Optimization guides similar gas plants to different strategies

Alan Dove

Enable Midstream Partners LP

Oklahoma City

Veeral Mehta

Steve Hendon

Mark Roop

eSimulation Inc.

Webster, Tex.

| Based on a presentation to the GPA Annual Convention, Apr. 13-16, 2014, Dallas. |

Operating natural gas processing plants under fluctuating commodity pricing, inlet conditions, and equipment performance capabilities is difficult. Under such conditions, processors typically operate their plants in either full ethane recovery or full ethane rejection.

In early 2000, Enable Midstream Partners LP, Oklahoma City, began implementing gas plant optimization software for its cryogenic plants and discovered a continuum of desirable operating points within each mode. Rigorous gas plant optimization determines where to operate along such a continuum to achieve the highest possible returns under all operating and economic conditions.

Seven Enable Midstream gas plants currently employ optimization. An additional plant optimizer is to come online at the new 200-MMcfd McClure gas plant that started up in Custer County, Okla., in January of this year.

This article describes the nonintuitive, often counter-intuitive guidance that optimization provides to achieve maximum daily plant profit margins. A case study of Enable Midstream's 200-MMcfd Wheeler, Tex., gas plant in the Texas Panhandle demonstrates how the nonintuitive set point guidance is beneficial.

The article will contrast optimization set point guidance at Wheeler compared with optimization set point guidance at the 200-MMcfd South Canadian plant–an identical plant with the same economics where the optimizer guided the plant to maximize profit using exactly the opposite set point guidance.

eSimulation performed a detailed study to describe this optimization guidance difference. The study describes the non-linear optimization response to fluctuations in inlet-gas composition (gallons of NGLs per Mcf of inlet natural gas; GPM) and economic conditions.

This article presents optimization study results and a 12-month pro forma example that shows the profit opportunity associated with optimizing operational and economic tradeoffs for cryogenic assets.

Optimizing gas plants

Optimization has been effective differently under varying economic environments. Fig. 1 shows the ethane margin at Mont Belvieu and Conway since 2000.

Between 2000 and mid-2005, ethane margins were fluctuating between low and negative values. In ethane-recovery mode, the optimization system often guided Enable Midstream's operators to reduce ethane-recovery targets to improve energy efficiency.

When ethane margins were negative and plants were operating in ethane-rejection mode, the optimization system modulated ethane-recovery targets to maximize propane production (typically) and to optimize energy efficiency.

Between mid-2005 and mid-2012, ethane margins were strong and optimization guided Enable Midstream's operators to maximize ethane recoveries. The solution also guided operators to manage constraints associated with midstream asset build-outs (i.e., reduce recoveries to allow processing of excess gas, manage NGL takeaway constraints to make heavier liquids, and manage to "provide or pay" liquids contracts).

Mid-2012 through November 2013 brought back low and negative ethane margins. Optimization once again provided nonintuitive guidance that benefitted Enable Midstream's gas plants, especially in rejection mode.

According to industry publications and presentations at the 2013 GPA meeting in San Antonio, these periods of NGL product imbalances, low product margins, and ethane-rejection operation will prevail over the next 5 years as the petrochemical industry builds to take advantage of abundant NGL supplies from shale basins.

Wheeler gas plant

Determining optimal operating targets for gas plants requires consideration of several key factors: ethane margin, propane margin, producer contract structures, inlet volume, inlet GPM, ambient conditions, compression energy, and the processing equipment's ability to perform under current fouling, efficiencies, and processing constraints.

The optimization system deployed at Enable Midstream's gas plants uses a rigorous, online, non-linear, thermodynamic model that calculates the cost of extracting the next gallon of NGL (given current equipment fouling, efficiencies, and constraints) and balances that cost against the revenue generated under prevailing commodity prices and producer contracts. The resulting optimization targets (column pressure, column temperature, subcooled reflux flow) are updated every 2 hr for operator implementation.

Enable Midstream chose to extend its optimization program to manage the new Wheeler, Tex., gas plant. It is designed to process 200 MMscfd of gas from Granite Wash shale. The optimizer was commissioned in January 2013, while the plant was being operated in ethane-rejection mode.

Before commissioning, the operational objectives were to keep ethane recovery low (10-12%) while increasing propane recovery (>90%). This was achieved by running the demethanizer bottoms temperature at about 116° F., the overhead pressure at around 215 psig, and the gas subcooled process (GSP) ratio at 0.38.

Interestingly, the optimization system guided operators to increase ethane recoveries and to achieve those targets with exactly the opposite set point strategy as was being employed. The optimizer guided plant operators to increase the demethanizer pressure to 235 psig, lower the demethanizer bottoms temperature to 100-102° F., and lower the GSP ratio to 0.33.

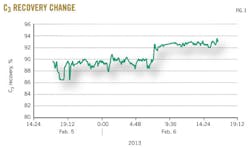

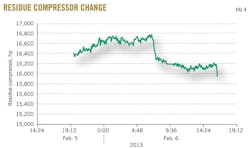

These adjustments increased ethane recovery to greater than 25%, provided a 1-2% increase in propane recovery, and reduced the load on the residue compressors (saving energy consumption) because less ethane was being recompressed. Figs. 2, 3, and 4 illustrate the changes in recovery and power consumption over 24 hr.

eSimulation compared the resulting changes in plant operation with the preoptimization baseline to evaluate performance improvements (Table 1).

Table 2 summarizes how the optimization system guided operators to realize maximum gas plant profits when comparing optimized performance with baseline (i.e., how the plant was running at the time of optimizer commissioning).

Table 3 shows the effect of comparing optimized performance with design recoveries.

The Wheeler plant optimization effort yielded the following:

• The optimal ethane-recovery target was much higher than the full ethane-rejection target. This allows for greater propane recovery, which made sense in the economic conditions present when the optimizer was commissioned.

• There was a large reduction in power use at the greater ethane recoveries. This is counter-intuitive. Usually, higher ethane recoveries require more residue compression horsepower to recompress the residue gas to pipeline conditions. In this case, however, there was much less ethane in the gas stream that had to be recompressed, resulting in lower power requirements.

• Optimization improves profits for gas processing assets and use of this tool yields the highest revenue for Enable Midstream's plant. In the first 3 months after commissioning, the project more than paid for all deployment costs and 3 years of optimization service.

South Canadian plant

Enable Midstream operates two relatively new gas plants about 100 miles apart, Wheeler and South Canadian. Enable Midstream's engineering group wondered why operational targets at Wheeler were opposite of those at South Canadian. They are of the same design and operated with the same economics.

The Wheeler plant's targets led to higher-than-design C2 recovery of about 25%, while optimization installed at the South Canadian plant was guiding operators to run at about 10% C2 recovery.

An offline simulation analyzed the effect of operating the South Canadian plant under the Wheeler plant optimization set points. The analysis showed that if the South Canadian plant were run under the targets for the Wheeler plant, the South Canadian plant would lose $1,700/day.

The analysis identified that the inlet composition at South Canadian contained a lower propane concentration than at Wheeler. The propane value upgrade from running at the higher ethane recovery at South Canadian would not offset the ethane losses at higher recovery rates.

During this period, the ethane margin was closer to breakeven and propane margins were attractive. Therefore, the optimizer sacrificed ethane losses to go after the propane at the Wheeler plant.

The analysis demonstrated that small changes in inlet composition can cause large operational shifts. These are the types of operating adjustments Enable Midstream would not have benefited from without rigorous optimization.

The results demonstrate why it is important to have optimizers in place all the time: Conditions change, and it is not always possible to predict conditions wherein nonintuitive moves are required to realize maximum profits.

Optimization study

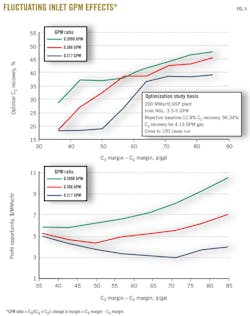

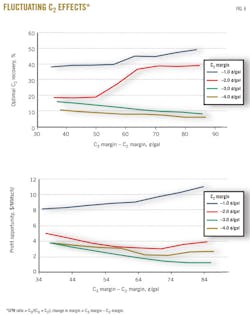

Enable Midstream's engineers were having trouble explaining to management the nonintuitive optimized set point guidance as conditions changed. The engineers performed a detailed study with an actual online optimization model taken offline to examine the effect of fluctuating inlet GPM and economic conditions on optimal plant operation.

Figs. 5 and 6 summarize the detailed analyses from more than 100 case studies.

A pro forma analysis quantified optimization benefits over 12 months. The methodology included the following steps: loading baseline conditions into the model, running it at each month's prices, and running an optimization case to see where the model would move the plant to realize maximum profits at that month's prices.

The baseline rejection operation was as follows:

• Inlet rate = 207 MMscfd.

• GSP plant.

• 9.00% C2 recovery.

• 96.32% C3 recovery.

• 4.22 GPM.

• Ethane: 8.997 mole %.

• Propane: 3.639 mole %.

• GPM ratio (C3/(C3 + C2)) = 0.294.

• Midcontinent economics.

• Mont Belvieu NGL delivery.

Table 4 presents the resulting 12-month pro forma.

Typical operational directives in ethane-rejection mode are to reduce ethane recovery while attempting to maintain propane recovery as high as possible. Note that the pro forma analysis puts this strategy in question:

• Optimal ethane recoveries fluctuate greatly compared with the full ethane-rejection baseline. Simply holding the target at minimum is only valid if the ethane margin is highly negative.

• Propane recovery is relatively flat, maybe even slightly less than the baseline.

• The determinant in this analysis was recompression energy. This point was unexpected because recompression energy is not typically considered in the ethane-rejection strategy.

The decision to go into ethane rejection and the optimal level of ethane rejection depend on product prices, gas prices, energy consumption, process capability, and inlet volume and composition, not simply ethane margin. All these variables must be analyzed to determine the best way to run the plant.

The authors

Alan Dove ([email protected]) is an expert processing engineer for Enable Midstream Partners (formerly Enogex Inc.) in its processing operations department and has held several positions since joining Enogex in 2000. Before joining Enogex, he worked in gas processing, refining, and petrochemicals for several different companies. Dove holds a BSChE (1972) from Oklahoma State University and is a member of the American Institute of Chemical Engineers and the Gas Processors Association.

Veeral Mehta ([email protected]) is optimization manager for eSimulation Inc., Houston, which he joined in 2008. He holds a BSc (2003) in chemical engineering from the University of Mumbai in India and an MSc (2006) in chemical engineering from Illinois Institute of Technology.

Steve Hendon ([email protected]) cofounded eSimulation Inc. in 2000 and has 30 years' experience in the development and implementation of real-time optimization and multivariable control projects for refining, petrochemicals, gas processing, and NGLs. Hendon holds a BSChE (1984) from the University of Oklahoma and is a member of the Gas Processors Suppliers Association.

Mark Roop ([email protected]) cofounded eSimulation in 2000 and has more than 30 years' experience in advanced automation and optimization, primarily in applications and business development. He has worked for Aspen Technology, Honeywell, and Emerson. Roop holds a BSChE (1981) from West Virginia University and is a member of the Gas Processors Suppliers Association.