Kuwait’s new Al-Zour refinery enters commercial operation

Kuwait Petroleum Corp. (KPC) subsidiary Kuwait Integrated Petroleum Industries Co. (KIPIC) has officially commissioned the first phase of its long-planned, grassroots 615,000-b/d Al-Zour integrated refining and petrochemical complex in southern Kuwait, about 90 km south of Kuwait City (Fig. 1).

Following a series of delays since beginning construction in 2015, the refinery entered commercial operation in early November 2022 after startup of the complex’s associated LNG import terminal earlier in the year.

Al-Zour refinery is the cornerstone of Kuwait’s recently completed Environmental Fuel Project (EFP; formerly Clean Fuels Project) to upgrade and expand overall capacity of its refineries to produce clean-burning fuels conforming to Euro 5 standards. Its commissioning comes as part of KPC’s broader downstream program under its 2030 strategy to ensure a stable supply of clean fuels produced from Kuwaiti crude to its domestic consumer and industrial markets, as well as to enhance growth of the country’s refining and manufacturing sectors on a global scale.

In addition to presenting an overview of the Al-Zour refinery, its known technologies, and KIPIC’s plan for future petrochemicals production at the site, this article briefly discusses the complex’s associated LNG import terminal.

Al-Zour overview

First approved in 2011 but without engineering contracts awarded until 2015, the Al-Zour refining project was planned from inception to replace Kuwait’s outdated and now-shuttered 200,000-b/d Shuaiba refinery under the EFP. In addition to building the new refinery, EFP included a program to upgrade, expand, and transform Kuwait National Petroleum Corp.’s formerly 270,000-b/d Mina Abdullah and 466,000-b/d Mina Al Ahmadi refineries into an integrated 800,000 b/d merchant refining complex (OGJ Online, Jan. 6, 2020).

Covering a total project area of about 16 sq km, the KIPIC-operated Al-Zour complex consists of the 615,000-b/d refinery—now the world’s largest—future petrochemical production installations, and the already operating LNG Import Permanent Facilities Project.

Built adjacent to an artificial island for liquid-products storage with capacity of 5.6 million bbl, used to maintain strategic fuel stocks for different seasons and needs, the refinery will also eventually include a pier about 3 km offshore to accommodate exports of sulfur solid products via ships with a maximum payload of up to 60,000 tonnes (Fig. 2). The complex additionally hosts an 88-reservoir depleted field with combined crude storage capacity of 15 million bbl.

In addition to supplying cleaner fuels, the refinery also features advanced efficiency and environmental controls, including:

- An electronic monitoring and control network system to achieve better management, monitoring, analysis, and reporting of processes and activities.

- Multiple sulfur recovery units (SRU) designed to stabilize production processes and provide required environmental specifications.

- Permanent emission control systems in high-capacity combustion equipment.

- A permanent ambient air-quality control system.

- A flare gas-recovery system to reduce burners to minimum levels.

- A ground flaring system that employs smokeless, reduced-noise flares.

- A wastewater recycling system that enables the refinery to treat and reuse water during normal operations in lieu of discharging it.

At an overall cost of about 4.87 billion dinar ($16.2 billion) and representing 46% of total Kuwaiti refining capacity, the Al-Zour refinery—which employs about 1,000 people—is Kuwait’s largest petroleum-related undertaking, forming a cornerstone of the country’s future economic development and that of its oil sector, KIPIC and Kuwait’s Ministry of Oil (MOO) said.

The Al-Zour refinery exported its first shipment of jet fuel on Nov. 27, 2022, with a first shipment of naphtha produced at the site having loaded for export just days earlier, MOO said in separate releases.

Refinery units, technologies

The Al-Zour refinery was designed in the form of three main plants, or mini-refineries, to ensure and enhance operational reliability. Each mini-refinery contains an atmospheric crude distillation unit (CDU), a residual oil desulfurization unit, and a hydrogen treatment unit for diesel, naphtha, and kerosine, making it the largest complex of desulfurization units in the world.

Each of the plants is connected to central services units such as tanks and support installations, including gas collection units, hydrogen production units, hydrogen extraction units, pressurizing units, SRUs, and associated utility units.

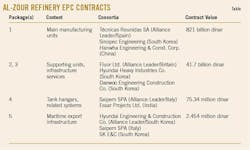

Implemented under five main engineering, procurement, and construction (EPC) packages awarded in 2015 to four international consortia, the refinery reached mechanical completion in phases between 2020 and 2022, with commissioning activities initiated in May 2022 (see accompanying table).

- 3 crude distillation units, each with a processing capacity of 205,000 b/d.

- 3 atmospheric residue desulfurization units, each with a processing capacity of 110,000 b/d.

- 3 diesel hydrotreating units, each with a processing capacity of 62,000 b/d.

- 2 18,200-b/d naphtha hyrdrotreating units.

- 2 kerosine hydrotreating units, each with a processing capacity of 53,000 b/d.

- An 8,500-b/d saturated gas unit.

- A heavy oil cooling unit.

KIPIC in 2018 awarded a contract to DuPont Clean Technologies to supply its proprietary technology licensing and design for a 9,100-b/sd STRATCO alkylation unit as well as a 70-tonne/day MECS advanced sulfuric acid regeneration (SAR) unit, both of which will enable the refinery to fulfill its targets for desulfurization and reduced emissions. The STRATCO alkylation unit was to feature Dupont’s Contactor XP2 technology in the STRATCO Contactor reactors, a patented reactor enhancement that maximizes use of the tube-bundle heat transfer area to ensure high-quality alkylate product from methyl tertiary butyl ether raffinate feedstock.

In October 2022, MOO said the refinery also would include unidentified process technologies from Chevron Lummus Global, Shell PLC’s Shell Global Solutions, Topsøe AS, and Fluor Ltd.

Petrochemicals’ future

Alongside refining operations, a critical portion of the Al-Zour project will involve implementation of petrochemical production capacity at the complex as part of KIPIC’s proposed Petrochemical Refinery Integration Al-Zour Project (PRIZe), which is designed to upgrade fuel products from the refinery to high-demand bulk petrochemical products, including 2.761 million tonnes/year (tpy) of aromatics and polypropylene, as well as 1.7 million tpy of gasoline (OGJ Online, Nov. 14, 2019).

Intended to maximize value of Kuwait’s hydrocarbon products and increase gasoline supplies to the domestic market, the PRIZe project will, upon completion, increase Kuwait’s polypropylene and aromatics production by 1000% and 200%, respectively, from current levels, KIPIC said.

While no definitive timeline has been revealed for this second phase of the Al-Zour complex, MOO confirmed in June 2022 that front-end engineering and design (FEED) for PRIZe has been completed.

KIPIC previously awarded a contract to McDermott International Inc. to deliver basic engineering, technology licensing, and catalyst for an integrated low-pressure recovery (LPR) and olefins conversion technology (OCT) unit at the complex, which the service provider said would add a gasoline block, an aromatics block, OCT unit, polypropylene units, as well as associated utility and offsite installations to the existing refinery site.

In July 2019, KIPIC contracted Honeywell UOP LLC to revise the configuration and capacity of the refinery’s original gasoline production installations, as well as supply technology licenses, design services, key equipment, and catalysts and adsorbents to produce clean-burning fuels, paraxylene, propylene, and other petrochemicals as part of PRIZe (OGJ Online, July 26, 2019).

To accommodate PRIZe, the refinery’s gasoline section was reconfigured to include:

- A 98,000-b/d RFCC complex for production of propylene, gasoline, and petrochemical aromatics.

- A UOP Selectfining unit to produce low-sulfur gasoline blending components.

- Two UOP Merox units to treat propane for propylene production and isobutane to make clean-fuel blending components.

- An 11,800-b/d Butamer unit to convert normal butane to isobutane.

The petrochemicals section will consist of an aromatics complex capable of producing 1.4 million tpy of paraxylene using the latest generation LD Parex aromatics technology, including the Sulfolane, Isomar, and Tatoray processes.

The CCR Platforming unit and naphtha hydrotreater also was expanded from its initial design to meet the needs of the larger gasoline and aromatics complexes.

Honeywell UOP also provided an Oleflex propane dehydrogenation unit equipped to produce 660,000 tpy of polymer-grade propylene for the project.

LNG terminal overview

Part of the KPC’s long-term strategic direction to 2040 that includes a commitment to maximize use of natural gas to meet energy needs, LNG import terminal project became fully operable Feb. 21, 2022, MOO confirmed.

At an overall investment of $2.93 billion, the project is the world’s largest LNG import terminal in terms of storage capacity, featuring eight tanks each with a capacity of 225,000 cu m and using three low-pressure pumps.

Built by a consortium of Hyundai Engineering Co. Ltd., Hyundai Engineering & Construction Co., and Korea Gas Authority starting in 2016, the 3-billion btu/day import terminal includes two integrated offshore berths to simultaneously accommodate two tankers. The terminal also is equipped with a compression system for natural gas vapors produced during tank filling.

The import terminal received its first 213,000-cu m shipment of LNG from Qatar in July 2021, according to the MOO.

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.