New approach predicts volume mixing in long, multiproduct pipeline

Liang Yongtu

China University of Petroleum

Beijing

Xiaolei Guo

Oil and Gas Pipeline Control Center

Beijing

Combining the classical Austin-Palfrey formula with field data creates a new formula capable of predicting the amount of mixed-product volume arriving at each terminal of a long, multiproduct pipeline crossing varied terrain.

The new formula considers the structure and terrain of the pipeline, the characteristics of the mixed oil products in its pumping stations, and the distribution of the products along its length.

Background

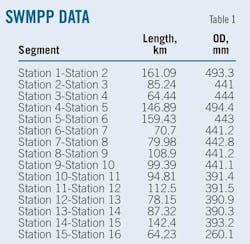

The 1,691-km trunkline of China's Southwest Multi-Product Pipeline (SWMPP) has 16 pump stations. The topography of the first half is gentle, while subsequent sections become rugged. OD along the trunkline varies in correspondence with design throughput as it changes along different sections of the pipeline.1 Table 1 shows the different diameters along the pipeline from the initial station to the final terminal.

The operation cost of batch transportation on the multiproduct pipeline increases in accordance with contamination, which is unavoidable at the interface between different batches. A relatively precise estimation of mixing volume, the amount of product that has become cross-contaminated, influences its disposition in the terminal station.

The Austin-Palfrey formula can only be applied to a horizontal pipe having the same OD for its entire length, considering flow characteristics and growth rules of mixed oil products.2 It became necessary, therefore, to find useful information from the field data to obtain a contamination product formula for the SWMPP.

This article establishes a new formula that includes such influential factors as terrain and structure of the pipeline, initial mixing volume, variation of throughput, changes in OD, characteristics of mixed oil products in its pumping stations, and distribution of products along its length.

SWMPP is divided into 15 sections. Applying the Austin-Palfrey formula to each of the 15 sections yields a relatively precise mixing volume calculation for the terminal station.

Contamination formula

Field data show each pipeline segment operating under conditions such that the Reynolds number is larger than the critical Reynolds number, requiring introduction of a coefficient to the Austin formula suitable to the SWMPP in the smooth area.

Equation 1 shows the Austin-Palfrey formula to be used when the Reynolds number is larger than the critical Reynolds number.

SWMPP has several subtransmission points, causing the flow rate to vary along the pipeline. OD of different segments varies according to the designed flow rate. Using the change point of flow rate or the diameter change point allows division of the pipeline into segments.

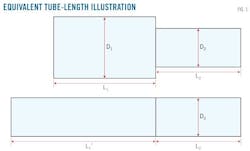

Instead of changing the diameter and flow rate of each pipeline segment, this article uses the equivalent tube-length method.3 An example illustrates this method using a two-segment pipeline (Fig. 1). The length and OD measure L1 and D1, respectively. Flow rate = Q1, Reynolds number = Re1, and length of contamination = C1. The converted length and OD are L2 and D2. The flow rate is Q2 and Reynolds number Re2.

When Reynolds number exceeds the critical Reynolds number, using the equivalent tube-length method and the Austin-Palfrey formula, Equations 2-4 calculate the length of contamination at the end point of segment C2.

Though volumes of initially contaminated product and midway downloaded contaminated product are small, they still affect calculation of the mixing volume at the end point of each segment. Initial contaminated product is introduced at the initial station. Converting the initial contaminated product volume into equivalent tube length precedes adding it to the length of the first pipeline segment.

SWMPP has 12 subtransmission points. Each subtransmission point is likely to download contaminated product. Subtracting midway downloaded mixed oil product is subtracted from the mixed oil products that arrive at the end point precedes converting the remaining mixed oil products volume into equivalent tube length and adding this equivalent tube length to the length of the pipe segment.

The volume of cross-mixed products caused by pumping stations varies for every pipeline and is treated as a constant here to simplify calculation. Doing so does not affect results of the contaminated product formula regression.

Analysis and calculation yield Equation 5, a modified contamination formula with the form of Austin-Palfrey formula under the condition that the Reynolds number is larger than the critical Reynolds number.

Regression analysis of SWMPP's field data provides the coefficient of every section and contamination calculation formulae meeting the characteristics of the products pipeline.

Displaying 1/3 Page1, 2, 3Next>

View Article as Single page