P. 5 ~ Continued - Amine cleaning technology tests successfully in Aramco plants

During the Hawiyah trial, the Amine Shield slipstream unit was not running continuously and was shut down several times due to the following:

• GT-3 unit being shut down three times due to process upsets.

• Excessive regeneration frequency of the unit took place in the beginning. It was discovered later that the HCX and SSX media fouled because of not having the required hot water temperature for regeneration at Uthmaniyah high-pressure DGA test.

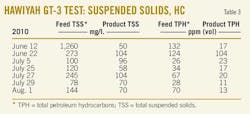

• HCX and SSX media replacement. Samples have been collected during the test period; Table 3 shows analyses results. Figs. 6 and 7 show the quality improvement of the amine solution dur-ing the test at GT-3.

Shown are DGA samples from the system, precoat, and Amine Shield (Fig. 6).

During the trial at GT-3, the existing precoat filter media were cleaned and new filter aid was added. The precoat filter performance declined rapidly and started to show low performance. The outlet from the precoat filter looked almost like the inlet, and there was a clear difference when compared with the outlet of MPR's Amine Shield unit.

Solids; HC content

At the Hawiyah trial, the results showed a marked decrease in the suspended-solids content of the DGA system, to 144 mg/l. from 1,260 mg/l., about a 90% reduction (Fig. 8). In addition, the removal rate across the MPR unit ranged 10-95%. Similar to Uthmaniyah trial, samples had been collected at different times after unit regeneration. The removal rate normally starts high after the Amine Shield unit regeneration and begins to decline until the unit is switched to regeneration mode.

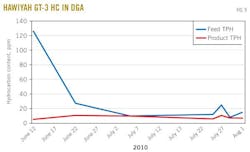

Fig. 9 shows the hydrocarbon content of Hawiyah's GT-3 DGA solution. Although the graph shows much hydrocarbon removal at the beginning of the test, the unit had to be regenerated more frequently and could not sustain its good performance.

MPR operators had to shut down the unit and inspect the filter media where the HCX resin and SSX filter elements were replaced due to fouling. MPR analyses concluded that the use of warm water (about 130° F.) at the Uthmaniyah trial was the main cause of resin fouling, since the HCX media require higher temperature (175-195° F.) for good regeneration.

After replacement of the SSX and HCX media, the performance of the HCX improved and a removal rate of 50-80% was achieved across the unit during the last week of the test. Because the hydrocarbon analyses could not be performed on site by the plant laboratory, the results do not represent the actual test samples because some of the hydrocarbon might have evaporated during shipment and storage.

Another factor was that the initial hydrocarbon level in the DGA was not very high, which affects the accuracy of the measurement.

Displaying 5/6 1, 2, 3, 4, 5, 6Next>View Article as Single page