Real-time well optimization stabilizes, adds production

Several field cases show how Shell Group’s use of software for monitoring and optimizing production has reduced decline rates.

Software data-driven well models allow prediction of changes to overall and individual well production because of changes to individual well set points such as production choke settings and lift-gas rates. The software then computes well set points for optimizing oil and gas production subject to various well and production constraints, thereby:

- Decreasing field decline, sustained during several years.

- Increasing production by reducing platform start-up time.

- Providing more stable well production.

Production measurements

In conventional practice, operators measure individual well oil, gas, and water production weekly or monthly basis in shared well test facilities. The net effect is that well measurements represent only about 1% of the production and operators assume that the wells produce at the same rates for the remaining 99% of the time.

This assumption leads to many production management problems. Hence, management of oil and gas production from a cluster of wells is difficult and leads to late diagnosis of production problems and slow and conservative handling of production constraints.

A software application developed by Shell Global Solutions (FieldWare Production Universe) provides continuous real-time estimates of well-by-well oil, water, and gas production. The software bases its estimates on data-driven models constructed and updated from production well tests and real-time production data.

The software is cost effective and fast to deploy because it uses existing infrastructure.

This article addresses application of the software’s data-driven techniques for well and process optimization. For optimization, the data-driven well models allow for the prediction of the changes to overall and individual well production because of changes to individual well production chokes, lift-gas rates, or other similar set points. The software then computes the set point for optimizing oil and gas production subject to various well and overall production constraints.

Software background

The software is a data-driven modeling application developed by Shell. A previous article (OGJ, Mar. 5, 2007, p. 49) described the development background and early operational experience of the software within the Shell Group.

To improve on problems with periodic test separator measurements, operators have used several approaches combining a well’s physical models with real-time wellhead pressures and temperatures to predict three-phase flow in real time or near real time.

In practice, operators found a well’s physical models difficult to set up, calibrate, and maintain in an operating environment.

The data-driven software approach, in contrast, takes advantage of the well test and available production metering in conventional production operations, and addresses operational sustainability issues related to physical models for well production surveillance, particularly for changing well conditions and instrumentation uncertainty.

The software requires an input of an abbreviated multirate well test along with historic well test results for the modeling process that generates the data-driven well models. These models relate the three-phase flow from the well on test with signals from the wellhead instrumentation such as tubinghead pressures and temperatures, lift-gas injection rates, and production choke openings.

The software application has intuitive graphical user interfaces for operator data load and display and well model configuration and validation with minimal training. The software’s underlying concepts are simple and have a clear relationship to the familiar well testing process.

Data from subsequent well tests automatically upload into software for model validation or updating. Algorithms within the software automatically indicate when a model requires updating.

Use of data-driven models for well production surveillance has several advantages, including simplicity of approach and how it incorporates and extends the conventional well testing process. The process requires no numerical assumptions about the underlying physics of the well.

In addition, because operators often infrequently calibrate wellhead instrumentation, one benefit of this software is that it requires only repeatable well measurements within limits. Absolute measurement accuracy is not critical.

To ensure robustness, the software creates several independent models for each well with different inputs. This allows well estimates to continue even if an individual instrument fails.

The net effect is that the software’s real-time well flow estimates, comparison with bulk measurements, fallback models, and graphical user interface provide:

- Daily production and deferment totals for individual and collective wells.

- Real-time cross-check on the quality of the estimates, indicating need for retesting, and identifying instrumentation problems.

- Well flow estimates when the wells are not on test by streaming real-time well data to the models. The models also compare automatically the sum of the estimated well production with real time, single-phase flows as physically measured by export or bulk meters

- Daily allocation factors.

- Fast and cost effective implementation.

Optimizer

Operators can also use the data-driven models for continuously estimating well flow to predict well production for given values of well production variables, such as choke position, lift-gas injection rates, and pump speed. The software optimizer uses data-driven models to optimize estimated oil production for a given well by computing the choke or lift-gas set points for maximum oil or gas production from that well alone, while considering constraints, such as:

- Gas-liquid or gas-oil ratio at a value required for good reservoir management.

- Lift-gas injection rate within prespecified limits.

- Production separator liquid handling capacity.

- Produced-water disposal capacity.

- Lift-gas compression capacity.

- Gas export demand or export compression capacity.

- Gas or oil export constraints due to pipeline issues or pump maintenance.

- Venting and flaring constraints.

- Minimum produced water requirements to support water injection for pressure maintenance.

- Injection voidage replacement limits.

Further, limited production system capacity can translate also into increased well production pressures, for example, due to restricted gas handling capability in the production separator. In such cases, high gas production from one well may result in a higher common header pressure, thereby backing out production from other wells.

The optimizer emulates these well interactions by generating data-driven header pressure vs. fluid production rate models and then combines and uses them with the previously discussed well models.

Daily production optimization determines suitable well set points to maximize production subject to applicable well and facility constraints. Common optimization problem formulations include:

- Maximizing net oil production with limited lift-gas availability, for example, lift-gas compression outage or failure.

- Maximizing net oil production while meeting gas export nominations.

- Maximizing condensate production while maintaining gas export nominations.

- Optimizing the short-term facility revenue, for example, if the facility exports both oil and gas and the software knows the relative incremental fiscal revenue values of the oil and gas streams.

With the discussed production targets and constraints, plus the models of the wells and the headers, the optimizer can then automatically compute optimal lift gas or production choke set points.

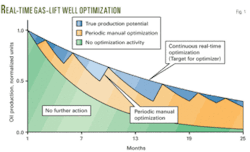

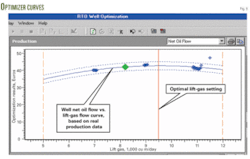

For gas-lifted wells, Fig. 1 illustrates the generation of daily set points and on-demand production to sustain total production at field capacity.

The software also may use the optimized set points to provide optimal response to changes in the production system, for example, when gas demand drops, or when a lift-gas compressors trips.

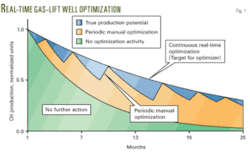

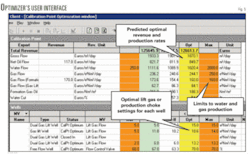

The software provides the operator with set points for manual entry into the control system, or passed to the control system, directly or through a middleware layer such as a process historian (Fig. 2).

Maintenance of the optimization models requires multirate well testing for well flow estimation.

When a production upset occurs, the optimizer, when set, can detect the resulting change in the system constraints, and compute optimal well set points. If the operator shuts in temporarily the well, such as for wireline activities, the optimizer can compute new optimal set points for the remaining wells.

Case studies

Several Shell production facilities have deployed the optimizer. In one case, the optimizer is on an offshore production platform with 15 gas-lifted wells.

On this platform, all wells have tubinghead transmitters, and six of the largest producers have downhole pressure gauges. The wells also have closed-loop flow controllers on their lift-gas injection lines.

Data transmitted from the platform go to other platforms and ashore. This allows operators to monitor the production data in real time and to change the set points for the lift-gas flow rates individually and remotely from the onshore control room.

After setting up and applying the initial well models, the operators observed elevated production header pressures, indicating much interaction between the wells. Hence, they used the optimizer to model the well sensitivity to changes in header pressure. The optimizer computed optimal well lift-gas set points to maximize gross production, taking into account header interaction, backpressure effects of gas production, and lift-gas injection rate constraints.

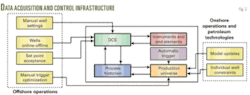

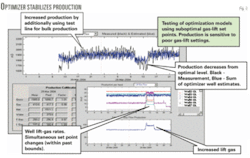

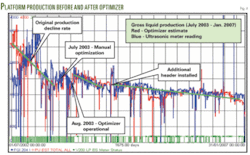

To verify the benefits of the optimizer, the operators conducted a sensitivity analysis on the lift-gas rate. Fig. 3 illustrates a case in which the analyst simultaneously changed the lift-gas injection rates to suboptimal settings, resulting in production decline in spite of an increase in lift-gas injection. This validated the value of the optimizer.

The optimizer modeling and quantification of gas-lift header pressure effects indicated the need for an additional flowline to minimize backpressure effects. When installed, the additional header helped reduce backpressure that led to a corresponding production increase.

The optimizer application decreased production decline. Fig. 4 shows the 5-year trend of platform production before and after optimization. The trend confirms that the use of the optimizer has led to more stable operations and has reduced production decline.

Shell also has deployed the optimizer in onshore fields. One such production facility is in a heavily populated urban area with one gas well, five free flowing oil wells and nine gas-lifted wells. The oil goes to a nearby refinery and gas enters a local gas grid.

The location does not allow venting, flaring, and surface water disposal; hence, these limitations constrain production. Other constraints that limit total gas production are export and lift-gas compressors availability and the gas offtake rate.

The field also has to produce a minimum amount of injected water for reservoir pressure maintenance. The constraint on water production, however, is from a combination of water injection and water disposal capacity.

Gas sales detract from lift-gas required for oil and water production. Due to the direct supply of gas to the gas grid, the gas offtake can change on minimal notice.

Shell constructed optimizer models for all of the wells and incorporated the overall production constraints such as export gas limits, compression capacity, and water handling capacity (Fig. 5).

Because the field exported both oil and gas, Shell configured the optimizer to optimize on incremental revenue from oil and gas sales.

Since introduction of the optimizer on the production station, the daily production stabilized. Fig. 6 shows the optimal set points derived.

A third case illustrates another application in an offshore oil production facility.

This offshore platform produces 6,000 cu m/day of oil and 450,000 cu m/day of gas from 33 platform wells and two subsea tiebacks. The platform for power uses about 60% of the gas production. All wells are on gas-lift and have water cuts ranging between 10 and 95% with an overall 78 cu m/cu m GOR.

Lift-gas optimization on the platform was a process that had evolved over time. The process involved a large number of users and data flows. Users only were aware of their part of the process and different shifts used different optimization processes.

The new optimizer provides a more consistent and transparent process. Onshore-based petroleum engineers determine the models and rules for the optimization and a production server solely holds all data relevant to optimization for consistent use by all users. The users obtain all optimization data from the process historian and the distributed control system (DCS) receives all optimal gas lift set points via the historian (Fig. 2).

A key business driver for implementing the optimizer was the rate at which the operator can restart a platform after a trip shutdown. Since the implementation of optimizer in November 2006, the platform has experience several trips. The optimizer has enabled platform start-up on average 25% faster than before with a corresponding increase in production.

The authors

Ron Cramer (Ronald.Cramer @shell.com) is a senior advisor with Shell Global Solution, Houston, in oil field automation and production systems. Cramer has 30 years’ experience with Shell International in upstream oil field operations and production systems. He also worked for 10 years as a chemical engineer for Union Carbide and Polysar in downstream research and process areas. Cramer is a graduate chemical engineer. Cramer holds a BS in chemical engineering from Strathclyde University, Glasgow, and an MS in chemical engineering from Waterloo University, Ontario.

Keat-Choon Goh works for the upstream advanced production management group in Shell Global Solutions in the Netherlands. He has about 10 years of experience in oil and gas facilities design. Goh received an MA from Cambridge University and a PhD from the University of Southern California. He is a professionally accredited engineer in instrumentation and controls.

Charlie Moncur is a retired senior production operations engineer with Shell Global Solutions, Rijswijk, Netherlands. During his last 6 years with SGSi, he worked as an R&D team leader for developing real-time applications and other related production management and optimization projects. His experience covers most facets of surface and subsurface production operations and IT development.