Researchers improve China’s Sulige Su-A gas production

Jinsheng Zhao

Xi’an Shiyou University

Xi’an, China

Hongtuo Yang

Shaanxi Yanchang Petroleum Group Co. Ltd.

Xi’an, China

Pan Li

PetroChina Changqing Oilfield Co.

Wushenqi, China

Yanqiu Gai

China Petroleum Logging Co. Ltd.

Xi’an, China

Researchers improved and stabilized production for 75 vertical wells on Su-A block of China’s Sulige tight sandstone gas field. They implemented measures that could guide the development of ultralow permeability gas reservoirs elsewhere.

Sulige field features complex sand bodies that make for low per-well production and rapid drops in reservoir pressure. Production often appears inconsistent with reservoir parameters.

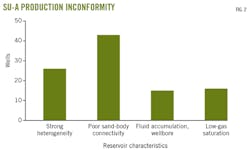

Operators blamed strong heterogeneity, poor sand body connectivity, wellbore fluid accumulation, and low gas saturation.

Researchers developed a classification system and selected 75 wells out of 232 wells on Su-A block in west-central Sulige field.

In successful efforts to increase production, researchers added perforations, prorated production, and compared gas recovery methods to drain fluid accumulation from selected wellbores starting in August 2017. They prorated production by making wellhead adjustments

China National Petroleum Corp. (CNPC) discovered Sulige field in 2000 in central Ordos basin, Inner Mongolia. CNPC brought Sulige on stream in 2003. Sulige field features complex reservoir heterogeneities caused by the interplay of sedimentary facies with diagenesis.

Major pay zones are the Shan-1 member of the Shanxi formation (Lower Permian) and He-8 member of the lower Shihezi formation (Middle Permian) at 3,200-3,500 m deep. The zones are 80-100 m thick.

The reservoir, intercalated by mudstone layers, has permeability less than 1.0 × 10–3 sq μm and porosity less than 10%.1-2

As of July 2017, Su-A block had 232 wells producing 171.67×104 cu m/d, with average production per well of 0.74 × 104 cu m/d. Average casing pressure was 5.63 MPa and total cumulative gas production was 32.24 × 108 cu m.

Fig. 1 shows the gas productivity decline curve 2012-17 even as new wells were brought on stream. As of July 2017, more than 50% of the wells produced less than 0.5 × 104 cu m/d despite reservoir porosity, permeability, and pay thickness indicative of better production.

Well classification

For the performance inconformity study, researchers analyzed sand body connectivity, reservoir heterogeneity, gas saturation, and liquid loading. They classified reservoirs by thickness, porosity, and permeability.3

They classified gas wells as static or dynamic to help determine production inconformity with static reservoir characteristics. The dynamic classification system best reflected well productivity.

Dynamic classification used production data such as unit pressure drop, pressure drop rate, and absolute open flow (AOF).4-5 Researchers found wells drilled in areas with promising reservoir parameters still could have poor production.

Reservoirs received static classification values based on logging data or core tests, which cannot represent conditions outside the wellbore. Operators must rely on static classification for development decisions because dynamic data is limited before large-scale development.

Sulige gas wells were tested for AOF before they went on stream, meaning AOF results only reflect flow characteristics of gas within induced fractures near wellbore. Gas well classification by AOF alone incorrectly reflects well productivity.6-7

Sand body connectivity is influenced by sedimentary characteristics of the sand body, reservoir fractures, and structural faults.8

Poorly producing wells exhibited low connectivity with adjacent wells on the same sand body. Poor sand body connectivity restricts gas flow, resulting in poor production despite promising static reservoir parameters.

For instance, the Shan reservoir’s sand body connects with poor gas zones in the north and east. As the sand body deteriorates, its thickness slowly shrinks.

Fluid accumulation in the wellbore gradually slows production, eventually halting it. When fluid accumulation exists, the differential in casing pressure and tubing pressure gradually increases as production decreases.

Researchers concluded that pressure curves and production curves can determine wellbore fluid accumulation.

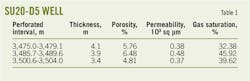

Gas saturation affects gas permeability. A gas well having low gas saturation has poor production. Table 1 shows zone statistics for the Su20-D5 well, which has an average gas saturation of 39.31%. Su20-D5 is in the He-8 reservoir.

Fig. 2 shows factors causing inconformity between well production performance and static reservoir parameters. Some wells had more than one cause of inconformity.

Recommendations

Researchers recommended adding batched perforations depending on reservoir type, classifying gas layers into three categories:

• Class 1 has a sand body thickness of at least 2 m with gas saturation greater than 50% and mud content less than 10%.

• Class II involves two types of gas reservoir. The first type features a sand body measuring 1-2 m thick with at least 45% gas saturation and shale content of 10% or less. The second type involves reservoirs featuring a sand body at least 2 m thick, gas saturation of at least 45%, and a shale content greater than 10%.

• Class III also includes two types of reservoirs. The first is a sand body measuring 0.5-1 m thick. The second has a sand body 1-2 m thick with a shale content greater than 10%.

Table 2 shows some of the reservoir classification results used to select poor-preforming gas wells, dividing them into batches to reperforate. Some Sulige gas wells show low bottomhole pressure after having produced for years.

Researchers recommend prorating production through wellhead adjustments to prolong stable rates. They also recommend additional study to determine how to calculate prorated production so individual wells can fulfill anticipated capacity.

If prorated production is too high, it shortens the duration of stabilized production. If the prorating is too low, the well’s production capacity will not be fully realized.

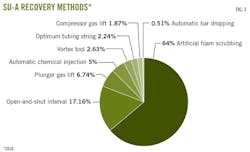

Producers have tried various gas recovery methods on the Su-A well block to drain fluid accumulation from wellbores. Fig. 3 shows methods used with artificial foam scrubbing as the most common. Other methods work but higher costs and more extensive equipment needs made producers favor artificial foam scrubbing.

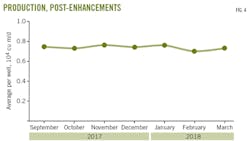

Fig. 4 shows the production curve after researchers implemented measures to improve and stabilize production. Post-enhancement, 6-month production averaged 0.74 × 104 cu m/d per well, up 25% compared with pre-enhancement production.

Acknowledgement

Authors acknowledge the support of the National Natural Sciences Foundation of China (51774236).

References

1. Li, T., and Huang, X., “Classification of horizontal wells based on dynamic data and its application in ultra-low permeability gas reservoirs,” Chemistry and Technology of Fuels and Oils, Vol. 53, No. 1, March 2017, pp 123-124.

2. Liu, G., Sun, M., Zhao, Wu, S., and Wang, X., “Characteristics and accumulation mechanism of tight sandstone gas reservoirs in the Upper Paleozoic, northern Ordos Basin, China,” Petroleum Science, Vol. 10, No. 4, December 2013. pp. 442-449.

3. Li, Y., Xu, W., Xiao, F., Liu, L., Liu, S., and Zhang, W., “Optimization of a development well pattern based on production performance: A case study of the strongly heterogeneous Sulige tight sandstone gas field, Ordos Basin,” Natural Gas Industry B., Vol. 2, No. 1, January 2015, pp 95-100.

4. Fan, Z., Zhang, S., Liu, J., Jou, X., “Effect of the chemical composition of formation water on gas well productivity,” Chemistry and Technology of Fuels and Oils, Vol. 30, No. 3, July 2014, pp. 252-256.

5. Li, Q., Ye, L., Gai, Z., and Li, Y., “Influence of bound and mobile water on gas well production in a low-permeability sandstone gas reservoir,” Chemistry and Technology of Fuels and Oils, Vol. 53, No. 2, June 2017, pp. 263-273.

6. Luo, R., Han, Y., Yu, S., Fan., J., Wen, X., and Ke, Y., “Production Performance Analysis of Hydraulically Fractured Horizontal Wells in Sulige Gas Field,” International Petroleum Technology Conference, Beijing, Mar. 26-28, 2013.

7. Xiao, W., Wu, X., and Liu, X., “Simplified graphical correlation for determining flow rate in tight gas wells in the Sulige gas field,” Petroleum Science, Vol. 5, No. 3, August 2008, pp. 258-262.

8. Hu, W., Li, X., and Wu, K., “The model for deliverability of gas well with complex shape sand bodies and small-scale reserve of Sulige Gas Field in China,” Journal of Petroleum Exploration and Production Technology, Vol. 5, No. 3, September 2015, pp. 277-284.

The authors

Jinsheng Zhao ([email protected]) is an associate professor at Xi’an Shiyou University, China. He primarily researches low-permeability oil and gas field development. He earned a PhD (2008) in oil-gas field development engineering from China University of Petroleum, Qingdao, and an MS (2005) in oil and gas storage and transportation engineering from Xi’an Shiyou University.

Hongtuo Yang ([email protected]) is an engineer working in Shaanxi Yanchang Petroleum (Group) Co. Ltd.’s Research Institute. His research specializes in gas reservoir development and evaluation. He earned an MS (2016) in petroleum engineering and a BS (2013) in petroleum engineering, both from Xi’an Shiyou University.

Pan Li ([email protected]) is a senior engineer working at PetroChina Changqing Oilfield Co.’s third gas production plant. He researches gas reservoir development and surface data gathering. He earned an MS (2012) in petroleum and natural gas engineering and a BS (2002) in petroleum engineering, both from Xi’an Shiyou University.

Yanqiu Gai ([email protected]) is an engineer working for China Petroleum Logging Co. Ltd.’s Oil and Gas Evaluation Center. She primarily researches gas reservoir development and evaluation. She earned an MS (2015) in oil-gas field development engineering from Xi’an Shiyou University and a BS (2011) in packaging engineering from Jiangnan University, Wuxi, China.