MaxCell® Enables Scalable Pathways Without Additional Conduit

Key Highlights

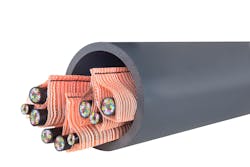

MaxCell’s flexible fabric innerduct allowed up to nine cables in a 4" conduit, tripling the capacity compared to traditional HDPE innerduct.

MaxCell’s lightweight and compact construction led to 2X faster installation than HDPE, lowering labor and material costs.

MaxCell offers an 81.24% reduction in carbon emissions compared to HDPE, aligning with the petrochemical plant’s sustainability goals.

When High-Bandwidth Connectivity is Essential

When a global oil company decided to build its first greenfield project in the U.S. in over 35 years, they chose a 1,400-acre location near the Gulf Coast for their greenfield build of a state-of-the-art petrochemical plant to produce fundamental chemical materials used in a variety of industries.

The massive industrial manufacturing facility included operations buildings, parking, shelters, water tanks, storage tanks, railroad operations to move freight to and from the facility, maintenance and repair services, emergency facilities and security operations. Connecting the structures and IoT enabled technologies across the facility was of utmost importance. Optical fiber played an integral part in providing reliable high-quality, high-bandwidth connectivity for a wide array of plant-wide applications and processes.

Challenges Around Network Infrastructure Design

The scale, scope and location of the project presented several challenges, including:

Massive facility size

Due to the number of associated structures and buildings, a fiber ring and redundancy ring were needed. This required 15 miles of fiber to be deployed.

Limited infrastructure space

The crowded refinery environment called for a solution that reduced the number of conduits required while preserving future space.

Risk of downtime

Unplanned downtime is costly in a petrochemical plant. The fiber cabling needed superior protection to minimize disruptions.

Tight project timelines

A fast, efficient field installation was required to get the plant up and running.

Proximity to waterways

The water table near the plant was close to ground surface, making installation a challenge.

Harsh ground conditions

The environment called for innerduct that was resistant to water, chemicals, petroleum and

temperature fluctuations.

MaxCell Fabric Innerduct Checked All the Boxes

After careful consideration to find a product that would meet reliability specifications, as well as one that could be easily installed in challenging environments, the flexible fabric innerduct system from MaxCell was chosen.

MaxCell is manufactured in the U.S.A. from internally processed polyester and nylon resins. Because the materials used in MaxCell are rated for 20+ years of use with less than a 15% reduction in strength, and the physical properties provide outstanding tenacity and toughness as well as abrasion, temperature, water and chemical resistance, it would help minimize downtime in the plant and limit the unexpected. The materials used in MaxCell have excellent resistance to fuels and ground chemicals which made it a perfect fit for this petrochemical manufacturing environment. Exposure to water, salt-water or mud do not affect the life expectancy of MaxCell which means this product outperforms standard HDPE innerduct in terms of response to heat or freezing temperatures.

Project Scope

Fiber Ring and Redundancy Ring

Fifteen miles (eight 4" conduits used)

Application

Three packs of 3" three-cell for nine pathways in each 4" conduit resulting in a total of 72 pathways

Fiber Placement

Six 288 fiber count cables in each conduit, leaving three pathways for future use in each conduit

MaxCell’s unique flexible fabric design allows it to conform to the shape of the cables placed within, which greatly reduces the wasted space associated with using rigid innerduct and enables higher cable density in a pathway. This solved the issue of having limited space for conduits in the crowded refinery environment. MaxCell offers maximum efficiency where space is limited and this was especially important in the cable runs to outlying buildings within the project.

The choice of MaxCell’s flexible fabric innerduct delivered overall cost-savings in two different ways:

The compact, light-weight construction lowered the freight and storage costs as compared to standard HDPE innerduct.

Installation is 2X faster than standard HDPE innerduct, resulting in reduced labor and material costs.

The MaxCell team provided product installation training for this project and because MaxCell was designed for easier and faster installation, it can cut conduit installation time in half and greatly increase cable installation speed. This allowed for a streamlined installation process that was completed on schedule and cost-effectively.

Most importantly, traditional construction in a 4" conduit allows only three cables to be placed. MaxCell triples the capacity, allowing up to nine cables to be placed in the 4" conduit, resulting in a 300% increase in cable density. MaxCell’s design preserves space for future bandwidth requirements, allowing for additional cables to be added in the future without costly downtime.

Reduced Carbon Emissions With MaxCell

Because this petrochemical plant is committed to protecting public safety, health and the environment, they are safe, responsible stewards of hydrocarbons and that commitment is integrated into the facility design and operating procedures.

MaxCell has a similar commitment to protecting the environment. For every million feet of single-cell MaxCell installed instead of HDPE innerduct, the resulting carbon savings are 644 metric tons CO2 equivalent. This is equivalent to the annual emissions from over 126 passenger vehicles on the road or over 72,000 gallons of gasoline consumed.

According to independent calculations formed on this product, there is an 81.24% carbon emissions reduction from using MaxCell versus HDPE innerduct.

Conclusion

This petrochemical plant project had unique and complex challenges including a high-risk cable damage environment, mission-critical fiber lines, and limited space for installation. The enhanced efficiency of MaxCell’s flexible fabric innerduct, along with its robust, long-term reliability, turned these challenges into opportunities.