Pinch analysis spots design retrofits to support Aramco unit upgrades

Zeeshan Farooq

Sami Almutairi

Saudi Aramco

Dhahran

Saudi Aramco recently executed a study based on pinch analysis techniques to examine and improve heat integration of the vacuum distillation unit (VDU) at Saudi Aramco Base Oil Co.’s (Luberef) 1-million b/d base oils refinery in Yanbu, Saudi Arabia.

Using a combination of pinch analysis and software simulations based on unit operating data, the energy optimization study identified opportunities for low-cost retrofits and additions to the VDU’s heat exchanger network (HEN) design that, if implemented, could reduce the unit’s overall fuel gas consumption to improve its overall efficiency, production, and environmental performance.

Alongside offering a more than 10% internal rate of return (IRR), the study’s proposed retrofitting projects ensured potential modifications included to improve near-term performance of the site would complement rather than impede future retrofitability to remain environmentally compliant and competitive.

This article, the second of two, describes the study’s recommended near-term and future modifications to the VDU’s HEN, discusses equipment considerations, and provides a brief overview of project economics.

The first article discussed Aramco’s objectives and methodology for the energy optimization study, providing a detailed overview of the Yanbu VDU and HEN configurations as well as an in-depth overview of the pinch analysis approach (OGJ, Jan. 3, 2022, p. 41).

Simulation, data extraction

Aramco built the primary simulation model for the study from all relevant VDU-HEN operating data (flow rates, temperatures, pressures across different time intervals, and yearly average production and processing rates) provided directly by the Yanbu plant’s historian.

Initial analyses showed potential heat-recovery was possible in the HEN’s B-1001 fired-heater HEN (used for feed preheating), as data indicated heat was being wasted in the tempered-water system and air coolers. To conduct pinch analysis for minimizing the B-1001 heat utility, Aramco extracted specific data for related VDU cold (those to be heated) and hot (those needing to be cooled) streams (Table 1).

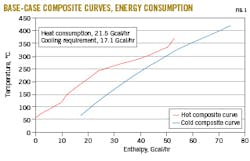

Based on its pinch analysis of the cold-hot stream data using separate hot and cold composite curves, Aramco identified an existing VDU HEN ∆Tmin of 34° C., with corresponding hot and cold utilities load demands of 21.53 Gcal/hr and 17.13 Gcal/hr, respectively (Fig. 1).

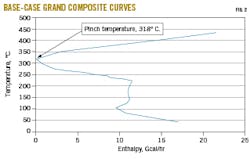

Extracted data also enabled creation of a grand composite curve (GCC), or heat surplus diagram, to help identify minimal-cost utilities as well as potential for steam production, use of surplus system power, and special-equipment integration opportunities for use in the base case (Fig. 2).

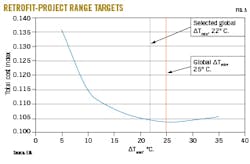

To identify an optimum ∆Tmin for the retrofit base case, Aramco conducted a range analysis, using available energy data from the plant to estimate an operating and capital cost index as well as a projected project cost (Fig. 3). Based on the minimum total cost index, the analysis indicated an optimum ∆Tmin of 25° C. Considering the existing HEN design was not created using pinch-analysis principles, however, Aramco selected a lower ∆Tmin of 22° C. for the retrofit. Based on heat-recovery principles as well as its analyses of the existing system’s temperature and area efficiency, the team determined the lower ∆Tmin will require higher investment but will result in increased long-term energy savings.

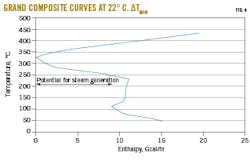

Based on GCCs created for the target ∆Tmin of 22° C., Aramco selected hot and cold utilities load targets of 19.5 Gcal/hr and 15.1 Gcal/hr, respectively (Fig. 4). At these levels, analyses showed Yanbu could reduce heater firing by about 2.0 Gcal/hr and use steam generation as cold utility given the high pitch temperature (Fig. 2).

Network modifications

Aramco’s combination of pinch analysis and simulations led to a series of determinations to help guide proposed configurations to the VDU’s HEN:

- The VDU’s HEN could reduce heating duty by about 6.6 Gcal/hr by recovering rejected or wasted process heat.

- Furnace duty could be reduced by an overall 2 Gcal/hr resulting from a 21.2° C. temperature increase of feed streams to B-1001. This could be achieved through small modifications to the feed circuits, the third pumparound (PA 3), and excess overflash streams, as well as the addition of four new heat exchangers to the preheating train.

- In addition to process-to-process heat recovery, Yanbu could generate medium-pressure (MP) and low-pressure (LP) steam by using 4.6 Gcal/hr of heat available from the vacuum residue stream.

Since the proposed modifications maintain all current column-return temperatures, the VDU column temperature profile and product temperatures (inside battery limits) would no longer impact process operations at the plant following the revamp.

As part of creating the proposed retrofits, Aramco also performed a separate hydraulic study to validate capabilities of the VDU’s hydraulic system. This study stemmed from amplified pressure drops observed on a few product pumps subsequently determined to be caused by additional exchangers on feed and product circuits.

Base case

The material balance conducted as part of the study aligned very closely to actual plant data and was found to be well within acceptable engineering limits (1-2% maximum) for VDUs. The study’s heat balance executed on the plant demonstrated crude moving from storage to the VDU column (T-1001) required a heating duty of about 57.3 Gcal/hr, of which the HEN’s B-1001 feed preheater has a share of around 35.8 Gcal/hr (62.5%), with furnaces rendering the leftover 21.5 Gcal/hr (37.5%). The study’s primary objective, then, was to modify heat integration capabilities of the existing HEN by upgrading preheating operations to diminish necessary furnace duties during normal operations and reduce fuel gas consumption.

Fig. 5 shows the base case for proposed modification of the VDU HEN area.

Based on its analyses, Aramco determined the HEN’s B-1001 fired heater is the system’s only hot utility requiring an additional exchanger or an area manipulation to improve heat integration.

While it is not advisable to minimize fired-heater duty by using high-pressure (HP) steam, steam generation can be used to reduce the burden of utility generation to help cut overall on-site energy consumption. In this case, the team considered steam generation as a solution since the Yanbu refinery includes HP, medium-pressure (MP), and low-pressure (LP) levels of steam utility.

First proposed retrofit

The first modification recommended by the study includes installation of a heat exchanger (HE-1) after the E-1009 C heat exchanger, between the excess overflash stream and the feed stream (Fig. 6).

Since addition of HE-1 will reduce driving force in the E-1007 A/B exchanger and requires additional area as compensation for that reduction, however, the study recommended installation of a second new heat exchanger (HE-2).

This first proposed modification will reduce heating duty of B-1001 by about 1.0 Gcal/hr.

While the study confirmed feasibility of the proposed modification with the addition of both HE-1 and HE-2, during execution, the team also proposed the alternative of evaluating possibilities for improving performance of the existing E-1007 A/B heat exchanger by enhancing its overall heat-transfer coefficient. Based on preliminary evaluations, it might be possible to achieve the required additional duty from E-1007 A/B by adding a twisted-tube bundle or altering the number of passes, which could eliminate the need of installing HE-2.

Eliminating the addition of HE-2 will result in higher-than-estimated savings and would reduce duration of the project.

Second proposed retrofit

The second proposed modification suggested by the study involves installation of a new heat exchanger (HE-3) between the feed stream before the E-1009 A/B exchanger and the residue stream after the E-1008 A/B exchanger (Fig. 7).

Since installation of HE-3 will reduce the driving force in the E-1009 A/B/C exchanger, the study recommended installation of another new exchanger (HE-4) to make up for the reduction.

While these modifications would further require enhancement of the area to avoid impacts on the proposed HE-1, the study’s proposed modifications were specifically developed to accommodate future recommended retrofits. As such, both proposed retrofits could be executed easily using identical shells.

This second proposed retrofit involving installation of HE-3 and HE-4 will further reduce heating duty of B-1001 by about 1.0 Gcal/hr to achieve the study’s recommended required fired-heater targets at the ΔTmin of 22° C.

Further enhancement should be directed toward energy steam generation.

Third modification

Focused on improving energy efficiency via steam generation, the study’s third proposed modification plan involves installation of new consecutive MP and LP steam generators ahead of the existing E-1016 A/B exchanger to extract energy from the residue stream (Fig. 8).

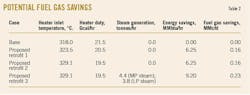

This third proposed modification will recover about 2.5 Gcal/h of energy for MP steam generation and about 2.1 Gcal/h of energy for LP steam generation, resulting in about 4.4 tonnes/hr of MP steam and 3.8 tonnes/hr of LP steam. Based on the plant-wide combined heat and power model created for the study, collective MP and LP steam generation provided by this modification will reduce Yanbu’s overall estimated fuel gas requirements by about 9.2 MMbtu/hr.

Future retrofit potential

Based on a combination of traditional design techniques used for HEN retrofits to ensure ease of future modification works, Aramco’s new retrofit-with-retrofit-in-mind approach used for the study recommended retrofits that could be executed in phases to solve current issues but would not pose barriers to revamp initiatives that may be required across the plant’s lifetime.

As a result of the retrofit-with-retrofit-in-mind approach, the study’s three proposed retrofitting plans include different routes for attaining near-term HEN energy consumption targets while planning for future plant retrofitability.

The study’s three proposed retrofitting projects have been chosen to pave the way for future modification projects to improve HEN efficiency relating to LP steam generation and makeup-water heating (qualitatively noted in red on Fig. 9).

Results, project economics

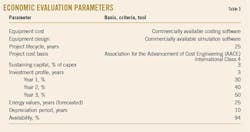

With implementation of all three proposed retrofits, Aramco estimates a 21.7-MMbtu/hr (0.54-MMcfd) reduction in Yanbu’s total consumption of fuel gas, resulting in a net present value (NPV) of $9.1 million and an average internal rate of return (IRR) of about 11% (Tables 2-3).

As noted above and in the first article, however, adoption of certain alternative modifications proposed as part of the HEN retrofitability study could result in more intense energy savings, as well as in increased mitigation of greenhouse gas emissions that could further improve savings.

Equipment considerations

Aramco completed design of new heat exchangers proposed by the study using a commercially available heat exchanger design and rating software based on stream process data collected from the VDU plant’s simulation. The exchangers with finished designs were then connected with the VDU plant’s simulation rating model to imitate the influence of these new exchangers on the VDU preheat train.

The eight additional shells required for implementation of the three proposed retrofits have a combined surface area of 23,459 sq ft.

Table 5 presents design data and total installation costs for the newly proposed exchangers.

The authors

Zeeshan Farooq ([email protected]) is lead process optimization engineer at Saudi Aramco. With more than 20 years’ field experience in process integration, process modeling and simulation, energy optimization, process improvement, process engineering, and process development, he holds multiple patents in the field of sustainable energy efficiency design. Previously serving as a senior engineer for Dow Chemical Co. in India, Farooq holds a BS (1999) and MS (2002) in chemical engineering, both from Aligarh Muslim University, India.

Sami Almutairi ([email protected]) is a process optimization engineer at Saudi Aramco, where he specializes in process integration and energy optimization. A past recipient of the Young Energy Professional of the Year award from the Association of Energy Engineers, he holds a BS (2015) and MBA (2021), both from King Fahd University of Petroleum and Minerals, Saudi Arabia.