Northwind expanding to meet Delaware basin off-spec needs

Northwind Midstream Partners LLC is expanding its integrated natural gas processing, gathering, compression, and carbon capture and sequestration (CCS) system in Lea County, NM, to accommodate increased production and management of off-spec gas—gas containing high levels of carbon dioxide (CO2) and hydrogen sulfide (H2S)—in the Permian’s Northern Delaware basin of southeastern New Mexico.

Following its purchase of assets originally built and operated by Houston-based Salt Creek Midstream LLC in midyear 2023, Northwind recently completed a major expansion of an existing gas plant and is moving forward with additional growth projects across its system aimed at sustainably enabling producers to unlock the region’s otherwise-stranded sour gas supplies.

In addition to providing a background and overview of Northwind’s current operations, this article examines the operator’s newly launched plans to further meet steadily accelerating demand for off-spec gas treatment.

System history

Founded in December 2022 by Houston-based private equity firm Five Point Energy LLC, Northwind was formed specifically to develop, own, and operate off-spec gas infrastructure in the Permian to address constrained production of regional gas due to high CO2 and H2S concentrations, a shortage of midstream installations equipped to move it, and increasingly stringent regulations forcing producers to better manage operational emissions and flaring.

According to documents discoverable from the government of New Mexico, Northwind completed purchase of Salt Creek’s Ameredev South gas processing plant—located about 7 miles southwest of Jal, NM, in Lea County—as of June 16, 2023.

Under Salt Creek’s ownership, the Ameredev South plant—which Salt Creek idled in late-February 2020 and never returned to service—was designed with a nameplate capacity to process up to 200 MMcfd of sour gas at pressures of 100-200 psig from well sites in both Lea and Eddy Counties, state documents showed.

In addition to the plant—which housed installations for acid-gas compression (via an electric-drive, three-stage reciprocating acid-gas compressor), amine treating, and glycol dehydration the Ameredev South system included:

- Sour-gas gathering lines from production wells to the plant.

- Treated acid-gas (TAG) lines running from the plant to acidgas injection (AGI) wells.

- Two AGI wells.

Sweet-gas volumes from the plant were pipelined across state lines for further cryogenic processing at Salt Creek’s 400-MMcfd Pecos gas processing plant in Pecos, Tex.

New Mexico’s government records indicated future operatorship of an acid-gas injection well,

planned but never completed for the Ameredev South plant, also was approved for transfer to Northwind from Salt Creek as of mid-August 2023.

Following the acquisition, Northwind renamed the Ameredev South system the Titan off-spec gas gathering, compression, treating, CCS, and processing system, after which it undertook a series of construction projects to upgrade and expand its integrated operations.

Initial expansion

In mid-March 2025, Northwind confirmed completing the first leg of its broader Titan Phase 1 buildout (Fig. 1).

Underpinned by long-term commitments and greater than 165,000 dedicated acres from several of the basin’s leading public and private independent oil and gas producers, Northwind said the newly commissioned upgrade and expansion of its Titan complex and initial gas-gathering and compression network involved adding:

- 100 MMcfd of high-circulation amine treating capacity at the Titan complex (Fig. 2).

- A second deep AGI-CCS well (Fig. 3).

- Four additional National Association of Corrosion Engineers (NACE)-compliant compressor stations with the ability to handle about 200 MMcfd of aggregate capacity, expandable up to 400 MMcfd.

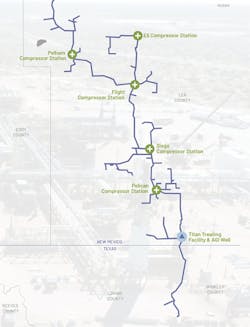

With these units in service, Northwind’s Delaware basin sour-gas system now consists of:

- 150 MMcfd of high-circulation amine treating capacity.

- Two AGI-CCS wells.

- More than 200 miles of large-diameter NACE-standard pipelines designed specifically to manage produced gas with high CO2 and H2S levels.

- Five compressor stations (Pelican, Siege, Flight, Pelham, Eli) with a combined 41,750-hp of

compression capacity across its Lea County network (Fig. 4).

Another 50 MMcfd of amine-treating capacity scheduled to enter service by midyear 2025 will complete Phase 1, boosting total amine-treating capacity at the Titan complex to 200 MMcfd, Northwind said.

Second expansion

Industry estimates suggest more than 7,500 remaining well locations and at least six geologic production benches could be developed across the region, given additional treating and AGI-CCS well capacity tailored to high concentrations of CO2 and H2S. On this basis, Northwind also announced in March 2025 reaching final investment decision to move forward with a second-phase expansion that would double the Titan complex’s amine-treating capacity to 400 MMcfd by 2026.

On Mar. 17, the operator completed issuance of a new $700-million senior-secured first lien term loan, the net proceeds of which Northwind will use to repay existing financing commitments as well as help fund the proposed buildout.

While Northwind did not reveal further details regarding the planned expansion, the New Mexico Environmental Department (NMED) on Apr. 15 published a copy of the operator’s revised New Source Review permit application for the project as part of a required 30-day public comment period.

The application states the project—officially named Titan Treater Plant 2—entails the addition of a 220-MMcfd sour-gas treating plant designed to handle high-pressure inlet field gas that, upon entering the plant, will be compressed using gas-fired engines.

Post-compression, the inlet gas will travel to a dual-unit amine-treatment system for CO2 and H2S removal, after which the resulting acid-gas stream will be directed to five electric-driven compressors (including a spare unit), that will inject the acid gas underground via AGI wells.

The sweetened gas leaving the amine-treating units will first be sent through a triazine contact tower to remove any residual sulfur compounds, after which the gas will be dehydrated using triethylene glycol units and compressed via gas-fired turbines for sales.

Condensate separated in the inlet-slug catcher will undergo further processing in a sour-condensate stabilization train, with stabilizer overhead gas to be recycled into the plant inlet via three electric-driven compressors.

Stabilized condensate will be stored in four 1,000-bbl tanks to await being pumped offsite. In case of pipeline unavailability, however, the stabilized condensate will be loaded via truck for offsite delivery.

Any emissions from this stage of the process will be routed to the tank header via a vapor return line.

Liquids collected via the plant’s closed-drain system will be directed to two 400-bbl slop-water tanks and hauled offsite on trucks.

The plant will include a redundant vapor-recovery unit to control emissions by routing vapors

from the condensate and slop water tanks as well as truck loading back to the inlet.

Major equipment to be added as part of the new plant includes:

- Seven 2,065-hp compressor engines.

- Five 1,380-hp compressor engines.

- Six turbines rated at 6,370 hp each for power generation.

- Two triethylene glycol dehydrators and two associated glycol regenerator heaters.

- One acid-gas flare.

- One process flare.

- Slop-water loading.

- Condensate loading.

- Two slop-water storage tanks.

- Four condensate storage tanks.

- A spent-triazine storage tank.

- Five electric-drive acid-gas compressors.

- One stabilizer heater.

- Three electric-drive stabilizer overhead compressors.

Public comments on the proposed Titan Plant No. 2 were due by May 15 to NMED, which upon

opening the comment period, announced its preliminary determination to issue Northwind an air-quality construction permit for the project on or before July 2, 2025.

Additional plans

Alongside its Titan Plant No. 2 project, Northwind also plans to add an AGI-CCS well and third processing plant to its Delaware basin operations.

As of late-April 2025, the operator was seeking approval of a permit from New Mexico’s Oil Conservation Commission (OCC) for disposal into the proposed Titan AGI #4 well as an additional redundant AGI well. The company also was pursuing approval for a shared maximum daily injection rate of 28.8 MMcfd of TAG for disposal through either or both its existing Salt Creek AGI #2 well and the planned Titan AGI #4 well, acccording to an OCC docket.

The injection stream would consist of TAG comprised of about 80% and 20% CO2 and H2S, respectively. After moving to approve the requested permit pending certain changes at a Mar. 20 meeting, OCC was scheduled to hear a presentation of the final amended order at its Apr.

21 meeting.

In mid-March, Northwind said it also is building a 75-MMcfd gas-treatment complex in northern Lea County that will be known as the Pelham complex. While project details remain unavailable, Pelham is one of the five compressor-station locations Northwind operates in the region (Fig. 5).

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.