P. 4 ~ Continued - Amine cleaning technology tests successfully in Aramco plants

Displaying 4/6

View Article as Single page

To demonstrate the effect of the contamination level of Uthmaniyah DGA solution, we performed a standard foaming test, which showed a dramatic improvement in system potential to create foam after use of the Amine Shield unit (Fig. 3).

| Shown are the foam heights of Uthmaniyah's high-pressure DGA system solution before and after the Amine Shield test—photo on left is System DGA, May 19, 2010; one on right is System DGA, May 31, 2010 (Fig. 3). |

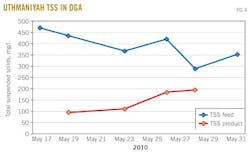

As can be seen from Fig. 4, the suspended-solids content in the unit was reduced to 350 mg/l. from 470 mg/l., about a 27% reduction.

In addition, the removal rate across the MPR unit ranged 30-80%. This variation was due to several factors:

• During the Uthmaniyah plant DGA trial, the required hot water for unit regeneration was unavailable. The hot condensate temperature at the gas plant fell to 55° C. As a consequence the efficiency per run declined, i.e., more solids broke through and the curve increased instead of decreased.

• Amine samples have been collected at different times after unit regeneration. The removal rate normally starts high after the Amine Shield unit regeneration and begins to decline until the unit is switched to regeneration mode.

• The Amine Shield unit performance is proportional to contamination level in the system and removal rate increases with an increasing solid and hydrocarbon content.

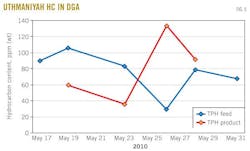

The hydrocarbon-removal rate across the Amine Shield slipstream unit has been 40-60%. This could not be maintained throughout the Uthmaniyah plant's trial (Fig. 9). This observation is attributed to the following:

• The use of relatively warm water (122-130° F.), which caused the HCX unit media to foul; hence its performance started to deteriorate. The HCX requires hot water at 175-195° F. for efficient regeneration and complete removal of hydrocarbon.

• Neither Uthmaniyah nor Hawiyah labs have the capability to measure the hydrocarbon content in DGA. The test progress was therefore monitored through the daily suspended-solids analyses, which have shown good performance. In addition, during the Uthmaniyah plant trial, test-sample appearance improved.

• The relatively low hydrocarbon content of the DGA solution in the system during the test. Both HCX and SSX performances are demonstrated at high contamination level (typically higher than 200-400 ppm wt solids and hydrocarbon).

Test at Hawiyah

The test at Hawiyah's GT-3 started on June 12, 2010, and was completed on Aug. 1, 2010. During cleaning, a slipstream of DGA from upstream of the precoat filter had been passing through the Amine Shield unit. The cleaned DGA was returned to the flash drum through the outlet piping from the DGA sump downstream the sump filters.

During regeneration, the unit used hot water from the 330-psig steam condensate to the precoat filter line. The waste stream was sent to the wet blowdown system through a piping connection from the unit to the blowdown line from the DGA flash drum.

Displaying 4/6

View Article as Single page