Post-Aliso Canyon regulations focus on natural gas storage reliability

Richard A. Schultz

The University of Texas at Austin

Donnie Vereide

Geostock Sandia LLC, Houston

A suite of new federal and California regulations went into effect in the wake of the Aliso Canyon, Calif., natural gas leak (Oct. 23, 2015-Feb 4, 2016). These regulations require operators of underground natural gas storage facilities to collate, archive, and distribute key information for regulatory compliance; manage geologically different facilities (e.g., porous-rock storage vs. salt cavern storage) consistently across an operator's asset portfolio; and demonstrate risk-reduction progress over time.

New federal regulations are already in place for all intrastate and interstate underground natural gas storage (UGS) sites. The Interim Final Rule (IFR)1 released Dec. 19, 2016, by the US Pipeline and Hazardous Materials Safety Administration (PHMSA) applies an initial set of common minimum standards (based on API RP 1170 and 1171) with which all operators will be expected to comply.

The IFR's goal is to increase reliability of the combined transport (pipeline) and storage system. Many of the provisions parallel those proposed by PHMSA in April 2016 to strengthen pipeline reliability, including coverage-area expansion, prescriptive data gathering and integration, risk assessment validation, mechanical and corrosion integrity validation, recordkeeping expansion, and change management (OGJ, Nov. 7, 2016, pp. 69-73 and OGJ, Dec. 5, 2016, pp. 70-74). A holistic asset integrity management system can therefore help underground storage operators meet the impending requirements.

Regulatory environment

There are about 197 underground natural gas storage sites connected to interstate pipeline systems and 203 connected to intrastate pipelines.1 PHMSA administers the national regulatory program to ensure the safe transportation of natural gas and other hazardous materials by pipeline. It defines minimum federal standards that apply directly to interstate pipeline systems and, via state agencies, to intrastate pipelines. Permitting of interstate systems is administered by the Federal Energy Regulatory Commission (FERC), with the states permitting their intrastate systems. The Natural Gas Pipeline Safety Act of 1968 gave PHMSA authority over underground natural gas storage, but the agency declined to develop regulations until last year.2

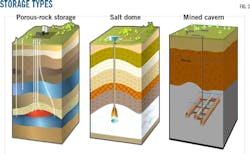

As a response to the intrastate Aliso Canyon event, as well as other UGS leaks since 2001 noted in the IFR, the US Congress passed the PIPES Act,3 requiring PHMSA develop and deploy safety standards for underground natural gas storage sites (Fig. 1). Interstate sites would be covered directly, while intrastate storage locations would be expected to meet the new federal minimum standards plus any imposed by that particular state in a certification process analogous to that for pipeline systems.

IFR, RPs

PHMSA's IFR incorporated by reference two American Petroleum Institute (API) recommended practices: API RP 1170, "Design and Operation of Solution-Mined Salt Caverns used for Natural Gas Storage"4 and API RP 1171, "Functional Integrity of Natural Gas Storage in Depleted Hydrocarbon Reservoirs and Aquifer Reservoirs".5 The IFR requires storage operators to comply expeditiously with both the mandatory and non-mandatory provisions of the recommended practices, with different sections required for new versus existing sites. Operators may decline to comply with non-mandatory components using technical justification to be reviewed by auditors. The IFR also provides for additional reporting requirements for operators beyond those noted in the RPs.

The IFR took effect Jan. 18, 2017 (Fig. 2). Operators have one year to demonstrate compliance, although some operators and industry groups are pushing back against this deadline. PHMSA accepted comments on the IFR until Feb. 17, 2017, but is not required by law to respond or make adjustments to the IFR. PHMSA has noted that it may revise or expand its gas storage regulations in the future. The IFR was issued following PHMSA's finding that "good cause" existed to respond quickly to safety risks to the public and to the environment.

PHMSA used the API RPs as an initial basis for its regulation of underground storage sites. API RP 1170 was published in 2015 to provide recommendations for salt caverns used for natural gas storage and covers geomechanical assessments, cavern well design and drilling, and solution mining techniques and operations, including monitoring and maintenance practices. API RP 1171, also published in 2015, applies to natural gas storage in depleted oil and gas and aquifer reservoirs (porous-rock storage), and focuses on storage well, reservoir, and fluid management for functional integrity in design, construction, operation, monitoring, maintenance, and documentation.

RP 1171 also details some of the major risk areas for porosity storage that have already informed risk-mitigation programs at some public utilities. Three main groups of risk areas and several subcategories are identified regarding porosity storage in API RP 1171:

• Surface.

Third-party damage.

Surface encroachment.

Intentional, unintentional damage.

Outside force; natural causes such as weather, ground movement.

• Reservoir.

Third-party damage.

Drilling, completion, and workover activities.

Production, injection, or disposal operations.

Geologic uncertainty.

Extent of reservoir boundary.

Expansion, contraction, and migration of storage gas.

Caprock failure.

Contamination of storage reservoir by foreign fluids; wellbore damage or corrosion.

• Wells.

Well integrity; corrosion, material defects, erosion, equipment failure, annular flow.

Design.

Operations, maintenance.

Intervention.

Third-party damage.

Outside force; natural causes such as weather, ground movement.

The API RPs generally are more detailed for well integrity than for reservoir integrity. This difference is echoed in a document published last year as a companion to the RPs by several industry groups including the American Gas Association.6 This document states: "Developed under a joint effort of regulators and industry, API 1170 and API 1171 are based on the premise that well life cycle integrity management requires good design, construction and operating practices. For the operations life cycle stage, site-specific risk assessments and integrity program and plan inspection, monitoring, testing and well intervention and remediation tasks are to be based on the operator's risk assessments, knowledge, experience and skill." The white paper further notes that "The risk-based approach to well integrity management advocated in API 1171 includes five steps: 1. Data Collection, Documentation and Review, 2. Hazard and Threat Identification, 3. Risk Assessment, 4. Risk Treatment-Developing Preventive and Mitigative Measures, and 5. Periodic Review and Reassessment… The operator's risk assessment must take a holistic approach to storage well and field integrity to effectively manage risk. It should be noted that while this (white) paper is focused on addressing the integrity of storage wells, some of the threats and preventive and mitigative measures pertain to both the storage wells and the storage reservoir. An example would be third party damage, such as vehicular impact to a wellhead (well risk) or a third party oil and gas producer drilling through the storage reservoir to a deeper formation (reservoir risk)."

In addition to the material contained by reference in the API RPs, PHMSA has mandated specific reporting requirements by storage operators that will contribute to a systematic national database for wells and reservoirs-caverns. The four new reports are:

• Annual reports that document operator name, address, and contact information; site location; number of injection, withdrawal, and observation wells; and operational information including gas storage volumes, pressures, well depths, injection and withdrawal rates, and maintenance schedules.

• Incident reports filed to document unintentional gas releases, death or serious personal injury, and substantial property damage.

• Safety-related condition reports that note pertinent issues such as corrosion of casing or tubing, mechanical defects in wells, earthquakes, or other aspects that may compromise the structural integrity or reliability of the facility.

• National Registry information that associates a storage operator with an assigned Operator Identification Number (OPID).

Recordkeeping requirements for operators include assessment, monitoring, planning, and actions taken to maintain safety.

DOE ITF

The US Department of Energy (DOE) and PHMSA created a joint interagency task force to examine the Aliso Canyon event in particular and the safety of underground natural gas storage sites in general. The task force's report provides a detailed description of the event as of mid-2016 and provides 44 specific recommendations to promote safety of underground storage sites.7 These recommendations centered on:

• Well integrity, with 13 recommendations including inspection, testing, risk management, monitoring, research, and data gathering.

• Reliability, with 11 recommendations including new analytical and planning tools for contingencies, variability in gas deliverability, and market conditions.

• Health and environment, with 20 recommendations including setting up advisory groups, unified commands for emergency response, monitoring networks, data access and timeliness, baseline data, and coordination between the operator and relevant regulatory bodies.

The report recommended in particular that operators develop and implement comprehensive risk management plans that are reviewed regularly by the appropriate regulator. Phasing out single-point-of-failure well designs, such as by installing downhole (subsurface) safety valves, and converting existing wells to tubing-and-packer configurations, was also recommended. The latter two changes are receiving some pushback from industry as they could likely add cost and reduce deliverability of gas in storage. The report notes that PHMSA will consider the task force recommendations in developing future regulation and safety standards as required by the PIPES Act.

California, independent studies

The Aliso Canyon event prompted extensive modifications to California's regulations for underground natural gas storage sites. External expertise from DOE's national laboratories supported efforts to stop the blowout. Clearer lines of authority were drawn between the many state agencies that regulate storage, including the Department of Conservation's Division of Oil, Gas and Geothermal Resources (DOGGR) and the Public Utilities Commission, to promote better coordination in the event of future leaks.

California implemented two major regulatory changes in 2016. The first was a set of emergency regulations, in force through at least 2021, intended to safely restart Aliso Canyon. These emergency regulations also led to a comprehensive safety review of the site, requiring that each of the 114 active wells at Aliso Canyon either pass a thorough battery of tests to resume gas injection or be taken out of operation and isolated from the underground gas reservoir.8 The review also required the establishment of a facility-wide emergency response plan and a safety and spill prevention plan.

The second set of regulations applied lessons learned from the Aliso Canyon event to all of California's storage sites.9 California has 14 underground natural gas storage projects in 12 fields with a capacity of 385.4 bcf. About 350 active wells are associated with those fields. The four regulatory goals include:

• Clarifying data standards. This sharpens the focus on both area of review, ensuring that injection remains confined to the intended zone, and geologic hazards that may further constrain a site.

• Creating well standards. This goal addresses the need to revise standards for casing, cementing, and reworking wells to tubing-and-packer designs, ensuring no single point of failure will compromise the well.

• Developing testing, monitoring, and risk mitigation plans. This goal seeks to clarify the methods, timing, and protocols for leak detection, mechanical integrity testing, and corrosion and valve testing. It also specifies improvements in risk management plans, such as what should be included and how often plans should be reviewed by the operator and reevaluated by the regulator to promote focus on a dynamic risk management plan that addresses potential hazards.

• Improving emergency response plans. The revised regulations emphasize strengthening this area to improve public health and safety, including specifying contingency plans, notification plans, and equipment and deployment plans. Also important is clarifying how the operator engages with incident command and regulatory bodies.

Independent studies have highlighted the need to include issues beyond well integrity to ensure the reliability of storage facilities. Gas or liquids can escape confinement via multiple mechanisms including accessing faults and fracture sets,10-12 confining zone caprock top-seal sequence failure, and structural spill points. Failures of reservoir integrity and gas leaks are well documented for all main types of gas storage site: including depleted oil and gas fields, salt domes, and mined caverns (Fig. 3).13 14 Standard practices for risk management include multiple-barrier models such as bowties15 and workflows that include well integrity, reservoir integrity, and operational-organizational elements.

Well integrity is obviously central to the safe and reliable operation of underground natural gas sites. But other technical and organizational elements have been noted in the regulations as critically important. These reliability elements include:

• Data management and action plans for both risk management and emergency response.

• Exposure, including proximity to infrastructure and previous blowout events at the site.

• Reservoir and cavern integrity, including adequate top and side seals for pressure integrity.

• Area-of-review monitoring, including surface methane, observation wells, and induced seismicity.

• Operations, including management of change and training of operational personnel.

References

1. US Department of Transportation, Pipeline and Hazardous Materials Safety Administration, "Pipeline Safety: Safety of Underground Natural Gas Storage Facilities," Interim Final Rule, Docket No. PHMSA-2016-0016, Federal Register, Vol. 81, No. 243, Dec. 19, 2016, p. 91860-91873.

2. StatesFirst, "Underground Gas Storage Regulatory Considerations," Interstate Oil and Gas Compact Commission and Ground Water Protection Council, 2017.

3. "Protecting Our Infrastructure of Pipelines and Enhancing Safety (PIPES) Act of 2016," Public Law 114-183, 114th US Congress, June 22, 2016.

4. American Petroleum Institute, "Design and Operation of Solution-mined Salt Caverns Used for Natural Gas Storage," API Recommended Practice 1170, July 2015.

5. American Petroleum Institute, "Functional Integrity of Natural Gas Storage in Depleted and Aquifer Reservoirs," API Recommended Practice 1171, September 2015.

6. Joint Industry Task Force (American Petroleum Institute, American Gas Association, and Interstate Natural Gas Association of America), "Underground Natural Gas Storage: Integrity and Safe Operations," July 2016.

7. U.S. Department of Energy, "Ensuring Safe and Reliable Underground Natural Gas Storage: Final Report of the Interagency Task Force on Natural Gas Storage Safety," October 2016.

8. California Division of Oil, Gas, and Geothermal Resources (DOGGR), "Requirements of Comprehensive Safety Review of the Aliso Canyon Natural Gas Storage Facility," Jan. 17, 2017.

9. DOGGR, "Chapter 4. Development, Regulation, and Conservation of Oil and Gas Resources," Aug. 1, 2016.

10. Katz, D.L. and Tek, M.R., "Overview on underground storage of natural gas," Journal of Petroleum Technology, Vol. 33, No. 6, June 1981, pp. 943-951.

11. Chen, M., Buscheck, T.A., Wagoner, J.L., Sun, Y., White, J.A., Chiaramonte, L., and Aines, R.D., "Analysis of fault leakage from Leroy underground natural gas storage facility, Wyoming, USA," Hydrogeology Journal, Vol. 21, No. 7, 2013, pp. 1429-1445.

12. Bruno, M.S., Lao, K., Diessl, J., Childers, B., Xiang, J., White, N., and Van der Veer, E., "Development of improved caprock integrity analysis and risk assessment techniques," Energy Procedia, Vol. 63, 2014, pp. 4708-4744.

13. Evans, D.J., "A review of underground fuel storage events and putting risk into perspective with other areas of the energy supply chain," Underground gas storage: Worldwide experiences and future development in the UK and Europe, editors Evans, D.J. and Chadwick, R.A., Geological Society, London, 2009, pp. 173-216.

14. Kron, N.D. and Malone, D.H., "Three-dimensional geologic model of the Pecatonica gas storage field, Winnebago County, Illinois," World Journal of Environmental Engineering, Vol., 3, No. 4, 2015, pp. 121-125.

15. International Association of Oil and Gas Producers, "Asset integrity: the key to managing major incident risks," Report Number 415, December 2008.

The authors

Richard A. Schultz ([email protected]) is senior research scientist in petroleum and geosystems engineering at The University of Texas at Austin and principal and owner of Orion Geomechanics, Houston. He holds a PhD in geomechanics from Purdue University, an MS in geology from Arizona State University, and a BA in geology from Rutgers University. He is a Fellow of the Geological Society of America, a member of the Interstate Oil and Gas Compact Commission, and a licensed professional geologist in the State of Texas.

Donnie Vereide ([email protected]) is vice president, business development with Geostock Sandia LLC, Houston. He holds an MBA from the University of Phoenix and a BS in petroleum engineering from Texas A&M University.