Energy transition fuels Nacero’s plans for GTG plant in Texas Permian basin

In 2021, Houston-based Nacero Inc. confirmed it will build a natural gas-to-gasoline (GTG) plant in Penwell, Ector County, Tex., 8 miles west of Odessa, in the heart of the Permian basin (OGJ Online, Apr. 22, 2021).

To be powered by 100%-renewable energy, the proposed $6.5-7.5-billion Penwell GTG plant will be the first in the US to produce potentially net-zero lifecycle carbon-footprint gasoline from natural gas and renewable natural gas, as well as the first in the world to incorporate carbon capture and sequestration (CCS).

Slated to become the flagship in a series of similar plants Nacero is developing to advance its own and US domestic climate-change mitigation goals in support of the global energy transition, the Penwell plant is scheduled for start of its phased construction during first-half 2022 following Nacero’s recent regulatory approval to proceed with the project and award of major contracts for related works.

This article presents an overview of current plans for the proposed Texas GTG plant, including selection of process technology, the types of finished products to be produced, as well as the operator’s approach to delivering sustainably produced fuels to domestic drivers at competitive prices.

Project, technology overview

Set on 2,600 acres in Penwell, Nacero’s planned Penwell GTG complex will use a feedstock mix of natural gasoline, biomethane captured from farms and landfills, and mitigated flare gas currently emitted from the Permian basin to produce low-carbon, zero-sulfur finished gasoline component ready for blending to US commercial grades (Fig. 1).

Scheduled for a 4-year construction period, Phase 1 of the plant will produce 70,000 b/d. The second phase of construction, which will take an additional 2 years, will bring the Penwell plant’s total capacity to 115,000 b/d.

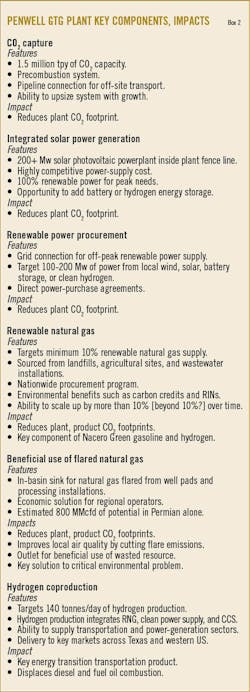

Following announcement of the project in April 2021, Nacero let a contract to Haldor Topsoe AS to deliver licensing of its proprietary Topsoe Improved Gasoline Synthesis (Tigas) GTG technology for the grassroots plant. The Penwell Tigas unit—which will incorporate six Topsoe proprietary SynCOR Methanol autothermal reforming units—also will enable the planned GTG plant to produce more than 30,000 tonnes/day of methanol for further processing into zero-sulfur, cost-competitive gasoline, leaving Nacero only a byproduct of purified water that, in turn, will be recovered and used to supply 80% of the plant’s makeup water, the companies said in separate releases.

Use of Tigas technology will enable the GTG plant to cut both the production cost and lifecycle carbon footprint of everyday transportation fuel by 50% compared with traditional, petroleum-derived fuel, as well as eliminate 1 billion tonnes of carbon dioxide (CO2) emissions during its first 30 years of operation, according to Nacero.

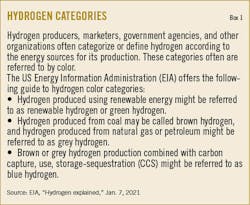

Nacero said the Penwell GTG plant will receive all its electricity from renewable sources, much of which will be produced on-site from solar panels co-located with its processing and production installations, which will include blue hydrogen (see Box 1).

Sequestered CO2 captured by the plant’s 1.5-million tonne/year (tpy) CCS system will be transported via an existing on-site pipeline for use in enhanced oil recovery operations.

Upon completing its scope of work on front-end engineering design (FEED) for the Penwell GTG plant, Bechtel Corp. said it would also deliver a lump-sum turnkey price proposal for engineering, procurement, and construction (EPC) of the project (OGJ Online, May 27, 2021).

Following the Texas Commission on Environmental Quality’s approval of an air quality permit authorizing construction and operation of the project in late-November 2021, Nacero said in mid-February 2022 it planned to break ground on the Penwell GTG plant by the end of first-quarter 2022. As of end-March 2022, however, Nacero confirmed to OGJ groundbreaking will take place during first-half 2022.

Products, process overview

Designed specifically to convert Permian natural gas into gasoline blendstock and mixed LPGs for production of sulfur-free gasoline without additional costs to consumers or by-products associated with traditional crude oil refining, Nacero’s energy transition-based production process will yield two primary products: Nacero Blue and Nacero Green gasolines.

To be made from a feedstock of natural gas using renewable power and CCS, Nacero Blue will be most cost-competitive with traditional gasoline and will enable drivers to reduce the lifecycle carbon footprint of their car or truck’s fuel by half. Nacero Green—which will be produced from a combination of purchased volumes of renewable natural gas and captured flare gas—will offer the potential to reduce the lifecycle carbon footprint of a vehicle’s fuel all the way to zero or below, the operator said.

The plant’s production of Nacero Blue, Nacero Green, and blue hydrogen will involve several major steps.

After receiving its primary feedstock of natural gas—produced off site—via a high-capacity pipeline, the plant will convert the gas to syngas by breaking it down into its constituent molecules of hydrogen and carbon monoxide.

While excess hydrogen will be stored on-site for later sale into the market, syngas volumes will be catalytically converted into methanol, which in turn will be catalytically converted into gasoline molecules, releasing water in the process.

The resulting gasoline blendstock will be combined with ethanol and other additives to achieve retail-grade specifications, after which it will be transported to market via pipeline, rail, and truck.

Nacero said it will apportion its production of Nacero Green gasoline based on the amount of renewable natural gas purchased for the plant, with all other gasoline volumes to end up as Nacero Blue.

Excess hydrogen yielded from the plant’s production process and stored on site for later sale to the market will be delivered to end users via truck, the company said.

Fig. 2 shows an overview of the Penwell GTG plant’s proposed layout.

Box 2 presents key features and anticipated impacts of the plant’s major components.

Major power-supply contract

Most recently, Nacero in mid-February 2022 awarded a contract to NextEra Energy Resources LLC to supply the Penwell GTG plant with nearly 20 billion kw-hr of green electricity across a 20-year period starting in 2025.

Nacero said the wind power-supply agreement—a key component of the Penwell project—will complement the operator’s own planned 200-Mw solar photovoltaic power plant to be built on site to help ensure the Penwell GTG plant remains powered by 100% renewable electricity.

Future plans

In addition to the Penwell GTG plant, Nacero previously entered agreements with Haldor Topsoe to supply its proprietary process technology and catalysts for use in the operator’s other proposed US GTG plants, which currently include potential projects in Arizona and Marcellus basin in Pennsylvania (OGJ Online, Mar. 26, 2020).

Details regarding the status of development for either the Arizona or Pennsylvania projects have yet to be revealed.

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.