P. 3 ~ Continued - New approach predicts volume mixing in long, multiproduct pipeline

View Article as Single page

Terrain effects

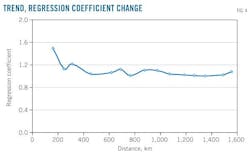

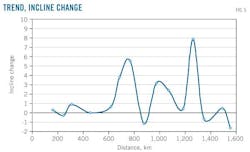

Verifying the initial assumption that the terrain and structure of the pipeline should be recognized as factors requires calculating the relationship between the regression coefficient and the incline of each pipeline segment. Figs. 4 and 5 show the regression coefficients and the inclines, respectively.

The change in the regression coefficients is consistent with that of pipeline incline in the first half of the pipeline, but the regression coefficients in the second half scarcely change.

Terrain has a smaller effect on mixing volume as it travels along the pipe. At the beginning of transportation the mixing volume is proportionally larger. The axial concentration gradient becomes flatter, however, and the diffusion coefficient smaller as the mixing zone is transported along the pipeline.4

Researchers have already proven that when the Reynolds number is larger than the critical Reynolds number, the influence of incline upon the mixing volume calculation can be ignored.5 Their conclusion does not contradict this article.

Though the change in the regression coefficient is consistent with that of incline, it does not prove disproportionate under this condition, making the influence of topography on mixing volume calculation minimal. This influence should, however, be considered when calculating the mixed oil products volume of a variable-diameter products pipeline to improve accuracy in predicting the mixing volume expected to arrive at the terminal station.

Application

According to the results of the developed batch-schedule software, including average flow and distribution of the mixing volume along the pipeline, the new formula allows prediction of product mixing.

This computing method is suited to any pipeline having a variable diameter under all kinds of operating conditions, as shown in the following examples (assuming known average flow and initial contamination for each section).

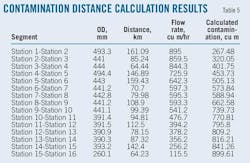

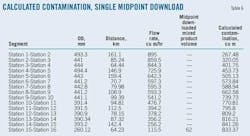

Table 5 shows in the calculation results of contaminated volumes reaching each station based on an initial mixed volume of 45 cu m and no mixed oil being introduced along the pipeline.

Table 6 shows the calculation results of contaminated volumes reaching each station based on an initial mixed volume is 45 cu m, a downloaded mixed volume in Segment 15-16 of 62 cu m, and no mixed oil product downloaded in the other stations.

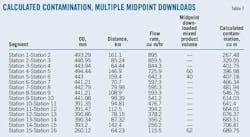

Table 7 shows the calculation results of contaminated volumes reaching each station based on an initial mixed volume 45 cu m, downloaded mixed volumes in Segment 4-5 of 60 cu m, in the Segment 5-6 of 40 cu m, and in Segment 15-16 of 62 cu m. No additional mixed oil product downloading occurs at the other stations.

The calculations in Tables 5, 6, and 7 show that the higher the volume of mixed oil products downloaded at each station, the smaller the mixed volume that arrives at the terminal station under the same flow conditions.

References

1. Dai, F., and Hu, X., "The Contamination calculation Formula for the Southwest Multi-product Pipeline," Oil & Gas Storage and Transportation, Vol. 28 (2009), No. 2, pp. 40-42.

2. Deng, S., and Pu, J., "The comparison between 1-d model and two-dimensional model of the multi-product pipeline," Oil & Gas Storage and Transportation, Vol. 16 (1997), No. 1, pp. 16-18.

3. Chen, Q., "Calculations on the Mixing Volume of Products Pipeline with Variable Diameter Pipes," Oil & Gas Storage and Transportation, Vol. 18 (1999), No. 1, pp. 7-8.

4. Yang, X., and Zhang, G., "Design and Management of Oil Products Pipeline," Beijng: China University of Petroleum Press, 2005.

5. Kang, Z., and Gong, J., "The Study on the Contamination of Products Pipeline," Oil & Gas Storage and Transportation, Vol. 21 (2002), No. 5, pp. 1-4.

The authors

Displaying 3/3

View Article as Single page

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com