within the Atlas Copco Group".

Atlas Copco has already worked with major oil companies in Indonesia such as Chevron, ConocoPhillips, CNOOC, BP and Total. In the context of the company's focus on the O&G sector, it is offering clients custom design for special requirements, collaborating with both its global and local engineering centres, and increasing its local staff. Bergstrom points out Atlas Copco's special rental service division, "which is moving from the common market to more sector-specific niches. This shift is driven in particular by the Air Power special rental models division in areas like the US, and also through acquisitions of other companies working in the field". Indeed, Atlas Copco's current strategy combines both organic and external growth, all while striving to keep everything related to its core business in-house.

"Our main challenge today regarding the oil and gas sector in Indonesia is to live up to the reputation already obtained in other industries through decades of satisfying customers", affirms Bergstrom. Now a company active in all the major markets around the world, Atlas Copco's challenge is to maintain its culture and high standards regardless of location, all while adapting to the specificities of each country. "We still have some hard work to do before we can claim our position as #1 service provider in Indonesia, so our challenge is to be there within 3 years", says Bergstrom.

Turbines, the industry’s motors

Indoturbine, created 35 years ago following a swell in the Indonesian oil and gas industry, is riding the crest of another wave, supporting major PSCs such as Total E&P Indonesie, Hess, and Kangean Energy Indonesia. Offering insights on the impact of this momentum for local equipment players, Wantya Sapardan, President Director of Indoturbine, remarks: “The oil and gas industry is very cyclical, and Indoturbine is proactive in terms of anticipating market changes. Indonesia’s growth tends to be delayed by a year or two compared to the rest of the world, which means that although momentum in global oil and gas sectors started in 2003, Indoturbine began seeing substantial growth from 2005 onward. The upside of this delayed reaction is that by starting late, Indonesia also finishes late, and therefore while global markets may be currently poised for a downturn, Indoturbine foresees strong growth through 2009.”

As the exclusive Indonesia distributor of Caterpillar’s Solar Turbines brand, Indoturbine has, since its inception, “continuously developing the scope of Solar Turbines in Indonesia, through after-sales service and maintenance support, and investments in inventories and repair facilities,” including turbine overhaul and compressor repair and re-staging services in Bandung, which Sapardan summarizes as providing his clients “on-site, high-quality local service offers easier access to equipment, reduced turn-around time, and ultimately cost savings.”

In addition to traditional competitors like Siemens, GE, and Rolls Royce, companies like Indoturbine are facing rivals from upstart China, undercutting on price and emerging as surprisingly competitive in materials technology. However, Sapardan remains confident that potential clients are more concerned with factors other than price, noting “Indoturbine has been in business since 1973, which gives us the edge over our competitors in terms of local support. We can offer a complete package, from understanding client needs at the outset, through to installation, testing, and after sales support with operations and maintenance. In achieving our vision to be recognized as a valued partner in the energy and industrial development projects throughout Indonesia, Indoturbine strives to become a solution provider that delivers the best product alongside a full range of maintenance and repair operations.”

In fulfilling such on-site services, Sapardan notes that Indoturbine has “17 specialists in-field who can carry-on small EPCM projects for installation of compressors. These Indonesian engineers provide the local content mandated by the government, so that while the technology may not be sourced locally, the knowledge that goes into the after-sales support and engineering services is 100% Indonesian.”

Establishing such a base of local Indonesian talent does not come easily, and Sapardan echoes an industry consensus of difficulties in recruitment and retention. “If companies in countries like Qatar, for instance, want to pay Indonesian engineers higher salaries, there is no way Indoturbine can match their offer. However, there are factors other than salary when engineers choose where to build their career. Indonesians are loyal to their families, their culture, and country, and moving to Qatar may not always be the most attractive option when all elements are taken into consideration.”

Commenting on the domestic opportunities present for companies like Indoturbine, Sapardan concludes, “Indonesia lacks energy infrastructure, so in addition to continued diversification of our activities toward different services is our goal of becoming a true Energy Solution Provider. Clients do not want to buy a gas turbine compressor or a gas turbine generator per se; they need to move oil or gas from one point to another point, or they need electricity, and Indoturbine can provide it.”

EPCM, Indonesia’s other frontiers.

Smaller local Indonesian engineering companies are also seeking to conquer new frontiers to thrive in the energy market, or so says Triharyo Indrawan Soesilo, President Director of local EPC company PT Rekayasa Industri: "the first is offshore construction, which is a very challenging sector still dominated by foreign companies; and the second is related to the machines and equipment we need to import, an area in which industries and engineers in Indonesia should work together so that the country can become more self-sufficient in terms of capital goods for oil and gas projects".

According to Soesilo, the global boom for EPC business made many international companies focus on the most dynamic regions such as the Middle East, therefore leaving more space for local companies like Rekayasa to take on projects in Indonesia. Already used to competing with big international EPC players in Indonesia, Rekaysa is also learning from their experience in order to project itself overseas.

The company has been involved in some of Indonesia's most important projects all over the value chain of the oil and gas industry for decades, and has been a pioneer in areas such as geothermal and biofuels. Currently its main activities focus on upstream energy projects such as geothermal, coal-fired power plants, as well as facilities for gas compression and distribution. In downstream, it is working on several projects with Pertamina on the revamp of existing refineries and lube oil blending plants. In addition, the company is participating in biofuel projects with Medco (bioethanol) and Wilmar (biodiesel).

BP Migas’ Abdul Muin concurs with Mr. Soesilo’s comments, noting the importance of equipment and associated regulations to EPCM companies, stating “BP Migas and the Department of Energy are very aggressive and the response from other departments is also very good in this regard. Upstream business prospects are very promising, and with continuing improvements in government regulation and a spirit towards improving investment climate, it’s a good beginning.”

This optimism is shared by many EPCM companies, and PT. Dwisatu Mustika Bumi (DMB) is no exception. Created in 1993, DMB has quickly moved up into the ranks of major Indonesian marine-offshore companies, participating in correspondingly larger tenders as a result. With increased oil prices creating interest in reactivating newly-profitable oil fields, and a $21 million contract with BP, DMB has carried this momentum forward by recently launching a project with Pertamina to build the $42 million Balongan oil terminal. Elaborating on this latter contract with Indonesia’s NOC, Chairman Halim explains, “For this project, DMB is building two offloading offshore terminals, what we call single point moorings (SPMs), and a pipeline to the shore. Onshore, DMB is building a tankfarm with all associated equipment. Additionally, the project required a custody transfer facility, because from Balongan oil is transferred directly to Jakarta due to congestion cutting off intake points. As there is insufficient space in Jakarta, DMB built this facility in Balongan, where the oil is stored in the tankfarm prior to transfer.”

While growing in size, DMB has also grown its commitment to HSE, being ISO certified and receiving commendations from clients like Star Energy. Describing DMB’s philosophy toward safety matters, Halim notes that “Accidents mean costs, and that’s why DMB avoids them. Every time, before anyone starts working, we always stress to do everything safely. DMB’s motto is ‘Safety Is Our Priority,’ and we take safety very seriously: DMB has achieved over 7.5 million man hours with no lost time.”

Indonesian projects in search of local expertise

Back in 1994, Bambang Gyat, co-founder and Director of Enerkon, an Indonesian engineering and project management firm, asked himself this question: “this country has had the people and the oil and gas resources, so why weren’t locals engaged in the process?” His message was clear: “My vision was to develop engineering strength in Indonesia. I knew that Indonesia had engineering potential.”

In trying to engage the locals, Gyat was sometimes not well-received. “In the beginning, Enerkon would often receive sceptical questions: ‘What can you do for me?’ to which we would respond, ‘Don’t worry, we can do it.’ And then we’d deliver, in a way that encourages and empower local engineering resources in the energy and oil and gas fields.”

Gyat’s strategy seems to have worked, as evidenced by Enerkon’s involvement on major projects in recent years. One such project is the $1.3 billion South Sumatra-West Java pipeline, for which Enerkon is performing co-project management and consulting services. Explaining the rationale behind Enerkon’s selection for this massive infrastructure development, Gyat explains: “Because it is an Indonesian project, there is a requirement for Indonesian engineers, and that’s where Enerkon fills the niche: local engineering expertise.”

Indonesia’s vast oil and gas sector has also created opportunities for local companies further down the value chain, particularly in downstream activities. Aditya Nugraha Pratama (ANP) is a prime example of this, with a highly diversified portfolio including the import/export of oil products for Pertamina and the distribution of bulk fuel for industry. ANP is also involved in the trading of Pertamina lube base oil and has recently launched its own brand of lubricant called Perri.

ANP’s founder and President Director, Mustafa Kamil Thahir, accomplished one of the biggest dreams in his life when he created the company in 2002. Initially focused on trading and other downstream-related activities, this entrepreneur has expanded ANP’s scope of business to engineering & project development, and most notably to the upstream sector. In March 2007, ANP Energy together with a strategic partner was awarded the offshore Lampung 1 PSC by upstream regulator BP Migas, where it is currently carrying out exploration work in hopes of passing to development in the future.

“After several years of successful growth in the trading business, I decided to take a chance in the field of E&P. This is a potentially a very lucrative business, but also entails high risk, so for now we are concentrating on the fields we have and will see what happens next”, states Thahir. Though this adds a completely new dimension to ANP’s activities, Thahir is always looking for new opportunities arising in Indonesia’s O&G sector as it goes through fundamental changes, particularly with the liberalization in downstream. In fact, ANP is already considering new business ventures in petrochemicals and aviation fuel.