Researchers test mud formulas for Turkey's Dadas shale

Mustafa Haken Ozyurtkan

Istanbul Technical University

Istanbul

Two water-based mud (WBM) and one potassium-based mud (PBM) drilling fluid systems emerged as alternatives to non-aqueous based fluids (NAFs) in testing at the Silurian Dadas shale of southeast Turkey.

Laboratory results show WBM and PBM drilling fluids can be deployed for shales elsewhere having properties similar to the Silurian Dadas. These include the Vaca Muerta shale in Argentina and three US plays: the Eagle Ford and Barnett in Texas, and the Niobrara in Colorado.

Silurian Dadas operators initially considered NAFs, but their use poses environmental issues and is expensive. Operators instead sought customized alternate drilling fluids involving a combined water-based mud and salt-based mud.

Turkish National Oil Co. and Viking Services Co. provided shale samples for laboratory testing of three different mud systems.

Researchers studied the systems for rheology and water-loss properties in temperatures up to 250° F.

Drilling-fluid selection depends on a specific shale play's morphology and lithology, drilling requirements, and other reservoir-specific variables.

Unconventional natural gas shale formations vary considerably, especially regarding well bottom-hole temperature (BHT). NAFs offer good shale stabilization, lubricity, and contamination tolerance. But water-based muds (WBM) commonly offer more options at lower cost. WBM is more sensitive than NAFs to changes in temperature, salinity, pH, and contaminants.

A shale's reactive clay content and high BHT is crucial to its WBM design. PBM can be modified more easily than WBM to handle reactive clays and BHT. Operators use PBM to limit chemical modifications in shale formations.

Different clays offer different mud characteristics. Potassium ions fit closer into a clay lattice structure then do calcium ions. In the presence of montmorillonite, potassium replaces sodium and calcium to produce a stable, less hydrating structure.

Potassium substitutes for exchangeable impurities in the structure when illites are present. Potassium cations stabilize shales containing a large percentage of illite or illite-smectite layer combinations.

If the potassium level drops, clays and shales can hydrate, leading to borehole instability and mud loss problems.

A well-known PBM is potassium chloride mud (KCl), developed to provide wellbore stability and reduce cuttings dispersion. KCl used in water-sensitive formations provides low-formation damage and high-return permeability. A low-polymer concentration allows cuttings dispersion, resulting in increased viscosity.

Siluarian Dadas shale

The Silurian Dadas shale covers an estimated 480,000 acres in southeast Turkey. Latest assessments show the shale holding a potential 110 million bbl of oil (OGJ, July 1, 2013, p. 46).

The Dadas formation is deltaic. Sandstone and shale are found in outcrop in the Dadas and Zenala areas of North Diyarbakir and Mardin High. The formation's age ranges from Late Silurian to Early Devonian.

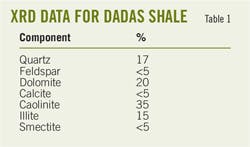

Table 1 shows X-ray diffraction (XRD) analysis of Dadas shale cuttings and core samples. Dadas shale consists of clay, dolomite, and quartz. The clay is almost exclusively caolinite and illite.

Potassium replaces sodium in illitic clay's lattice structure, making it less prone to swelling than in smectite clays.

XRD analysis showed the feasibility of WBM and PBM formulas for Dadas shale. Researchers added thinners and deflocculants to control drilling-fluid water loss.

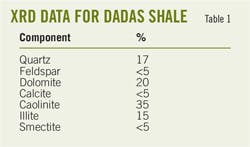

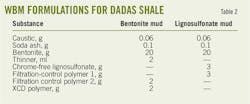

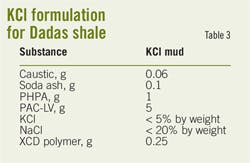

Table 2 shows WBMs thermal stability. KCl mud was designed to handle contamination caused by the shale play (Table 3).

The entry of solids and fluids from the formation into the drilling mud contaminates it. Shale as a contaminant was studied to determine how its entry might deteriorate key properties of specific drilling fluids.

Researchers ground shale samples into particles smaller than 75 microns. They added 30 g of particles to the drilling fluids being tested.

Each sample of contaminated and uncontaminated mud stood for 16 hrs at four different temperatures: 80°, 150°, 200°, and 250° F.

A rotational viscometer determined rheological properties. Researchers used a filter press to measure filtration properties at 80° F. under 100 psi and used a high-temperature, high-pressure filter press for tests at under 100 psi pressure difference, 200 psi with back-pressure applied, and 300 psi. The filter presses were API certified.

Testers also noted mud-cake thickness and the pH of mud and filtrate. Researchers tracked conformance with API's Recommended Practice RP13 throughout the study. Each experiment was repeated at least three times.

Shale contamination

Contamination from the shale itself caused an increase in the viscometer and rheometer readings, indicating an increase in the fluid's viscosity. Dial readings were taken at six different rpm: 600, 300, 200, 100, 6, and 3.

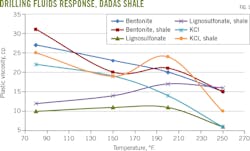

Fig. 1 shows plastic viscosity, contamination, and temperature variables of the three mud systems. Plastic viscosity values changed slightly with higher temperature.

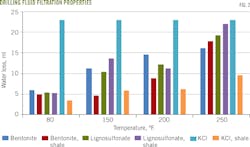

Fluid-loss properties varied with contamination and temperature (Fig. 2). Results are shown at room temperature for the bentonite mud. Bentonite's rheology stabilized at high temperature in spite of clay contamination.

Contamination and increased temperature caused a slight increase of water loss up to 200° F., and water loss rates increased more above 200° F.

Filtration values were 15 ml or less (API standards require filtration of less than 15 ml) even in different temperatures. Bentonite samples tolerated shale entry up to 250° F.

Shale contamination caused a slight increase at room temperature in dial reading and plastic viscosity values for lignosulfonate mud samples.

The plastic viscosity of the uncontaminated lignosulfonate mud samples decreased with higher temperature (Fig. 2). The lignosulfonate mud sample's viscosity, however, improved and did not decrease even at higher temperatures. Results revealed that the developed lignosulfonate mud samples' rheology was unaffected by shale contamination.

Contamination and increased temperature caused a slight increase in water loss up to 200° F. Water loss rates increased at 250° F. Filtration values were below 15 ml up to 200° F. Filtration values equaled 22 ml at 250° F. Although this value is above the API recommendation, it is still acceptable for field application.

Lignosulfonate mud samples also tolerated shale entry without measured changes in rheological and filtration properties. KCl mud's rheological properties were similar to bentonite mud. Shale contamination increased dial readings and caused higher plastic viscosity values for KCl mud samples at room temperature.

Plastic viscosity values measured more than 19 cp up to 200° F., but then decreased. Even so, they remained higher than those of the uncontaminated mud sample.

KCl mud was designed to provide good filtration properties in case of contamination. Fig. 2 shows that uncontaminated KCl mud's filtration was too high (>50 ml). When contaminated, however, filtrate volumes were very low even at higher temperatures. The water-loss values were all below 10 ml, in adherence with the API-recommended sub-15 ml recommendation.

Bibliography

Alsharhan, A.S. and Nairn, A.E.M., "Sedimentary basins and petroleum geology of the Middle East," Elsevier Science, Dec. 11, 1997.

Arthur, J.D., Bohm, B., and Cornue, D., "Environmental Considerations of Modern Shale Gas Development," Society of Petroleum Engineers Annual Technical Conference and Exhibition, New Orleans, Oct. 4-7, 2009.

Aydemir, A. "Potential Shale Gas Resources in Turkey: Evaluating Ecological Prospects, Geochemical Properties, Surface Access and Infrastructure," Global Shale Gas Summit, Warsaw, Sept. 2, 2010.

Aytac, E., "Lower Paleozoic Oil Potential of Southeast Turkey, Districts 10 & 11," The Petform Panels, Ankara, Jan. 11, 2010.

Darley, H.C.H. and Gray, G.R., "Composition and Properties of Drilling and Completion Fluids," Gulf Professional Publishing Co., Houston, 1988.

Ozyurtkan, M.H., "Customization of Aqueous Based Muds for Unconventional Shale Reservoirs," South American Congress on Rock Mechanics, Buenos Aires, Sept. 15-18, 2015.

Passey, Q.R., Bohacs, K.M., Esch, W.L., Klimentidis, R., and Sinha, S., "From Oil-Prone Source Rock to Gas-Producing Shale Reservoir-Geologic and Petrophysical Characterization of Shale-Gas Reservoirs," International Oil and Gas Conference and Exhibition, Beijing, July 28, 2010.

Weijermars, R., "Jumps in Proved Unconventional Gas Reserves Present Challenges to Reserves Auditing," SPE Economics and Management Journal, Vol. 4, No. 3, pp. 131-146, July 2012.

The author

Mustafa Hakan Ozyurtkan ([email protected]) is an assistant professor at Istanbul Technical University (ITU). He received his BS (2003) in petroleum engineering from ITU. He also earned MS degrees (2006) in petroleum engineering and energy science from ITU, where he became a research and teaching assistant in 2005. He studied wellbore cement as a visiting scholar at Louisiana State University in Baton Rouge, La., in 2010, and received a PhD (2012) from ITU.