Refinery fence-line monitoring to impact petrochemical operators

Gary Daves

Providence Engineering & Environmental Group LLC, Houston

US Environmental Protection Agency's (EPA) upcoming compliance deadline for refiners to measure and report ambient benzene concentrations at their fence lines will put petrochemical manufacturers with operations in close proximity to these refineries at risk for increased scrutiny and enforcement action.

Although EPA's "Petroleum Refinery Sector Risk and Technology Review and New Source Performance Standards" (RTR) rule covers only sources subject to refinery maximum achievable control technology (MACT) regulations, the rule's fence-line monitoring provisions require refiners to collect samples that represent fence-line ambient benzene concentrations, which can include contributions from petrochemical units both on and off a refinery's property (OGJ, Oct. 5, 2015, p. 40).

In promulgating the rule, EPA acknowledged these potential contributions from sources not subject to Refinery MACT requirements and included specific provisions for refiners to exclude contributions from these near-field interfering sources (NFSs) when calculating a refinery's reportable ambient benzene concentration. To exclude these NFS contributions, however, a refiner must submit a site-specific, fence-line monitoring plan in which it individually identifies excluded NFSs as well as quantifies their likely contributions to the refinery's ambient benzene concentrations.

Given that refining and petrochemical operations frequently are sited in the same general part of a city or region, petrochemical plants inevitably will be targeted as primary NFSs of benzene concentrations excluded by nearby refineries.

This article explores potential air-permitting and enforcement implications of the refinery RTR rule's fence-line monitoring requirements on petrochemical operations as well as considerations for operators that may be identified as NFS in refinery site-specific fence-line monitoring plans.

Rule background

The 1990 US Clean Air Act (CAA) amendments require EPA to address emissions of hazardous air pollutants (HAPs) from stationary sources under a two-stage regulatory process. In the first stage, EPA must identify categories of sources emitting one or more HAPs listed in CAA Section 112(b) and promulgate technology-based national emission standards for hazardous air pollutants (NESHAPs) for those identified source categories pursuant to CAA Section 112(d). For major sources-those that emit or have the potential to emit at least 10 tons/year (tpy) of a single HAP or 25 tpy of any combination of HAPs-the technology-based NESHAPs have been commonly referred to as MACT standards.1

After promulgating a MACT standard, EPA is required to review the technology-based standard and revise it "as necessary (taking into account developments in practices, processes, and control technologies)" no less often than every 8 years.2 Within 8 years of promulgating the technology-based standard, EPA "must evaluate the risk to public health remaining after application of the technology-based standards and revise the standards, if necessary, to provide an ample margin of safety to protect public health or to prevent (taking into consideration costs, energy, safety, and other relevant factors) an adverse environmental effect."3

Pursuant to the technology and residual risk reviews required by the second stage of the regulatory process, EPA published a proposed refinery RTR rule in the Federal Register on June 30, 2014.4 The final RTR rule was published in the Federal Register on Dec. 1, 2015, and became effective Feb. 1, 2016.5

Among other requirements, the RTR rule established a benzene fence-line monitoring work practice standard with an initial compliance date of Jan. 30, 2018, for existing sources.6 The fence-line monitoring provisions were incorporated into Title 40 of the Code of Federal Regulations (CFR) Part 63, Subpart CC (the Refinery MACT 1 standard) and EPA Reference Methods 325A and 325B.7 As such, these monitoring provisions are subject to Subpart CC applicability criteria (covering HAPs originating from on-site noncombustion or evaporative sources, including equipment leaks, tanks, wastewater, miscellaneous process vents, heat exchange systems, and cooling towers).

Because Refinery MACT 1's Subpart CC provisions specifically exclude process units and emission points subject to 40 CFR Part 63, Subparts F, G, H, and I-collectively the Hazardous Organic NESHAPs (HON)-and ethylene processes,8 these sources are not directly subject to fence-line monitoring requirements.

Closer examination of the range and nature of benzene-concentration data to be collected, however, suggests a refinery's seemingly exempted on-site units could be impacted as easily as neighboring petrochemical operations by the monitoring program.

Fence-line monitoring provisions

The RTR rule's fence-line monitoring provisions require sampling conducted in accordance with Methods 325A and 325B or an approved alternative test method.9 Method 325A includes instructions for how to set up the sampling network as well as placement and collection of sample tubes. Method 325B is the companion laboratory analysis method.

This article is based on using Methods 325A and 325B for fence-line monitoring because the refinery RTR regulatory package explicitly details requirements for both methods. Monitoring results from an approved alternative test method would have to be deemed equivalent and likely would have similar implications for nearby petrochemical plants.

Key aspects of Refinery MACT 1's fence-line monitoring provisions are as follows:

• Benzene is the target analyte.10

• The number of monitoring locations and their placement are determined by Method 325A procedures based on the refinery's size (either acreage or perimeter length) and configuration, including shape of the refinery property and whether "known sources of volatile organic compounds" (defined as a wastewater treatment unit, process unit, or any emission source requiring control according to the requirements of 40 CFR Part 63, Subpart CC, including marine vessel loading operations) are near the property boundary.11

• Pursuant to Method 325A, passive collection of the target analyte is accomplished with diffusive sorbent tubes placed under weather protectors.

• The sampling period is 14 days unless a shorter sampling period is deemed necessary under a site-specific monitoring plan or a root-cause analysis triggered by the rule's benzene concentration-based action level.12

• For each sampling period, a benzene concentration, Δc, is determined using either the default procedure for calculating Δc (as the difference between the highest and lowest benzene concentrations from the samples collected) or a site-specific monitoring plan.13

• For each sampling period, a new annual average Δc is calculated from the 26 most recent sampling-period Δc values.14

• An action level of 9 μg/cu m (2.8 parts per billion by volume, ppbv), on an annual average basis, triggers the rule's root-cause analysis and corrective action procedure.15

• After collecting the first 12 months of fence-line monitoring data, the refinery submits the initial and all subsequent data on a quarterly basis to EPA's Compliance and Emissions Data Reporting Interface (CEDRI), through the agency's Central Data Exchange (CDX).16

While listed refinery fence-line monitoring provisions do not apply directly to the petrochemical industry, the refinery fence-line monitoring sampling results have both near-term and potentially long-term implications for petrochemical sources.

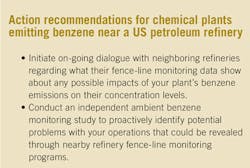

The accompanying box lists immediate recommendations for owners-operators of petrochemical sites to consider ahead of the refinery fence-line monitoring compliance deadline.

Near-term concerns

If the refinery owner or operator believes an off-site upwind source or an on-site source excluded under 40 CFR 63.640(g) (e.g., ethylene processes or HON processes and emission points) may influence the benzene measurements, fence-line monitoring requirements provide for collection of background samples through a site-specific monitoring plan developed and submitted by the refinery owner or operator to EPA for approval.17

The refinery fence-line monitoring reporting provisions require the refiner to submit individual "sample results for each monitor for each sampling period" to ensure the total ambient benzene concentration measured at each sampling location will be reported for each 14-day sampling period.18 Since EPA requires refiners to identify NFSs in their site-specific monitoring plans,19 on-site and off-site petrochemical sources contributing to high ambient benzene concentrations will be implicated.

Many states have air toxics programs with ambient benzene concentration thresholds in either regulatory or policy form. Because air quality permit representations can be binding, regulators and environmental interest groups can compare ambient benzene concentrations attributed to petrochemical operations under the RTR rule's fence-line monitoring program to required air dispersion modeling results previously submitted to state air toxics programs. If the measured ambient concentrations exceed the modeled ambient concentrations, a petrochemical plant's owner-operator, at a minimum, may be subject to intensified scrutiny by local, state, or federal regulators or other interested parties, and could face EPA enforcement actions to determine whether the site's emissions were accurately represented in air quality permit applications. Since refineries' fence-line monitoring data will be publicly available, environmental groups, media outlets, and the public seeking some context for the reported benzene concentrations also likely will use ambient benzene thresholds from state air toxics programs as a convenient reference point.

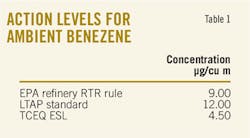

Some states' ambient benzene thresholds are close to EPA's fence-line monitoring action level of 9 μg/cu m (2.8 ppbv). For example, Louisiana and Texas-two states with a high concentration of refineries-have annual benzene ambient thresholds easily comparable to fence-line monitoring results.

The Louisiana Toxic Air Pollutant (LTAP) standard for ambient benzene is 12.00 μg/cu m (annual basis).20 The Texas Commission on Environmental Quality's (TCEQ) Effects Screening Level (ESL) for benzene of 4.5 μg/cu m (annual average),21 meanwhile, is half of EPA's 9-μg/cu m fence-line monitoring action level.

The accompanying table compares the federal, Louisiana, and Texas action levels for ambient benzene concentrations.

In Texas, reported ambient concentrations that fall well below the federal fence-line monitoring action level could still garner attention if they simply exceed the state's ESL. As a result, petrochemical sources contributing to those ambient concentrations also may find themselves under heightened scrutiny.

Even if the cause of a high benzene concentration is found to be a source in compliance with all applicable state and federal control technology (e.g., MACT) standards, enforcement actions could result if that concentration exceeded air permit emission limits and representations submitted as part of an air quality permit application, including air dispersion modeling submittals.

EPA or state agency enforcement actions under the refinery RTR rule could include the following:

• Financial penalties.

• Additional emissions controls.

• Additional permit (e.g., operational) limitations or requirements.

• Inconvenience and cost of having to update air quality permit emission rates.

Increased scrutiny resulting from the fence-line monitoring program also could lead to discovery of compliance issues that may have otherwise been unknown to the plant's owner-operator but will nonetheless require additional investments of time, labor, and money to remedy.

Alongside issues associated with state ambient benzene thresholds are potential concerns regarding public perception of ambient benzene concentrations reported to be above EPA's fence-line monitoring action level at individual locations. While EPA classifies the fence-line monitoring requirement as a "work practice standard" (vs. a type of emissions limit), the distinction that the benzene concentration threshold of 9 μg/cu m (2.8 ppbv) serves as an action level rather than an emissions limit may not be fully recognized or understood when EPA makes monitoring data publicly available. Plant owner-operators also should expect the public to make a variety of comparisons among refineries and petrochemical sources as a group as well as between individual plants.

Immediate considerations

While operators can defer reporting refinery fence-line monitoring data to EPA until 12 months of data have been collected, data from the initial and all subsequent sampling periods must be reported. Consequently, publicly available data will document high benzene concentrations from any issue resulting in high benzene emissions from a petrochemical source, even if that issue was identified and corrected soon after the monitoring compliance date.

Unless a specific, recent change can be identified as a cause of the high benzene concentration, the presumption likely will be that the condition was a long-standing one, entailing all enforcement and potential legal implications that normally accompany that presumption.

To avert potential problems that could arise from discovery of high benzene concentrations at a refinery's fence-line, many refiners are conducting benzene fence-line monitoring studies to identify potential issues and take corrective action this year, ahead of EPA's Jan. 30, 2018, data-collection compliance date. Several more have conducted benzene fence-line monitoring studies in the past.

It is advisable for petrochemical plants operating near a refinery to initiate discussions with the neighboring refinery to determine whether benzene emissions from the petrochemical operations could be implicated as a contributor to a high benzene concentration at the refinery's fence line. Depending on whether the refinery has performed an ambient benzene monitoring study, what the data indicate, and how much information the refinery is willing to share with the nearby petrochemical plant, it also may be advisable for the petrochemical operator to conduct its own ambient benzene monitoring study to determine whether the site could be implicated as a cause for a high ambient benzene concentration reported by the refinery in the future.

Seasonal and even day-to-day variations in wind direction as well as a petrochemical plant's benzene emissions can affect the extent to which a neighboring plant's emissions would impact a refinery's fence-line benzene concentrations.

Figs. 1-4 show summaries of variations in wind directions observed for four different 15-day periods over the past year at Houston's William P. Hobby Airport.

Given the variability of wind patterns as well as the close proximity of refining and petrochemical operations in regions like the US Gulf Coast, petrochemical plant owners-operators in these areas can reduce exposure to potentially adverse impacts arising from the RTR rule's fence-line monitoring program by starting studies as early as possible to collect the maximum amount of data before the Jan. 30, 2018, compliance date, at which time refineries will be required to report collected fence-line benzene monitoring data to EPA and, ultimately, the public.

Long-term concerns

Though less well-defined than near-term concerns, long-term implications for petrochemical industry sources that could result from the refinery fence-line monitoring program are equally important.

The potential for petrochemical contributions to refinery fence-line benzene concentrations as reported to EPA by refineries could affect future rulemaking at the federal, state, or local level by highlighting petrochemical benzene emissions. Additional rulemaking could require further emissions controls or work-practice standards, even for sources already subject to MACT standards.

Speculation also continues to grow in the petroleum industry that EPA will add fence-line monitoring requirements for additional industrial sectors through the MACT RTR process. Any additional emissions control technology and work-practice standards for a sector that includes fence-line monitoring for petrochemical sources eventually would require affected plant owners-operators to invest in corrective actions at their sites.

Petrochemical plant owners-operators that immediately implement current refinery fence-line monitoring guidelines to understand and resolve potential issues at their sites will do so at lower costs and with greater efficiency than those delaying action until enforcement under future-and likely more stringent-EPA rulemakings.

References

1. "Petroleum Refinery Sector Risk and Technology Review and New Source Performance Standards; Proposed Rule," Federal Register, Vol. 79, No. 125, June 30, 2014, p. 36883.

2. US Clean Air Act (CAA), Title I, Pt. A, Section 112(d)(6).

3. "Petroleum Refinery Sector Risk and Technology Review and New Source Performance Standards; Final Rule," Federal Register, Vol. 80, No. 230, Dec. 1, 2015, p. 75180.

4. 79 FR 36879.

5. 80 FR 75178.

6. US Code of Federal Regulations (CFR) Title 40, Pt. 63, Subpart CC, Appendix, Table 11.

7. 40 CFR 63, Appendix A.

8. 40 CFR 63.640(g).

9. 40 CFR 63.658(a).

10. 40 CFR 63.658(b).

11. 40 CFR 63.658(c)(1).

12. 40 CFR 63.658(e)(1).

13. 40 CFR 63.658(f)(1).

14. 40 CFR 63.658(f)(2).

15. 40 CFR 63.658(f)(3).

16. 40 CFR 63.655(h)(8).

17. 40 CFR 63.658(c)(2).

18 40 CFR 63.655(h)(8).

19. 40 CFR 63.658(i)(1)(i).

20. Louisiana Administrative Code (LAC) Title 33, Pt. V, Chapter 51, Table 51.2.

21. "Effects Screening Levels List," Texas Commission on Environmental Quality (TCEQ), November 2016, https://www.tceq.texas.gov/toxicology/esl/list_main.html.

The author

Gary Daves ([email protected]) is technical services director of air quality for Providence Engineering & Environmental Group LLC, Houston, where he manages Refinery Sector RTR rule fence-line monitoring studies for 11 refineries. Daves has 19 years of experience assisting clients with regulatory compliance, including regulatory applicability determinations, performing compliance audits, and Title V and New Source Review permitting for petroleum refineries and petrochemical plants. He holds a BS (1993) from the University of Arkansas and MS (2005) from Georgia Tech, both in mechanical engineering, and is a licensed professional engineer in Louisiana.