Smart, intelligent wells provide real-time well control, monitoring

Advancements in downhole tools and sensors are allowing operators real-time control and monitoring of flow from each separate producing or injection interval in a well. These completions, commonly referred to as smart or intelligent wells, can include one or more of such components as:

- Surface-controlled downhole chokes or sliding sleeves for regulating fluid flow from each completed interval.

- Downhole data acquisition sensors for measuring temperature, pressure, and flow of each interval.

- Data transmission, storage, retrieval, and analysis systems, such as depicted in Fig. 1.

These smart completions let operators react in real time to changes in downhole conditions. For example, if sensors indicate excess gas or water entry from an oil-producing interval, an operator can shut in that interval while still producing from other zones without needing intervention equipment, such as wireline units, coiled tubing units, or workover rigs.

The benefits of this system can be broken down into improvement, enablement, reduction, avoidance, and prevention (Table 1). Fig. 2 illustrates that this technology is a value-creation technology that changes the traditional way reservoirs are exploited.

Several variants of these systems have been installed in various offshore and onshore oil fields that have demanding wells in which intervention is difficult and expensive. Deepwater dry tree and subsea wells are primary candidates for these technologies, although most wells so far have been placed in extended reach wells with multiple production and injection zones.

Multilateral wells are also a potential target for these technologies. Fig. 3 illustrates a proposed multilateral intelligent completion under evaluation for a TAML (Technology Advancement of Multilaterals) Level 6 completion.

But proved reliability of these systems is key for determining how fast the industry will adapt them. The mechanical construction needs to be rugged enough to protect system components from damage, wear, high pressure, and high temperature for a 5-10 year life span, according to Baker Oil Tools. And besides the flow control and sensors, ancillary equipment such as that required for terminations, feed-throughs, bypasses, and splices must be designed to function seamlessly with the main components.

Baker Oil Tools said, "The challenges of moving instrumentation and control below the production packer are daunting. From a mechanical standpoint, the space available in a wellbore has always been limited. This is especially true where sand control is a challenge. From a performance standpoint, a well can be hot, caustic, high-pressure, and, in the case of deepwater and long-reach horizontal wells, a very long way from the drilling rig or production terminal."

Industry consortium

A consortium has been discussing ways to standardize the smart technology with respect to compatible power and data communication protocols, thus avoiding the high cost of each company having to develop its own interfaces. The stated aim of this Intelligent Well Instrumentation Standardization (IWIS) project is to assist the integration of downhole power and communication architectures, subsea control systems, and topsides by providing recommended specifications and standards for power and communication architectures and associated hardware.

IWIS membership includes ABB Offshore Systems Ltd, Baker Oil Tools, BP Upstream Technology Group, Cameron Controls, Chevron Corp., ENI Agip SPA, FMC Kongsberg Subsea, Kvaerner Oilfield Products AS, Norsk Hydro AS, PES (Halliburton Energy Services), Petrobras UK Ltd., Roxar Production Management AS, Schlumberger Ltd., Shell International Exploration & Production BV, Statoil AS, Texaco Inc., Expro Group, Triangle Equipment AS, Weatherford Completion Systems, and Wood Group Production Technology Ltd.

For 2001, the IWIS joint industry project will be managed by Offshore Technology Management Ltd., Guilford, UK.

Guy Woodall of Offshore Technology says that IWIS has made good progress towards producing a revised ISO 13628 Part 6 (Petroleum and natural gas industries, design and operation of subsea production systems). It has split the standard into physical, communications, power, and testing aspects and, at presstime, had expected to complete the revision by the end of its Mar. 14-15, 2001, New Orleans meeting, after which the recommendations will be submitted to the appropriate ISO working group.

He adds that, once the subsea integration standard is completed, IWIS could evolve in a number of ways:

- Disband, because its work was completed.

- Reform from time to time to review the standard on an ongoing basis and update it as technology evolves.

- Move on to develop a standard for integration of surface (topsides) equipment.

- Remain in existence as a knowledge management forum to benchmark and compare best practices in the area of intelligent well interface standardization.

Available systems

Various service companies have developed or are in the process of designing smart or intelligent downhole tools. The main choices for downhole flow control are either hydraulic or electrically actuated chokes or sliding sleeves. To date, the industry has mostly installed hydraulically actuated tools, but electrically actuated systems are becoming available.

In regard to downhole sensors, thousands of permanently electronic pressure-temperature gauges have been installed in the last few years, and in a few cases these have been combined with remotely controlled downhole tools.

Besides the electronic measuring devices, fiber-optic sensors are also becoming available. These sensors can record continuous temperature, discrete temperature, pressure, and flow and can also monitor seismic parameters.

Fiber optics combined with downhole-actuated flow-control devices are at a design stage.

The following describes some of the available tools.

Baker Oil Tools

Baker Oil Tools has launched a complete line of intelligent well systems. Fig. 4 illustrates one of its 5.5-in. downhole assemblies.

Baker does not necessarily develop all of its own sensors, but its downhole assemblies can be run with other vendor sensors. The only requirements are that they be qualified and integrated by Baker for system reliability and integrity. One of Baker's applications, on Snorre field off Norway, is discussed elsewhere in this report (see related article, p. 78).

The systems that it has or is developing are:

- Hydraulically controlled valves and electronic permanent downhole gauges.

- Electrically powered and electronically controlled valves and electronic permanent downhole gauges.

- Various new systems under development that will include fiber-optic or electronic sensors and either hydraulically or electronically controlled valves.

Terry Brussear, marketing director for Baker, says that, to date, the industry has installed four of its hydraulically controlled systems. These have accumulated about 25,000 hr downhole and have been cycled over 55 times. Four more systems have been ordered by Petroleum Development Oman LLC (PDO), and two to three more may be installed in the North Sea in 2001.

He says Baker started developing the all-electric system more than 3 years ago. One of its advantages is that it requires only one feed-through hole through the tubing hanger-christmas tree compared with hydraulic or electrohydraulic systems that require multiple feed-throughs. Baker's packers can accommodate up to six feed-through lines.

Baker's first all-electric system is currently being tested by Petroleos Brasileiro SA (Petrobras), and Baker says Petrobras plans to install that system in a subsea well off Brazil.

Baker has based its downhole flow control on its existing sliding sleeve technology. Its hydraulically actuated sliding sleeves have a full-bore access and provide an open and closed position. Baker also is developing a next-generation adjustable choke capability for the sleeves.

Its hydraulically based intelligent completion consists of hydraulic sliding sleeves and feed-through isolation packers. The hydraulic sliding sleeves are remotely operated from the surface via dedicated hydraulic control lines. The feed-through packers accommodate the control lines necessary to operate the hydraulic sliding sleeves and permanent downhole gauges. All hydraulic control lines and monitoring equipment must be reliably integrated into the system with the appropriate encapsulation and protection.

Two features of its systems are the availability of expansion joints that can accommodate multiple control lines on the outside and a wet disconnect-reconnect that prevents having to pull the downhole completion when pulling the tubing.

Brussear says the wet disconnects-reconnects are a key for developing intelligent gravel-packed wells. This is important, he says, because about 50% of all deepwater wells are gravel-packed.

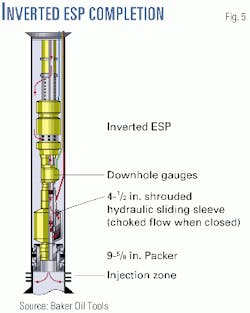

Its first hydraulic system was installed in August 1999 by PDO to manage load on an electric submersible pump (ESP) in a remote area. The inverted ESP injects wastewater back into the formation and eliminates the need for a high-capacity surface pump (Fig. 5).

Baker says that, for the installation, a predetermined physical choke was installed to provide the necessary backpressure to maximize pump life. To eliminate the need for intervention, a shrouded hydraulic sliding sleeve was installed to provide surface-controlled, full-bore bypass of the choke when reservoir conditions permit. With the system, the operator can select the desired injection rate, dependent on backpressure data, and can close the sleeve and divert flow through the choke to save the ESP from over-speed damage if the well becomes fractured.

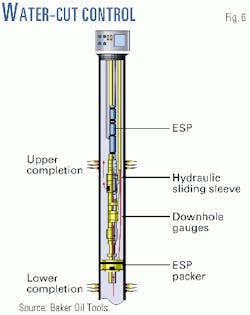

Baker's second intelligent system was installed in December 1999 in a PT Caltex Pacific Indonesia well in Sumatra (Fig. 6). Baker says that before the intelligent completion was installed in the well, water-cut problems made it impossible to produce the well's upper and lower zones continuously and simultaneously. But by having the ability to monitor temperature and pressure in the lower zone and obtaining a transient test, Caltex can use the sliding sleeve to isolate the lower zone inflow, as reservoir conditions require.

Baker says that during the first month after installation, the sleeve was cycled open and closed at least 21 times by remote activation. It adds that, for reservoir management, the temperature and pressure surface readout shows the behavior of the lower zone and allowed production to change from all water to 1,104 bo/d.

Schlumberger

Schlumberger has installed its hydraulic slick-line retrievable flow controllers in 14 wells. The hydraulics have been installed in the following fields: eight in Troll, three in Oseberg, and three in Wytch Farm.

The first all electric system was installed by BP in August 2000 in its Wytch field. A hydraullically controlled flow control valve with flow sensors is planned to be installed in the second quarter of 2001 in a subsea installation off the UK.

Schlumberger's hydraulic technology uses pressure cycles to shift the control valve to metered positions, while the electric flow control valve allows infinite adjustment between opened and closed positions.

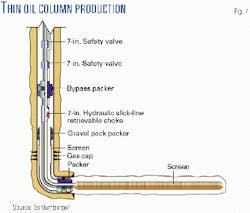

In the Troll wells, the hydraulic flow controller helps produce a 40-ft thick oil layer between a gas cap and water aquifer. John Algeroy, Schlumberger's intelligent-well business development manager, indicates that economic oil production from the subsea wells requires minimal gas production but can accommodate some water production. To produce this zone, the operator opted to drill horizontal, extended-reach wellbores close to the aquifer and as far from the gas cap as possible and to use intelligent gas lift (Fig. 7). The surface-controlled inflow control valve provides variable injection-gas volumes on demand.

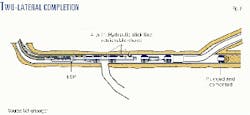

In the first Wytch Farm field intelligent completion, BP drilled two new lateral bores from an existing well to tap reserves from the eastern extremities of the reservoir to recover two pockets of oil bypassed when an older well had watered out, according to Algeroy. BP opted for downhole flow-control capability in each new lateral (Fig. 8).

A valve allows or prevents flow between the well and the inside of the tubing string. The system also includes a downhole Venturi flow meter.

PES

PES (a Halliburton Co. unit) has several types of smart-well control systems. These include all electrohydraulic (with redundancy capabilites), balanced-piston hydraulic, and reservoir-balanced hydraulic.

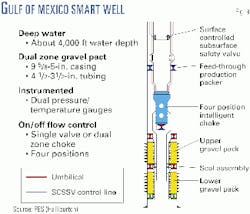

Bill Vidrine, PES intelligent-well manager, says PES has installed 14 of its high-end smart completions. Of these, eight are in the North Sea, two in the Adriatic, two in the Gulf of Mexico, and two in West Africa.

These installations include:

- Eight platform installations, of which five have four valves and control points and one is for injection control.

- Four subsea, deepwater installations with one or two control points.

- Two land installations with four zone infinitely variable control and production allocation capability.

In PES's high-end systems, the control valves are integrated with the pressure and temperature sensors and offer an infinitely variable interval control valve.

Besides the high-end systems, Vidrine says PES also has 38 hydraulic installations in the Far East, Middle East, and South America. These include minihydraulics and direct hydraulics. These systems provide remote hydraulic downhole flow control without the electronics and the pressure and temperature sensors.

To further develop and market smart completions, Halliburton has formed a joint venture with Shell International Exploration & Production BV. The new company, WellDynamics, will have offices in Aberdeen.

PES developed its initial version of its smart completions through a joint industry project with five operators. A North Sea completion in September 1997 was the first downhole field test of PES's SCRAMS assembly. Saga Petroleum AS, now part of Norsk Hydro AS, operated the well.

PES's assemblies are designed to be run in wells having either 95/8-in. casing and 51/2-in. tubing or 7-in. casing and 31/2-in. tubing.

Fig. 9 illustrates the type of completion run in two Gulf of Mexico deepwater subsea wells in the Allegheny field, operated by British-Borneo Oil & Gas PLC, now part of ENI. These electrohydraulic-powered systems provided remote flow control for each producing zone and sensors for monitoring downhole pressure and temperature. The valves are reported to have functioned properly, but the wells are now shut-in due to sand problems.

Roxar

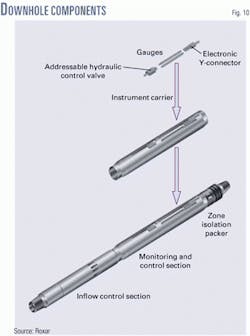

Roxar Ltd., London, also provides a fully hydraulic-operated system to control up to four zones with its present version of the system (Fig. 10).

Harald Schmidt, Roxar manager-business development, says its first system was installed in a Petroleos de Venezuela SA (PDVSA) well in Furrial field in eastern Venezuela. The completion includes 12 pressure and temperature sensors placed on the four control valves.

Schmidt explains that the Furrial field produces light oil from a deep, high-pressure, high-temperature reservoir. He says the Roxar control system provides PDVSA with a simple hydraulic system that allows extensive monitoring of the reservoir.

Later this year, Roxar expects to install a one-level system in a Caltex well in Indonesia.

Fiber optics

Brock Williams, project manager for BP's intelligent-wells project, says that the future holds the promise of dramatically improving the performance of downhole measurements through fiber-optic technology. He indicates that a few first-generation fiber-optic gauges were installed in the North Sea's Gyda and Marnock fields, but these systems suffered from low accuracy and experienced degradation of the optical fiber clarity over time.

But a new generation of fiber-optic gauges and cables are now on the market that offer much improved accuracy-approaching quartz accuracy-and many improvements that have solved the optical clarity issue, according to Williams.

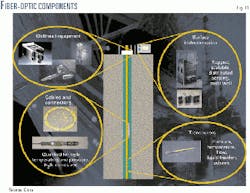

To advance fiber-optic technology, in August 2000, BP and Cidra Corp.,Wallingford, Conn., signed an agreement under which Cidra will provide BP with specialist consulting services to integrate fiber optics into deepwater and other developments, develop new fiber-optic products, enhance capabilities of existing technologies, and integrate multiple optical technologies for specific applications. Cidra will also provide fiber-optic monitoring systems. Fig. 11 illustrates components of a fiber-optic system.

Williams says that, to realize the full value of optical measurements, research is addressing integration of optical fibers into completion components, such as a downhole optical wet connect to allow optical-based measurements across a gravel-packed screen.

A field trial of the new-generation optical pressure gauge was installed in a deviated well in BP's operated Gulf of Mexico Pompano field in 2000.

According to BP, the fiber-optic system is installed much like electronic systems are. The gauge is placed into a mandrel that is typically set in the tubing one joint above the packer. An encapsulated fiber-optic cable connects the gauge to the surface. BP indicates that the rig crew ran the 3.5-in. 13 chrome tubing, cable, and LaSalle clamps at 22 joints/hr. After installation, the downhole fiber-optic gauge and two electronic gauges-one at the surface and one at 4,000 ft-measured depth and monitored a pressure build-up and step-rate test.

BP found that a comparison of the three gauges indicated pressure data acquired from the fiber-optic gauge agreed well with the electronic gauges.

Cidra's fiber-optics technology is based on Bragg gratings that are permanently etched into the light-guiding core of the fiber. Cidra says that, because the gratings are integrated into the fiber and provide a narrow-band wavelength reflection, the sensors can be conveniently multiplexed in a fiber-optic network.

Cidra explains that the benefit of fiber-optic measurements include:

- Electrically passive, no downhole electronics.

- High temperature operations.

- Multipoint sensing capabilities.

- Immunity to electromagnetic and radio frequency interference.

- Low profile sensors.

- Safety.

In its fiber-optic systems, Cidra includes both a Bragg grating for measuring point values and a fiber for distributed temperature sensing along the fiber length.

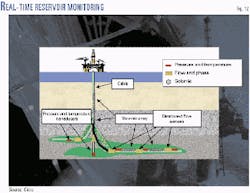

Tor Kragas, Cidra manager of reservoir applications, says the resolution of the current pressure gauge is 1.5 psi, a drift of less than 1 psi/year, and a resolution of 0.1 psi. The next generation due out in mid-2001 will have a 0.035 psi resolution.

Flow and phase fraction are other parameters that can be measured. Kragas says that in flow loop tests the flowmeters have demonstrated accuracy of ±5%, for both flow rate and phase fraction over the full range, 0-100% water cut. In addition to higher reliability, he indicates no internal restriction or Venturi is required for the measurement, allowing them to be full-bore.

In late 2000, Cidra installed a fiber-optic flow sensor in a Gulf of Mexico well.

Cidra also is developing optical based seismic sensors developed for downhole deployment, either behind casing or in the annulus.

Fig. 12 illustrates Cidras real time measuring concept for pressure, temperature, seismic and distributed flow.

Another type of fiber-optic device is being tested by Litton Guidance & Control Systems. It bases the system on a Mach-Zehnder fiber-optic electrical-to-optical converter. Litton says its three component (3C) device is a passive component that transforms an electrical output of a standard geophone into an optical signal. The optical characteristics of the converter are identical to fiber-optic hydrophones (OGJ, Mar. 27, 2000, p. 80).

The 3C device underwent testing in a Chevron Corp. Kern River, Calif., well in February 2001.