New Zealand refinery lets service contract

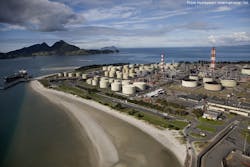

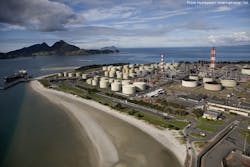

New Zealand Refining Co. Ltd. (NZRC) has let a 5-year contract to Honeywell Process Solutions (HPS), a division of Honeywell International Inc., to maintain and modernize control systems as part of a long-term program designed to improve operations and support technology innovation at NZRC’s 107,000-b/d Marsden Point refinery at Northland, about 160 km north of Auckland on the North Island’s east coast.

The service provider will deliver full lifecycle maintenance, support, and project delivery for the refinery’s control systems, as well as migrate the refinery to the most recent process control technology using Honeywell’s Experion Process Knowledge System (PKS), Honeywell said.

A value of the contract was not disclosed.

Project updates

The Marsden Point refinery, New Zealand’s only such facility, recently completed a series of initiatives to boost processing margins, including a modification to the hydrogen separation unit, a hydrocracker ammoniation project, and installation of a short residue transfer line from a high-vacuum unit to the butane deasphalting unit, NZRC said.

Owned by major shareholders BP New Zealand Holdings Ltd., Mobil Oil NZ Ltd., Z Energy Ltd., as well as additional private and institutional investors, the refiner also confirmed it remains on track to commission its Te Mahi Hou (TMH) expansion project at Marsden Point by mid to late November (OGJ Online, May 29, 2015).

Approved in February 2012 and initially named the Continuous Catalyst Regeneration (CCR) Platformer project (CCR), the TMH project aims to increase the refinery’s high-quality fuel production by replacing an existing semiregeneration platformer and enabling it to process increased volumes of a wider range of crudes more effectively and efficiently (OGJ Online, Mar. 4, 2014).

In its interim report for 2015, issued in late September, NZRC said TMH precommissioning activities already were under way.

NZRC also plans to pursue a series of smaller capital projects over the next 3-4 years specifically designed to enhance margins, said NZRC Chairman Simon Allen.

Further details regarding the future projects likely will be announced by yearend, Allen said.

Earlier in the year, NZRC completed a scheduled 3-week shutdown of the refinery for planned maintenance and catalyst regeneration at a crude distillation unit and platformer.

The planned shutdown, which took place in May, was to be the last maintenance closure on the refinery’s platformer before it is replaced by the CCR unit, which is scheduled to take place with commissioning of the TMH project.

Last year, the company let a contract to BOC New Zealand Ltd., an industrial gases subsidiary of Germany’s Linde Group, to build a plant aimed at reducing carbon dioxide emissions from operations at Marsden Point, which is due to be fully operational by yearend 2015 (OGJ Online, June 26, 2014).

The refiner also completed a series of upgrades last year to improve efficiency at the refinery’s hydrocracking unit (OGJ Online, June 17, 2014).

Contact Robert Brelsford at [email protected].