Verde, Diamondback partnering on Permian basin GTG plant

Verde Clean Fuels Inc., Houston, is partnering with Midland-based Diamondback Energy Inc. subsidiary Cottonmouth Ventures LLC for joint development of a first-of-its-kind natural gas-to-gasoline (GTG) plant in Martin County, Tex., in Midland basin of the Permian.

To be equipped with Verde’s proprietary synthesis gas (syngas)-to-gasoline plus (STG+) liquid fuels technology, the proposed project will use a feedstock of stranded or otherwise-flared associated natural gas from Diamondback’s Permian basin operations for commercial-scale production of almost 3,000 b/d of fully finished reformulated blend stock for oxygenate blending (RBOB) gasoline.

In addition to detailing the joint development agreement (JDA) between Verde and Cottonmouth Ventures and providing the latest update on the planned Martin County GTG plant, this article presents an overview of the STG+ process and its potential future applications in converting syngas derived from natural gas and biomass feedstock into reduced carbon-intensity fuel.

Partnership, GTG plant overview

In early February 2024, Verde and Cottonmouth Ventures entered a JDA outlining the partners’ proposed development, construction, and operation of a plant in Martin County that aims to produce commodity-grade gasoline from associated natural gas feedstock supplied from Diamondback’s surrounding Permian basin production sites.

Intended to provide a pathway for the partners to reach final definitive documents and final investment decision (FID) on the proposed project, the JDA sets out the foundation for future contracts between the parties, including an operating agreement, ground-lease agreement, construction agreement, license agreement, and financing agreements, as well as conditions precedent to FID.

The JDA follows Diamondback’s February 2023 $20-million equity investment in Verde, under which the independent oil and gas producer entered into an equity participation rights agreement. The agreement requires Verde to grant Cottonmouth Ventures the right to participate in joint development of installations in the Permian basin using Verde’s STG+ technology to produce gasoline from gas feedstock sourced from Diamondback’s West Texas Permian operations (Fig. 1).

The partnership intends to enable Diamondback to mitigate the flaring of natural gas while producing a high-margin product from gas streams in the pipeline-constrained Permian that are currently price disadvantaged compared with other US natural gas basins.

The proposed Martin County GTG plant would consume about 34 MMcfd of natural gas supplied by Diamondback to produce 2,950 b/d of RBOB-specification gasoline that requires no further refining.

Estimated in January 2024 to require an overall capital investment of about $325 million, the GTG plant will be at an existing Diamondback site in Martin County equipped with access to power, water, and gas-metering infrastructure. Ultimately, the location would have access to more than 50 MMcfd of deliverable gas feedstock from Diamondback, Verde said.

In addition to becoming the first commercial-scale implementation of Verde’s STG+ technology, the modular-based plant would be the first of what Verde hopes will become a template for additional plants both in and beyond the Permian.

“We believe that [the Martin County GTL plant] should be the first of several projects with Diamondback, and that this Permian basin project should be a case study for how to monetize disadvantaged, flared, economically, or physically stranded natural gas across the globe,” Ernie Miller, Verde’s chief executive officer, told OGJ.

“[This first proposed] Diamondback project demonstrates a solution to a problem that exists in many associated gas producing basins in the US and beyond,” Miller said of Verde’s longer-term goal.

Project status, providers

In early May 2024, Verde confirmed to OGJ that preliminary front-end engineering and design (pre-FEED) for the Martin County GTG plant was under way.

Verde, which hopes to execute the formal FEED contract soon, said it anticipates the partnership will take FID in first-quarter 2025 for targeted start of commercial operation sometime in second-half 2026.

While Verde did not identify service providers participating in the pre-FEED and FEED stages, the company did confirm to OGJ that Koch Modular Process Systems LLC, Paramus, NJ, will provide services related to the gasoline reactor system of plant’s STG+ process.

Other equipment—including a steam methane reformer, compressors, and the balance of the plant—will be sourced from yet-to-be-identified providers, Verde said.

STG+ process, future applications

Verde’s STG+ technology has been validated through nearly 11,000 hours of operation via multiple campaigns to produce on-spec methanol and gasoline from natural gas-derived syngas at the company’s demonstration plant in New Jersey (Fig. 3).

While the Martin County GTG plant will focus on gasoline production, Verde said it is continuing to develop STG+ technology as well as develop or acquire additional technologies for potential future applications in production of low-carbon diesel and aviation fuel from available waste feedstocks elsewhere in the US and globally.

Verde told OGJ the demonstration plant has allowed it to prove the process, enabling technical confirmation by independent parties of the technology’s commercial scale-up resulting in a financeable and insurable plant.

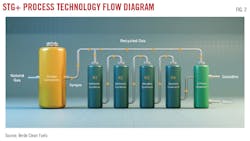

Designed to enable production of commodity-grade, drop-in transportation fuels from syngas obtained from either natural gas or biomass waste feedstocks, the STG+ system entails a four-step process involving a series of fixed-bed reactors in a single-phase, continuous process loop.

For the proposed Martin County GTL plant, the process will consist of generating syngas from natural gas feedstock. Derived syngas next moves into the first and second reactors (R1, R2) where it passes through catalyst beds and is converted into methanol.

Product gas from R2 then passes to the third reactor (R3), which contains catalysts to convert the gas into synthetic gasoline hydrocarbons that are subsequently routed to a fourth reactor (R4) for further treatment to remove undesirable components and improve gasoline octane.

In the final step of the process, the hydrocarbon mixture enters a three-phase separator where non-condensed gas is separated out for recycling to R1. Following this separation process, only final on-spec synthetic gasoline and process water remain.

Fig. 2 shows a flow diagram of the STG+ process.

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.