NPRA Q&A—2: Discussion expands to include coking, corrosion

This second of three articles that presents selections from the 2010 National Petrochemical and Refiners Association Q&A and Technology Forum (Oct. 10-13, Baltimore) continues a discussion of safety and also covers coking and corrosion.

The first installment based on edited transcripts from the 2010 event (OGJ, July 4, 2011, p. 80) deals with safety and process operations. The final installment (OGJ, Sept. 5, 2011) will highlight gasoline processes, especially dealing with safety, alkylation, and naphtha hydrotreating.

The session employed five panelists (see accompanying box). The only disclaimer for the panelists was that they discuss their own experiences, their own views, and the views of their companies. What has worked for them in their plants or refineries might not be applicable to every situation, but it can provide sound guidelines for what would work to address specific issues.

The panel… • Jim Johnson, hydroprocessing and crude/vacuum technologist, Marathon Petroleum Co. LLC • Frank Tracy, advising engineer, ConocoPhillips Co. • Ralph Goodrich, principal consultant, KBC Advanced Technologies Inc. • Doug Meyne, business development manager, Champion Technologies Inc. |

Safety

What testing procedures do you use for emergency shutdown valves? What are the parameters you measure and the acceptable values?

Johnson: Each Marathon refinery has its own mechanical integrity program containing detailed inspection, testing, and preventive maintenance tasks for each of the three equipment classes of shutdown devices. Those are emergency isolation valves (EIVs), emergency shutdown devices (ESDs), and SIS (safety instrumented systems); each has different requirements.

For EIVs, we only test them off-line, a full test of the driver. These tests are done biennially if they can be done on the run; otherwise, only in turnaround. We do a full stroke test. We verify the DCS [distributed control system] alarms, position indication, and valve closure and do an internal valve inspection, if the test occurs during turnaround.

For ESDs, if we are able to test them on line, we will do them annually. Otherwise, off-line inspection will be performed during turnarounds.

Each SIS, the third class, will have its individual safety requirement specification for that shutdown device. The specification contains detailed testing procedures for each of the shutdown valves. If it is a Class VI for a heater, then it is tested in bubbles per minute when down. If there is a way to bypass that valve and do it on line with a full test, then it is done every 5 years; otherwise, it is off-line during turnaround.

When I saw this question, I did not know exactly what the person wanted to know. So, if it was whether we do full or partial, then my response is that we no longer do partial testing of shutdown valves. They are all done full test, and we will not do one if it jeopardizes the unit running. That is why we do them only during shutdowns or turnarounds.

Tracy: ConocoPhillips has developed guidelines for emergency shutdown valve testing. The target frequency for testing is one turnaround cycle. That testing frequency is increased, however, based on individual application or to achieve the safety integrity level required by layers-of-protection analysis.

For shutdown valves that do require testing between turnarounds, we put in bypass valves. Our testing includes leak-testing the plug and seat in the as-found condition, disassembly inspection repair of the valve and actuator, and then reassembly, including a final leak-test of the plug and seat for final verification.

Johnson: The appropriate required testing of emergency shutdown valves is included in each Marathon refinery's mechanical integrity (MI) program and complies with the Process Safety Management regulation of the US Occupational Health and Safety Administration and the US Environmental Protection Agency's Risk Management Plan regulation.

Inspection, testing, and preventive maintenance (ITPM) plans are detailed for each equipment class, which includes emergency isolation valves, emergency shutdown valves associated with emergency shutdown devices pre-ANSI/ISA S84.00.01, and Safety Instrumented Systems as defined by ANSI/ISA S84.00.01.

The minimum ITPM tasks for EIVs includes a full stroke test, verification of DCS/HMI [human-machine interface] alarms, position indication, valve closure, and internal valve inspection. The testing will only be off-line and include a full test of the driver. If the EIV is where it can be isolated on the run, then the valve will be tested biennially except for the internal valve inspection, which is only done during turnarounds.

If the valve cannot be isolated on the run, then all testing will be completed during turnarounds. Limit switches must be satisfied that the valve travels fully open and closed. The internal valve inspections are to be conducted by a qualified inspector; if internal damage is observed, an appropriate repair plan will be developed, which may include leak-testing after repairs.

Emergency shutdown valves associated with ESDs are to undergo a full-function test annually if the ESD was designed for on line testing or will be tested during turnarounds, if not designed for on line testing.

Valves associated with SISs undergo testing detailed in the individual safety requirement specification (SRS). An example of a notable additional requirement for SISs is that heater shutdown valves (Class 6) are leak-tested with the leak rate measured in bubbles per minute that must pass the leak-test tolerance in accordance with ANSI B16.104-1976. These valves are leak-tested on either a 5-year interval, if available on line, or the turnaround interval if not available on line.

We no longer perform partial-function tests on shutdown valves, only full tests.

Coking

In your experience, what are the implications on coker heater run length and coke drum operations with the following feedstock quality: contaminants (Na, Ca), low saturates or high asphaltenes, crude compatibility, solvent deasphalt (SDA) pitch, low asphaltenes, and high saturates?

Tracy: I am going to speak first to the heater run-length portion of the question, and then I will follow with some discussion of drum operations.

There are at least three main mechanisms by which heater tubes become fouled in cokers. The first one is inorganic material deposition or precipitation, the second is rapid asphaltene precipitation, and the third is coke formation. All of these may contribute to chronic heater fouling. However, we have identified the first two in conjunction with specific episodes of rapid fouling.

I am going to talk first about inorganic fouling mechanisms. Inorganic fouling typically occurs in the top of the radiant section or even in the lower part of the convection section of the heater. Suspended solids in the oil are often a source for these inorganic materials. These materials may be inherent in the crude, or they may be introduced into the oil as part of upstream processing, transportation, or production before their arrival at the coker.

Desalters are generally effective at removing the crystalline salts from the oil—think of sodium chloride—but not generally as effective in removing some of these other inorganic solids. The sodium and calcium noted in the question are certainly common problems in cokers: 15-20 ppm sodium is a common industry rule of thumb as a maximum for sodium in feed to the coker. Of course, we would like to see numbers below that. Crude-unit caustic injection for chloride control will lower sodium loading in the vacuum resid.

Because we have seen large quantities of calcium in some of the scale removed from some heaters as well, we know that calcium is another inorganic material that causes problems in certain cases.

Silicon is an inorganic that has also caused major problems in at least three of our cokers. It has also been identified with certain crudes, and the source is most often silicates or silica (quartz) in the crude oil. In additional, silicon-based antifoam has been identified as a possible foulant in one of our units.

Iron is another inorganic material we have seen in heater-tube fouling, and the common sources are iron sulfides and other iron compounds that, again, make it through the desalter and end up in the feed to the coker.

There are other inorganics associated with fouling. Aluminum and magnesium are often associated with some of the silicates, as well as barium, although these are less common than the four I have mentioned. Well workover chemicals add to the amount of inorganic material in the crude supply.

As you know, the inorganic materials don't lend themselves well to on line spalling or steam-air decoking and often require pigging to be properly removed from the heater tubes.

Ideally, these inorganic materials will be handled upstream of the coker and you might be able to achieve some benefit from desalter operation changes and in managing caustic injection for chloride control in the crude unit. You may also be able to get some relief from crude suppliers.

At the end of the day, however, it becomes an economic decision as you deal with certain crudes and recognize that crude selection affects heater-run length. You have to value that crude appropriately, based on that impact because you are often just stuck with what comes in the crude. In addition, refinery slop and possibly FCC [fluid catalytic converter] slurry oil have inorganics that might contribute to fouling.

The second area is asphaltene precipitation. We have experienced episodes in which we have seen asphaltene precipitation occur rapidly. It tends to occur in the upper radiant and lower convection sections. Sometimes this has links to highly paraffinic materials or low asphaltene stability materials such as a resid hydrocracker bottom stream.

Within ConocoPhillips, we use asphaltene stability testing and coking propensity testing to identify feeds that are problematic and have feed-compatibility issues. Distillate recycle technology, which recycles either a coker distillate stream or a coker gas oil stream through the heater and coke drums, will help with asphaltene stability.

The final area of concern is coke formation: the traditional coker fouling mechanism. The heaviest coke formation tends to be in the lower radiant section of the heater, and turbulence and velocity can be used to help minimize the amount of time that a molecule is at that hot tube wall. Velocity steam is used for this purpose, as is distillate recycle, which also provides a yield benefit.

As to the drum operations portion of the question, the inorganic materials do not generally create any drum operation problems. If you operate an anode coker, however, then the coke quality issues can be significant with certain crudes and some of those contaminants. Feedstock, of course, impacts drum operations. The top of the coke bed has had the least amount of time to complete the coking reactions.

So, if you have a less reactive feedstock such as a resid hydrocracker bottom stream, then that material may be less converted to coke, particularly in the top of the bed. When the drum is finished, therefore, that material may be a little bit more like tar than a vacuum resid feed would be. And, as a consequence, it tends to plug off some of the channels in the upper part of the coke drum and lead to more hotspots and blowouts.

In fact, we have seen that situation in two of our cokers that fed some amount of resid hydrocracker bottoms material. In addition to adjusting temperature, we have limited the amount of that feedstock to those cokers to help with the hot spots and blowouts.

Goodrich: I essentially agree with everything that Frank has commented on so far. I just want to emphasize a few of the areas, one being the caustic injection.

This injection rate is something we target when we feel some refiners may be pushing that a little bit too hard. You really want to monitor the amount of caustic that you use. In fact, when we do a grassroots design of a crude unit, we will provide injection facilities. We would rather not pipe it up but prefer to have it available only if it is actually needed.

Also, the high asphaltenes content in the feed can significantly increase your furnace fouling rate. It can also increase the tendency to produce shot coke and cause coke drum cooling problems and high thermal stresses, which can result in coke drum cracks.

Another point, particularly in some locations in Canada, is that there could be a high solids content in the feed, as high as 2%. This content can cause fouling in the coker furnace in the same locations that Frank mentioned and in the coke drum's overhead line and the main fractionator's wash section.

Finally, there are definitely crude compatibility issues to be aware of. Dissimilar crude and resulting coker feeds can result in difficulties in drum cooling and hot spots. Foaming can be a problem as well. Some of these problems with dissimilar coker feeds can be addressed with procedural changes; but at some point, limiting the offending crude is the only economic choice.

In general, to avoid these problems, keep the feeds to coker as similar as possible. Do not mix, for example, highly asphaltenic feeds with highly paraffinic feeds.

Corrosion

Please discuss advanced methods you use to monitor corrosion in operating units. Are any of these used in conjunction with the DCS for continuous on line monitoring?

Johnson: To answer this, I had to ignore the comment of advanced methods because most of our methods are not really advanced.

We utilize three methods for corrosion monitoring. The most advanced would be the multipoint resistance measurements for naphthenic acid. Two of our refineries utilize those. Then, basically, we have ER [electrical resistance] probes and corrosion coupons.

Two refineries utilize the multipoint resistance measurements. One uses [iiccor Ltd.], the field signature method; the other refinery uses the GE Betz RCM [resistance corrosion monitoring] system. Neither of these RCM systems is monitored continuously. The vendors take periodic readings, interpret the corrosion data, and send memos to the refinery, but this monitoring is not done continuously.

ER probes, likewise: nothing continuous. But one of our refineries uses data loggers for relatively real-time. It is not continuous and is not brought back to any DCS.

And lastly, the most nonadvanced are corrosion coupons. We are still using these heavily in our systems, and we use them for metallurgy selection, not just corrosion.

Meyne: To build on what Jim said, part of Champion's standard corrosion-control program package is installation of corrosion-rate data loggers in the critical areas of the system. This [Fig. 1] is a picture of the data logger and an example of a wireless bus. I have not seen any of these recently that have been tied directly into the DCS due to the significant cost associated with making this connection.

We typically see these data loggers hooked up to standard ER probes. You can set them to take as many corrosion rates per day or week as you would like. To retrieve the data, you take a hand held device to the logger, plug it in as you normally would to an ER probe, download all the data, and then enter it into your software to get your rates. The more corrosion rates per day you set the data logger to read, the more frequently you will have to download the data to the hand-held device.

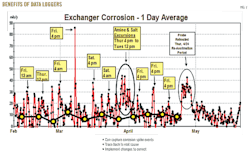

This slide [Fig. 2] is an example of why we use data loggers as part of our standard corrosion-control programs. Normally, ER probes are only read once or twice a week, thus generating minimal corrosion-rate information. Corrosion is very episodic. Obtaining only one or two corrosion rates per week does not allow you to see these "corrosion episodes."

We are not nearly as concerned with seeing weekly average corrosion rates of 5 mils/year (mpy) as we are with seeing the 2 or 3-hr windows of time during the week when the corrosion rates may spike to 80 mpy or 100 mpy.

[Fig. 2] shows the output of a data logger that was set to take six readings a day. As you review the data, you can see obvious spikes in corrosion rate. For the most part, these spikes are occurring roughly every Friday evening or Friday night. Tracing it back, we found that there were some abnormalities in the tank farm with respect to slop dumps back to crude. The tank farm was essentially transferring all the weekly slop from the refinery to the crude tanks all at once on Friday evening instead of daily as their procedure stated.

Once this issue was identified, we were able to get the slop-handling practices changed. The leveling of the corrosion rates seen on the far right side of the graph represents the time period after the handling practices were changed and the corrosion spikes were eliminated.

For comparison purposes, if you were just going out there every Wednesday afternoon to take a normal one-corrosion-rate reading on an ER probe, then the results are represented by the big yellow circles [Fig. 2].

This comparison shows the importance of the data loggers and getting more than just the traditional one-corrosion-rate reading per week. If the only corrosion rate data you had on the system was that represented by the "yellow dot" trend, you would have missed all of the corrosion spikes and, in this case, the issues with the slop-handling practices that were leading to increased corrosion in the overhead system.

Mike Nugent (Northern Engineering Consultants Inc.): Continuous UT [ultrasonic thickness] transducers now exist that can be mounted on high-temperature operations.

We have had some on transfer line service at 650º F. for 5 years now. They are ultrasonic thickness measurements to give pipe thickness readings. They provide real thickness monitoring as opposed to the correlations from corrosion probes. The big problem has been having a sensor that would last for 5 years or more. So, there are now ultrasonic thickness capabilities for continuous high-temperature monitoring.

The question of tying it into the DCS again becomes less a technology question and more an information question. Your computer folks have to go with wireless transmission, which either is a benefit or is banned in certain refineries, and also the logistics of tying it in.

Sometimes it is easier to put a data logger at a remote station to acquire corrosion data, but I know no one who has gone to a real-time monitoring of corrosion, as far as setting crude rate. The capability does exist, and the ability to tie it into the DCS becomes more an IT issue than a technology issue because there is wireless technology and hard cable. Usually, though, most people find it easier to leave the data logger there, as you have for the corrosion probes, and record them on a batch basis.

Johnson: Marathon utilizes three methods of corrosion monitoring in crude and vacuum units: multipoint resistance measurement (iicorr, FSM, GE Betz RCM) systems for naphthenic acid corrosion, ER probes, and corrosion coupons. While use of coupons may not be considered an "advanced method" for monitoring corrosion, we continue to use them in our refining system.

Two of our refineries have installed multipoint resistance measurement technology in areas that previously experienced naphthenic acid corrosion. One refinery uses iicorr's field signature method system, while the other location utilizes GE Betz's RCM system. Neither of these systems is monitored continuously. Rather, spot readings taken routinely with the calculated corrosion rate are reported to the refinery.

A mix of ER probes and coupons is used in our refineries. Either is used, depending on the corrosion history of the particular circuit and how frequent corrosion data are required. One of our refineries utilizes a data logger on the ER probe signal to capture data on a near-continuous basis, whereas at all other locations the probes are typically monitored weekly.

We have no examples in which data are sent to the DCS.

Corrosion coupons are still widely used, mainly for general corrosion monitoring. At one refinery designed for high TAN [total acid number] crudes, corrosion coupons of various less-corrosion-resistant metallurgies are placed in select circuits to provide data on the relative corrosivity of certain crudes and cuts. These data will be used in an effort to better optimize metallurgy requirements in the future and provide pertinent corrosion data if a common crude is processed at another location.

Meyne: Traditionally, standard corrosion coupons and ER probes are used to monitor corrosion in operating units. The main limitation of these types of corrosion monitoring devices is the limited amount of data they generate, usually one to two corrosion rates a week if not fewer.

Corrosion in operating units tends to be episodic and can be attributed to many changes in operating conditions. Under normal conditions, a system may see 1-5 mpy corrosion rates; however, the rates can spike up to hundreds of mpy during one of these corrosion episodes. It is critical to identify these corrosion spikes when they occur so that changes in operations or chemical additions can be made immediately to resolve the issue. By reducing the time of these spikes, the overall corrosion rate is minimized.

In order to "see" these corrosion spikes and overcome the limited data-acquiring capabilities of traditional coupons and ER probes, Champion utilizes data loggers to obtain multiple corrosion rates per day. Standard ER probes are hooked up to the data loggers that have the ability to store several days of corrosion rates.

Typically, the rates are uploaded to a hand-held unit out in the field and then downloaded to a PC. The data loggers can also be tied directly into a DCS via cables or wireless buses to yield true "real time" corrosion rates. These data loggers are part of our standard corrosion monitoring package and can be set to read corrosion rates on any given time interval.

Eberhard Lucke (Commonwealth Engineering & Construction LLC): I have not seen any operation yet that would show corrosion monitoring in the DCS. The most advanced I have seen (and I may be outdated on that) was installed corrosion probes with easy connections to a data logger (hand held, [personal digital assistant] PDA-like device). A dedicated maintenance person would walk the unit in certain intervals and collect all the data from the corrosion probes via data logger.

The data would then be transferred electronically into spread sheets and used in an off-line unit monitoring system. I assume that with new wireless technologies and internet connections, automatic data transfer into databases, and even into the DCS, should be no problem, if required.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com