Amine cleaning technology tests successfully in Aramco plants

Saud H. Al-Mudaibegh

Saudi Aramco

Dhahran

| Based on a presentation to 19th Annual Technical Conference of the GCC Chapter of the Gas Processors Association, May 4, 2011, Kuwait. |

Testing of an amine-regeneration technology at two natural gas processing plants owned and operated by Saudi Aramco revealed an improvement in amine performance and quality.

Performance of an amine solution in gas plants is reduced mainly by accumulation of such contaminants as suspended solids, hydrocarbon liquids, and degradation products.

Results of tests of the Amine Shield slipstream unit in the Aramco plants showed that suspended solids-removal rate across the unit reached up to 90%. In addition, the total amine system solids content dropped by more than 80% at one plant. Such treatment will reduce contaminants and hence decrease problems related to foaming and fouling in the system.

The Amine Shield slipstream technology, developed by MPR Services Inc., Dickinson, Tex., employs a multifunctional unit that removes solids, hydrocarbons, and heat-stable salts from an amine system.

Several amine-treating units at Saudi Aramco's gas plants experience amine losses, poor quality amine, and foaming. Antifoam is injected continuously at many units, and the current conventional solution filtration systems (precoat filter) are inefficient.

The test was implemented in the Hawiyah and Uthmaniyah gas plants

Amine losses

Gas treating units that use amine and glycol solvents encounter a variety of operational problems. Most are caused or aggravated by the presence of such contaminants as degradation products, solids, and hydrocarbon that accumulate in the system.

These contaminants are produced within the system by corrosion or erosion or introduced into the system with the feed gas. Contaminated amine or glycol solutions degrade solvent performance and lead to foaming, solvent losses, and equipment fouling.

Overcoming these operational issues requires several measures. These include antifoam injection, fresh solvent addition, and installation of conventional mechanical solution filters on a slipstream for continuous cleaning. In many systems, these methods are ineffective and do not represent the optimum solution and the solvent remains contaminated.

Amine losses are generally categorized by the following:

• Entrainment. This is physical carryover that is largely related to column hydraulics, foaming, and contaminants in amine solvent.

• Mechanical. These losses result from equipment and piping leaks, filter changeout, and drainage.

• Vaporization. These losses result from the equilibrium vapor pressure of the amine in the solution varying with operating conditions. Normally the actual losses due to vaporization are less than equilibrium losses because amine treating units operate lower than full equilibrium.

• Degradation. Some amines, specifically diglycol amine (DGA) go through different reactions with different components in a sour-gas stream, such as CO2 and COS, and as a result produce degraded products.

• Solubility in hydrocarbon liquid (in liquid-treating units). Such losses resemble vaporization in which amines establish equilibrium with the liquid hydrocarbon.

Typical losses in amine treating units range 0.5-3.0 lb/MMscf of treated gas. Saudi Aramco's gas plants consume more than 900,000 gal/year of DGA as solution make-up to compensate for losses.

It is believed that most of these losses result from degradation and poor amine quality. Different surveys have revealed that DGA and triethylene glycol (TEG) systems with high contamination levels experience much higher losses.

Like many other gas-treating units within Saudi Aramco, the Uthmaniyah gas plant high-pressure and gas treating unit No. 3 (GT-3) has experienced low-quality amine and several process upsets. The presence of inefficient feed-gas filtration-separation and the low efficiency of the conventional DGA solution filter result in an accumulation of solids and hydrocarbon in the amine-solution loop. Maintaining pure amine improves solvent performance and minimizes process upsets and amine losses.

The Amine Shield slipstream technology is based on a proprietary material for suspended-solids removal and special resins for hydrocarbon removal to achieve a high removal rate. The technology is a regenerative process in which the unit is continuously regenerated with hot water.

The Uthmaniyah gas plant (UGP) high-pressure DGA gas-treating unit processes about 600 MMscfd of sour gas at about 980 psig. About 280,000 gal inventory of DGA treating solvent is maintained clean through use of a conventional slipstream mechanical (precoat) filter that processes 10-15% of the 4,000 gpm circulation rate.

A filter aid material is continuously added to the filter element to achieve the removal. In reality the precoat filter, unless it's opened, cleaned, and a new filter aid added, will be saturated within few days and lose its functionality in removing dirt and suspended solids from the system. The HPDGA unit at UGP experiences high contamination levels, and the potential for foaming is very high. Antifoam is therefore added continuously.

Similarly, the HGP's Gas Treat-3 unit processes about 500 MMscfd of sour gas at about 550 psig. The DGA system contains around 130,000 gal of DGA solution, which is maintained clean through use of a conventional slipstream mechanical (precoat) filter that processes 10-15% of the 2,100 gpm circulated DGA. A filter-aid material is continuously added to the filter element to achieve removal.

In reality the precoat filter will be saturated and within few days will lose its functionality in removing suspended solids from the system unless it is opened and cleaned and a new filter aid added. Like the HPDGA unit at UGP, HGP's GT-3 experiences high contamination levels with a high potential for foaming. Antifoam is therefore added continuously.

Amine Shield slipstream

The MPR technology, embodied into a mobile skid, contains a suspended-solids removal unit (SSX), hydrocarbon-removal unit (HCX), and heat-stable salt removal (HSSX; Fig. 1). The unit is equipped with hoses to connect the mobile skid to:

• The amine system to feed the unit.

• The waste system to dispose of impurities removed during regeneration.

• The hot condensate system to supply the unit with hot regeneration water.

It is also equipped with a computerized system to monitor, adjust, and control process variables. Upstream of the unit's inlet is a pressure-reduction valve to let down the process fluid pressure to the unit's operating pressure, which is typically around 150 psig.

• Suspended-solids removal unit. The SSX vessel contains proprietary filter media to remove suspended solids of different sizes down to submicron level. It has more than 19 times greater capacity for retaining solids than the equivalent volume of a cartridge filter and can be regenerated on site.

• Hydrocarbon-removal unit. The HCX vessel contains a proprietary material (resin) available exclusively from MPR. It removes hydrocarbons including diesel, fluid catalytic cracking gasoline, gas oils, paraffins, BTEX (benzene, toluene, ethylbenzene, and xylene), and various other petroleum intermediates from aqueous gas-treating solutions The HCX media capacity is more than 10 times greater than the equivalent volume of activated carbon for retaining hydrocarbons.

The skid-mounted unit takes a slipstream from the DGA system and passes it through the SSX media, which trap suspended solids. Then the stream continues to the HCX unit to remove hydrocarbons, after which the clean stream is returned to the main amine system.

When the unit is exhausted, it is switched to the regeneration mode, which introduces hot water to remove the solids and hydrocarbon waste from the SSX and HCX. The unit is operated until the amine system's inventory is cleaned to a target value (typically less than 100 mg/l. suspended solids and 100 ppm vol hydrocarbon).

Methodology

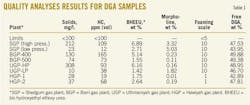

DGA samples from units with operational concerns were sent to MPR Inc. for suspended solids, hydrocarbons, and other common DGA contaminant analyses. Because of the numerous DGA units within Saudi Aramco, the number of samples was limited. Table 1 shows the results.

Typically recommended suspended-solids and hydrocarbon content for gas-treating units are, respectively, 100 mg/l. and 100 ppm (vol). Based on the analyses, the mobile unit was installed at Uthmaniyah plant's high-pressure DGA. Later, Hawiyah plant management highlighted a concern in the DGA solution quality at GT-3 and showed its interest to have a field trial at HGP GT-3. They shared the expenses of the technology test.

Therefore, this was an opportunity to confirm technology benefits at another facility and resolve a current operational issue.

The Amine Shield slipstream unit was tested at the two locations. Samples of DGA upstream of the Amine Shield (system-feed), downstream of the unit, and downstream of the existing precoat filters were collected throughout the test and sent for analyses. Additional samples were also sent to gas plant labs and research and development to monitor the unit's performance and compare it with MPR results.

The gas plants' lab results showed discrepancies and scatter, which made them difficult to utilize. These results have shown, however, a large reduction in suspended solids content across the Amine Shield unit.

Uthmaniyah HPDGA unit

Testing of the Amine Shield slipstream unit started at the Uthmaniyah high-pressure DGA system on May 17, 2010, and was completed on May 31, 2010. During cleaning, a slipstream of DGA from upstream of the precoat filter downstream of the precoat filter pumps has been passing through the Amine Shield unit.

The cleaned DGA was returned to the flash drum through the outlet piping from the DGA sump downstream of the sump filters. During regeneration, the unit used hot water from the 330-psig steam condensate to the precoat filter line. The waste stream was sent to the wet blowdown system through a piping connection from the unit to the 2-in. blowdown line from the DGA stripper reflux drum.

Samples collected during the test period were sent to MPR laboratory in the US for suspended solids, hydrocarbon, and composition analyses. Table 2 shows the suspended solids and hydrocarbon analyses results.

The performance of MPR's Amine Shield slipstream unit has been good. There was significant improvement in amine quality across the Amine Shield unit when compared with the exist-ing precoat filter. Fig. 2 shows the sustained technology performance throughout the test compared with precoat filter.

To demonstrate the effect of the contamination level of Uthmaniyah DGA solution, we performed a standard foaming test, which showed a dramatic improvement in system potential to create foam after use of the Amine Shield unit (Fig. 3).

| Shown are the foam heights of Uthmaniyah's high-pressure DGA system solution before and after the Amine Shield test—photo on left is System DGA, May 19, 2010; one on right is System DGA, May 31, 2010 (Fig. 3). |

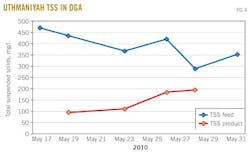

As can be seen from Fig. 4, the suspended-solids content in the unit was reduced to 350 mg/l. from 470 mg/l., about a 27% reduction.

In addition, the removal rate across the MPR unit ranged 30-80%. This variation was due to several factors:

• During the Uthmaniyah plant DGA trial, the required hot water for unit regeneration was unavailable. The hot condensate temperature at the gas plant fell to 55° C. As a consequence the efficiency per run declined, i.e., more solids broke through and the curve increased instead of decreased.

• Amine samples have been collected at different times after unit regeneration. The removal rate normally starts high after the Amine Shield unit regeneration and begins to decline until the unit is switched to regeneration mode.

• The Amine Shield unit performance is proportional to contamination level in the system and removal rate increases with an increasing solid and hydrocarbon content.

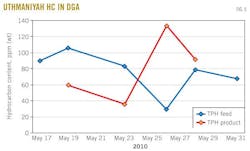

The hydrocarbon-removal rate across the Amine Shield slipstream unit has been 40-60%. This could not be maintained throughout the Uthmaniyah plant's trial (Fig. 9). This observation is attributed to the following:

• The use of relatively warm water (122-130° F.), which caused the HCX unit media to foul; hence its performance started to deteriorate. The HCX requires hot water at 175-195° F. for efficient regeneration and complete removal of hydrocarbon.

• Neither Uthmaniyah nor Hawiyah labs have the capability to measure the hydrocarbon content in DGA. The test progress was therefore monitored through the daily suspended-solids analyses, which have shown good performance. In addition, during the Uthmaniyah plant trial, test-sample appearance improved.

• The relatively low hydrocarbon content of the DGA solution in the system during the test. Both HCX and SSX performances are demonstrated at high contamination level (typically higher than 200-400 ppm wt solids and hydrocarbon).

Test at Hawiyah

The test at Hawiyah's GT-3 started on June 12, 2010, and was completed on Aug. 1, 2010. During cleaning, a slipstream of DGA from upstream of the precoat filter had been passing through the Amine Shield unit. The cleaned DGA was returned to the flash drum through the outlet piping from the DGA sump downstream the sump filters.

During regeneration, the unit used hot water from the 330-psig steam condensate to the precoat filter line. The waste stream was sent to the wet blowdown system through a piping connection from the unit to the blowdown line from the DGA flash drum.

During the Hawiyah trial, the Amine Shield slipstream unit was not running continuously and was shut down several times due to the following:

• GT-3 unit being shut down three times due to process upsets.

• Excessive regeneration frequency of the unit took place in the beginning. It was discovered later that the HCX and SSX media fouled because of not having the required hot water temperature for regeneration at Uthmaniyah high-pressure DGA test.

• HCX and SSX media replacement. Samples have been collected during the test period; Table 3 shows analyses results. Figs. 6 and 7 show the quality improvement of the amine solution dur-ing the test at GT-3.

Shown are DGA samples from the system, precoat, and Amine Shield (Fig. 6).

During the trial at GT-3, the existing precoat filter media were cleaned and new filter aid was added. The precoat filter performance declined rapidly and started to show low performance. The outlet from the precoat filter looked almost like the inlet, and there was a clear difference when compared with the outlet of MPR's Amine Shield unit.

Solids; HC content

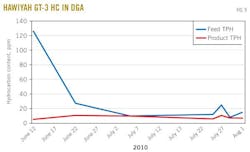

At the Hawiyah trial, the results showed a marked decrease in the suspended-solids content of the DGA system, to 144 mg/l. from 1,260 mg/l., about a 90% reduction (Fig. 8). In addition, the removal rate across the MPR unit ranged 10-95%. Similar to Uthmaniyah trial, samples had been collected at different times after unit regeneration. The removal rate normally starts high after the Amine Shield unit regeneration and begins to decline until the unit is switched to regeneration mode.

Fig. 9 shows the hydrocarbon content of Hawiyah's GT-3 DGA solution. Although the graph shows much hydrocarbon removal at the beginning of the test, the unit had to be regenerated more frequently and could not sustain its good performance.

MPR operators had to shut down the unit and inspect the filter media where the HCX resin and SSX filter elements were replaced due to fouling. MPR analyses concluded that the use of warm water (about 130° F.) at the Uthmaniyah trial was the main cause of resin fouling, since the HCX media require higher temperature (175-195° F.) for good regeneration.

After replacement of the SSX and HCX media, the performance of the HCX improved and a removal rate of 50-80% was achieved across the unit during the last week of the test. Because the hydrocarbon analyses could not be performed on site by the plant laboratory, the results do not represent the actual test samples because some of the hydrocarbon might have evaporated during shipment and storage.

Another factor was that the initial hydrocarbon level in the DGA was not very high, which affects the accuracy of the measurement.

Results obtained from Uthmaniyah and Hawiyah field tests of the Amine Shield slipstream unit technology led to the following conclusions:

• The Amine Shield slipstream unit has shown excellent performance in cleaning the DGA solution. Although the unit's processing capacity was limited to 35-70 gpm, which represents less than 1-3% of Uthmaniyah's high-pressure DGA and Hawiyah's GT-3 circulation rates, it resulted in marked improvement in DGA quality in short period.

• Up to 95% removal rate of suspended solids could be achieved across the Amine Shield slipstream unit.

• Up to 90% reduction in suspended-solids content in the amine system is achievable by the Amine Shield slipstream unit.

• Using hot water at 80-90° C. for unit regeneration is critical to ensure good performance of the Amine Shield slipstream unit.

• The current conventional filtration equipment (the precoat filter and carbon filters) for the DGA solution in gas plants is inefficient.

• Current amine analysis methods for suspended solids at gas plant laboratories are inaccurate and require revision and update.

• The Amine Shield slipstream unit capability is better demonstrated at high contamination levels (more than 100 mg/l. TSS and 100 ppm vol hydrocarbon)

• The use of this technology will reduce the contamination levels in the amine-glycol system, which will help improve the solvent performance, minimize foaming and equipment fouling, and reduce solvent losses. Additionally, the long-term benefit of sustaining a clean system will minimize testing and inspection and equipment repairs.

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com