PHMSA needs to develop 2019 Final Rule performance measures

Adapted from US Government Accountability Office Report to Congressional Committees GAO-21-493 – “Pipeline Safety: Performance Measures Needed to Assess Recent Changes to Hazardous Liquid Pipeline Safety Regulations.”

The US Pipeline and Hazardous Materials Safety Administration (PHMSA) should develop and use performance measures to assess whether changes made as part of its 2019 Final Rule amending hazardous liquid pipeline safety regulations achieve desired outcomes and improve safety, according to the Government Accountability Office (GAO). These measures should include targets for the expected levels of performance to be achieved and specific timeframes in which to achieve these results. The Department of Transportation (of which PHMSA is a part) agreed with the recommendations made in GAO’s report, “Pipeline Safety: Performance Measures Needed to Assess Recent Changes to Hazardous Liquid Pipeline Safety Regulations.”

Selected pipeline operators and officials from PHMSA and selected states’ pipeline safety offices said the changes made under the rule would enhance pipeline safety and present no significant problems. They said the most beneficial changes expanded the scope of inspections; for example, expanding the use of specialized tools to inspect pipelines beyond high-consequence areas. While operators noted the rule’s potential to improve safety, all 11 operators GAO interviewed identified specific amendments that could increase costs. For example, several operators said they would need to modify or replace pipeline to allow for certain inspection tools required by the changes.

PHMSA held meetings with and provided guidance to operators and inspectors on the changes but has not developed measures to assess if the changes improve safety. Leading performance management practices call for agencies to track progress toward goals using measures that include targets for expected levels of performance and timeframes.

While PHMSA has desired outcomes for the 2019 Rule, including safety improvements, PHMSA officials said they have not established performance measures for those outcomes because some of the changes have long-term compliance deadlines, and so data are not yet available to assess effectiveness. However, other changes have shorter-term deadlines for compliance and PHMSA could use data it already collects from operators for its assessment. Without performance measures, PHMSA cannot determine whether the changes made by the 2019 Rule are achieving their intended outcomes and contributing to PHMSA’s safety goals.

Pipeline accident data

PHMSA data show that while the number of pipeline accidents has declined in recent years, accidents can still have significant consequences. PHMSA requires operators to report information on pipeline accidents resulting in a release of hazardous liquids. Hazardous liquid pipeline accidents increased from 344 accidents in 2011 to 460 accidents in 2015, which had the most accidents over the 10-year period reviewed (Fig. 1). Operators reported 330 hazardous liquid pipeline accidents in 2020, a reduction of about 28% from 2015.

Accidents resulting in fatalities, injuries, or an impact on the environment have also declined. Specifically, accidents that PHMSA identifies as those impacting people or the environment have declined about 43% since 2015 (Fig. 1). PHMSA defines an accident as impacting people or the environment if it meets one of the following two criteria:

- Regardless of the accident’s location, any of the following occur: a fatality, injury requiring in-patient hospitalization, ignition, explosion, evacuation, wildlife impact, contamination of specific water sources, or damage to public or private, non-operator property.

- Where the accident’s location is not totally contained on operator-controlled property, any of the following occur: an unintentional release of equal to or greater than 5 gal that is in a high-consequence area (HCA), an unintentional release of equal to or greater than 5 bbl that is outside an HCA, surface water contamination, or soil contamination.

According to PHMSA, while such accidents are relatively rare, they can have significant consequences. For example, according to PHMSA data, hazardous liquid pipeline accidents over the last 10 years have resulted in 8 fatalities and 14 injuries, and some accidents resulted in the release of hundreds of thousands of gallons of crude oil in HCAs.

PHMSA’s data showed most accidents in the last 10 years were contained on operator properties, such as pump stations and tank farms, and resulted in less than 5 bbl of product released per accident. For example, across the 10 years GAO examined (2011-20), 72% of all accidents were contained on the operator’s property and 61% of all accidents resulted in less than 5 gal of product released per accident. Furthermore, about 79% of all accidents that occurred 2011-20 were the result of a pipeline leak that generally causes less damage than a pipeline rupture. Only about 2% of all accidents that occurred between 2011 and 2020 were the result of a rupture.

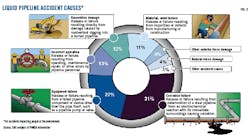

Pipeline accidents are caused by a variety of factors, including manufacturing issues, like pipeline defects, and age-related integrity issues, like corrosion. From 2011-20, PHMSA data show that the primary cause of about 50% of accidents impacting people or the environment was corrosion and equipment failure (Fig. 2).

Corrosion can occur on the exterior or interior of a steel pipeline, and operators use a range of technologies to protect pipelines, including applying coatings and cathodic protection to prevent corrosion from occurring if a pipeline’s coating is damaged. Pipeline equipment can also fail, such as a valve malfunctioning or pump cracking. Such failures may result in an accident.

Regulation changes

From 2010 through 2019, PHMSA worked on amending its hazardous liquid pipeline safety regulations. In 2010, PHMSA issued an Advanced Notice of Proposed Rulemaking to amend these regulations based on lessons learned from the spill of more than 840,000 gal of crude oil from Enbridge Energy Partners LP’s 30-in. OD Line 6B near Marshall, Mich., earlier that year. In 2012, PHMSA became subject to congressional mandates to conduct studies on topics such as existing regulations for gathering lines. NTSB issued its investigation report on the accident that included recommendations for PHMSA to revise and update its hazardous liquid pipeline safety regulations that same year (OGJ Online, July 11, 2012).

Also in 2012, GAO recommended that PHMSA collect data on unregulated gathering pipelines. In response, PHMSA published a notice of proposed rulemaking in 2015 to amend its hazardous liquid pipeline safety regulations and finalized these proposed amendments in the 2019 Rule. The 2019 Rule generally expanded safety requirements for pipelines in or affecting HCAs, extended certain requirements to pipelines located outside HCAs, and modified integrity management program requirements. As described in the accompanying table, each of these amendments to PHMSA’s hazardous liquid pipeline safety regulations have different timeframes for operator compliance.

Enhanced safety

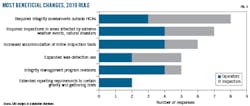

Selected stakeholders interviewed by GAO—including pipeline operators, officials from PHMSA, and selected state pipeline safety offices––generally told the agency that the changes made by the 2019 Rule would enhance the safety of hazardous liquid pipelines. GAO provided them a list of the key changes and asked the stakeholders to identify which among the list would likely provide the greatest benefit to safety. Fig. 3 summarizes stakeholder views.

While some operators and state agencies we interviewed said all of the major rule changes would benefit pipeline safety, stakeholders most frequently cited two changes as offering the greatest safety benefit.

- Integrity assessments of pipelines located outside HCAs. This change generally required operators to assess onshore pipelines located in areas outside of HCAs at least once every 10 years from the year of the prior assessment. Pipelines in non-HCAs account for about 130,000 miles or 58% of all regulated hazardous liquid pipelines, according to GAO analysis of PHMSA data. This change also requires operators to perform these integrity assessments of pipelines by using inline inspection (ILI) tools to identify threats to pipeline segments, including any anomalies. Three operators and officials from five federal and state pipeline safety offices stated that conducting assessments of pipelines in non-HCAs would provide pipeline integrity information on a greater amount of pipeline and on pipelines that had not been previously assessed.

- Inspections of pipelines after extreme weather events or natural disasters. This change requires operators to begin inspection of pipelines within 72 hr of extreme weather events, such as tropical storms, landslides, earthquakes, and other natural disasters that are likely to damage pipeline infrastructure. The change also requires operators to determine what damage may have occurred and to remediate any damage discovered. According to one operator interviewed, this change built on existing recommended industry practices and a prior PHMSA advisory bulletin that had primarily addressed pipeline inspection after flooding events. Additionally, two operators as well as one federal and two state pipeline safety inspectors said that the change would broadly benefit pipeline safety because it elevated a voluntary practice to a regulatory requirement, which standardized it across the industry. Several operators interviewed said they were already conducting such inspections as a matter of company policy.

Implementation difficulties

Stakeholders GAO interviewed generally said changes made by the 2019 Rule would not pose significant operational problems. For example, some noted that:

- Some of the more costly amendments, such as the accommodation of ILI tools, are mitigated by long phase-in periods.

- The 2019 Rule codified and expanded in regulation certain safety practices that already existed as industry best practices or practices recommended in PHMSA advisory bulletins.

All 11 of the selected operators said they were already performing at least one of the safety practices required by the amendments made by the 2019 Rule. For example, eight operators said that they were already performing integrity assessments of pipelines in non-HCAs before issuance of the 2019 Rule. Texas already requires operators to perform integrity assessments of pipelines in non-HCAs. Seven operators said that they were already conducting inspections of their pipelines after extreme weather events. Another noted that since the rulemaking process had taken several years, it anticipated some of the changes and had begun taking steps to implement them before issuance of PHMSA’s 2019 Rule.

In addition to operators, officials from the five PHMSA regional offices and six selected state pipeline safety offices interviewed generally said they did not anticipate any oversight difficulties resulting from the changes made by the 2019 Rule. PHMSA officials said that to implement the changes, the agency added an additional 59 audit questions to its more than 5,000-question Inspection Assistant tool, a comprehensive set of audit questions that federal inspectors use for the various types of pipeline inspections. PHMSA and state agency officials also stated that although the amendments will create some additional work for them, they will not affect inspection costs.

PHMSA regional offices and state agency officials noted, however, that some of the amendments would require more effort to monitor operators’ compliance than others. For example, officials stated that prescriptive requirements––such as whether an operator had filed a report by a deadline or had installed leak detection systems on their pipelines—would be the easiest to monitor. Conversely, inspectors cited requirements that called for them to make performance-based evaluations—such as evaluating steps operators took to identify interactive threats—as requiring additional analysis by the inspector.

Officials also noted that much of the additional work resulting from the changes would depend on the circumstances of individual operators. For example, PHMSA officials said that some smaller operators, lacking the resources of larger entities, may need more assistance bringing their safety programs into compliance. Similarly, state pipeline safety officials noted that the additional time inspectors would need to spend with a particular operator would depend on the experience, knowledge, and resources of that operator.

Potential costs

PHMSA’s final regulatory impact analysis estimated the total annualized costs for all operators to comply with the amended regulations at around $21 million. GAO did not assess the accuracy or reliability of PHMSA’s cost estimate. While more than half of the selected operators said they had not attempted to quantify the potential costs, all identified specific amendments that could result in cost increases. Potential cost areas would include:

- Training and staffing. While nearly all selected operators said that they would provide additional training to their staff to comply with the changes, several of the smaller operators said they would likely need to hire contractors to do so. For instance, one small operator, with fewer than 60 miles of hazardous liquid pipeline, said it would need to hire a contractor to conduct ILI inspections and data analysis to support integrity assessments of its pipelines in non-HCAs. Medium and large operators, however, generally said they did not anticipate having to increase their workforce to comply with the changes made by the 2019 Rule.

- Pipeline modification. Four of the selected operators said they would need to modify some of their pipelines to meet the amended requirement that pipelines in both HCAs and non-HCAs accommodate ILI tools within 20 years. One large operator said that the greatest cost effect from the changes would involve making all pipelines ILI compatible, particularly older legacy pipelines built before the existence of ILI tools. According to this operator, about 10% of its more than 10,000 miles of hazardous liquid pipelines are not ILI compatible. Another large operator said it has more than 200 pipeline segments in its 50,000 miles of pipeline unable to accommodate ILI tools.

- Equipment acquisition. Six of the selected operators interviewed said they would likely need to buy additional instruments and software to comply with several of the amendments made by the 2019 Rule. Five said they would need to acquire additional software, including software to help analyze the spatial relationships of anomalies and pipeline conditions identified in ILI assessments, to integrate the new data elements into their information analysis for pipeline integrity. Two operators said they had already acquired, or would also need to acquire, additional hardware to expand their use of leak detection. For example, one small operator said that, given the very rural location of its pipelines, it would need to acquire additional transmitters and meters for its leak detection systems.

PHMSA outreach

PHMSA has taken several actions to inform stakeholders of changes made by the 2019 Rule. In October 2019, PHMSA established an implementation team, including officials from PHMSA’s regional offices and state pipeline safety offices, to oversee implementation of the amendments. According to PHMSA, the purpose of the implementation team is to facilitate compliance with the amended pipeline safety regulations by hosting meetings with stakeholders, providing written guidance, and updating inspection and training materials.

The majority of selected pipeline operators and PHMSA regional office and selected state agency officials told GAO that PHMSA’s efforts to communicate changes made by the 2019 Rule to stakeholders were sufficient. For example, officials from one PHMSA region said they benefited from having staff members assigned to PHMSA’s implementation team because they were subsequently able to leverage these staff as a resource when reviewing the changes.

Performance measures

While PHMSA has identified several desired outcomes for its 2019 Rule supporting agency goals for the safety of hazardous liquid pipelines, it has not established performance measures with targets or timeframes to monitor progress in achieving these outcomes. According to PHMSA officials, this is because many of these changes have long-term deadlines for compliance and performance data will not be available for several years.

But some pipeline operators told GAO that they already had begun implementing these long-term requirements. For example, although operators have until July 2, 2040, to ensure their pipelines can accommodate ILI tools, one said it planned to prioritize pipeline modifications to segments that pose a higher safety risk, despite having 20 years to meet this requirement.

While these changes have long-term deadlines, GAO has previously reported that agencies can use intermediate or multi-year goals or measures to define intended results and show an indication of the incremental progress or contribution toward relatively long-term goals. In addition, there are amendments that have relatively short-term deadlines for compliance that PHMSA will have data available for that would enable it to develop measures. The amendment requiring operators to conduct pipeline inspections after extreme weather events and natural disasters became effective July 2020, and the amendment requiring operators to report accidents on certain gravity and gathering lines became effective March 2021.

PHMSA has recognized the importance in measuring performance of its rules but has not specified how it will do so for the changes made by the 2019 Rule. To guide the implementation of final rules, PHMSA prepared in February 2021 a “Fundamental Guide for Pipeline Safety Final Rule Implementation.” The guide provides examples of potential measures that could be used for assessing performance of rules, such as examining safety factors that relate to injuries, deaths, and environmental impact or assessing operational factors that relate to the number of inspections performed per year. PHMSA officials told GAO they intend to complete a more detailed standard operating procedure for the 2019 Rule’s implementation by December 2021, but it is not clear if it will include guidance related to developing performance measures with targets and timeframes.

PHMSA has previously developed measures to assess the performance of its safety programs, and it is currently collecting data that could be helpful in assessing the safety effects of the changes made by the 2019 Rule. For example, in response to a recommendation in GAO’s 2019 report, PHMSA recently established performance goals and measures to demonstrate improvements to safety outcomes for its natural gas storage program.

The agency already collects data from operators’ annual reports, accident reports, and safety-related condition reports that could be useful in assessing the safety effects of the changes. Agency officials said they could use these data to monitor changes in the number of safety-related conditions operators discover and the number of repairs operators make in complying with the amended safety regulations, such as the required integrity assessments for pipelines outside HCAs or inspections after extreme weather events.

PHMSA could also assess the number or percentage of non-HCA pipeline segments operators report as having been inspected with an ILI tool to assess progress in complying with this change. Establishing performance measures with targets and timeframes to assess the changes made by the 2019 Rule would enable PHMSA to assess its progress towards achieving the goals, identify gaps between actual and expected performance, and make timely adjustments to improve performance, as needed.

Although hazardous liquid pipeline accidents are relatively infrequent, leaks and ruptures do occur and can cause fatalities, injuries, and environmental damage. PHMSA’s 2019 Rule amending its hazardous liquid pipeline safety regulations has the potential to improve the safety of hazardous liquid pipelines, which have experienced a reduction in accidents impacting people and the environment in recent years.

Because PHMSA has not developed performance measures for the amendments, however, it does not have a means to gauge whether these changes are helping it achieve the desired safety outcomes of its 2019 Rule or its broader safety goals for hazardous liquid pipelines. Developing measures that identify the expected level of performance to be achieved from the changes within specific timeframes would enable PHMSA to assess the extent to which the implementation of the 2019 Rule is achieving desired outcomes, including improving safety. Further, such performance measures would give PHMSA information it can use to identify and implement any adjustments needed to better meet safety goals.