Automated gas-lift optimization reduces manual interventions by 85%

Bill Roberts

Rockwell Automation

Gas-lift (GL) operational inefficiencies are responsible for up to 5% of production shortfall in a typical oil well. A key difficulty is that surveillance, intervention, and optimization activities are performed manually. Resulting inefficiencies are compounded by the gas-lift rate’s sensitivity to other fluctuating variables, including compressor pressure, interference from nearby wells, hydrates, ambient temperature, and gas composition.

These factors cause gas lift rates to shift multiple times per day or even multiple times within an hour. When multiplied across dozens or hundreds of wells, over- or under-injection of lift gas will have a massive negative impact on oil production. Operators can attempt to correct these issues by visiting sites daily and adjusting gas lift rates to recommended set points, but even that’s typically not enough to keep up with these constant shifts.

Automating gas-lift optimization has reduced manual interventions by up to 85% in field trials. This automation can be achieved by pairing technologies such as a flow computer, cone meter, multivariable sensor, and electric-operated control valve with the operator’s automation and digitalization platform. The flow computer can automatically adjust the control valve based on data from injection-gas and production gathering systems to maintain assigned flow and pressure setpoints.

These steps allow well issues to be addressed in minutes rather than days, reducing production losses. In turn, operators can reduce site visits—from daily to perhaps 8 days/month—and limit those visits to activities like critical interventions and testing. This frees up operators to focus on higher-value or more critical tasks, such as optimization and related enhancements to reservoir- and well-interference performance.

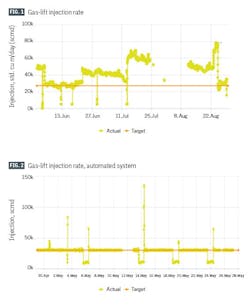

Fig. 1 shows a well that was experiencing high gas-lift fluctuation and Fig. 2 the reduced fluctuation it experienced after deploying an automated GL system.

ESP response prioritization

Bringing production data together in a centralized platform creates new opportunities to optimize the performance of electrical submersible pumps (ESP). One example of this is the use of an AI-powered response prioritization system.

Such a system can detect developing conditions that may escalate to imminent low-flow events. The system can then proactively alert teams of these conditions in real time, enabling them to act quickly to prevent further escalation and potentially avoid issues like production losses and pump damage.

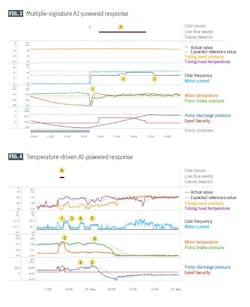

In one case (Fig. 3), an AI-powered response prioritization system flagged an insufficient lift event (A) for a pump based on three signatures. For one, the system identified that the motor temperature rose above its expected reference value by 6° F. after the pump started (Point 1). It also recognized that intake pressure was trending upward and identified motor current 10% lower than its expected reference value.

The event was communicated to surveillance engineers, who increased pump speed (Point 2) to establish the desired flow and recover from the event. Afterwards, the pump was safely returned to its original reference frequency (Point 3).

In another case (Fig. 4), the system flagged an insufficient lift event (A) after it identified a rapid increase of about 13º F. in motor temperature. Such overheating can indicate low-flow conditions and damage the pump.

The surveillance team took prompt action, increasing the pump speed (Point 1) to increase flow and reduce motor temperature (Point 2). If they hadn’t intervened, the event could have easily escalated and resulted in a trip and shutdown. Eventually, the team was able to decrease the pump speed to its original level (Point 3).

This event spurred the team to set a new strategy for increasing production at a lower intake-pressure target. Two initial attempts to increase the pump speed (Points 4 and 5) resulted in an increase in pump discharge pressure. In another attempt, the team opened the surface choke (Point 6), which increased flow toward the new intake pressure target of about 175 psi. The team used reference signals from the system to help navigate this transition without triggering any events.

Midstream throughput optimization

Pipeline and processing-plant operators either inject chemicals or use heaters to keep the materials they’re handling in the right phase and prevent the formation of hydrates. Because process-state information is incomplete, however, they tend to overcompensate, injecting more chemicals or producing more heat than is required.

Data-driven optimization tools can give midstream operators visibility into their processes so they can run at optimal conditions and maintain the correct phase envelope. One of the enabling technologies in these tools is an edge controller that can model the process with consistent thermodynamics and fluid characterization, providing a real-time indication of hydrate temperature based on current composition.

These insights allow optimization of chemical injections or heaters adjusted either by operators or by a closed-loop control solution, improving throughput, bottom line, and sustainability.

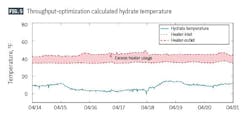

In one case (Fig. 5), a pipeline operator had been running its 500,000-btu heaters year-round to prevent hydrate formation, even though hydrate formation wasn’t a risk most of the year. To lower costs and reduce emissions, the operator deployed a closed-loop control solution, which would activate the heater when hydrate temperature approached to within 10° F. of the heater inlet temperature. After starting, the heater would run for a minimum of 1 week before being turned off when the hydrate temperature differential had been greater than 10° F. for at least 3 consecutive days.

This optimization dramatically reduced heater usage, from the continuous, year-round operation to just 2 weeks of runtime annually over the 2 years following implementation. This helped reduce the duty cycle of the heater 96% and led to savings of $20,000/year in natural gas costs. With a better understanding of the phase envelope, the operator also increased its propane shipments through the natural gas pipeline by about 20%.

Reimagining operations

A connected, data-driven approach creates new possibilities from the start of oil and gas operations to maximize performance, savings, and sustainability across the life of projects. A prime example of this is in the development of floating production, storage, and offloading (FPSO) vessels. Taking a “connected vessel” approach at the start of these massive operations can optimize performance while delivering savings from the shipyard to the end of their life cycle. This approach imbues connectivity into several aspects of an FPSO.

The vessel’s production modules, for example, would all have standardized systems so they will connect to the main vessel systems regardless of which original equipment manufacturer delivered them. This can help reduce the risk of schedule overruns during commissioning and startup. Standardized modules can also reduce the risk of containment loss by using consistent designs and improved maintenance practices and asset-management strategies. Additionally, the vessel’s connected production platform allows visibility and solutions for flow assurance, from the reservoir through the vessel’s production modules. Capabilities like reservoir analysis and management can also help optimize production across the vessel’s life.

Vessel workers are also connected. They can use digital technologies to access information as they need it as well as human expertise whether it’s on the vessel or onshore. A connected onshore operations center can also serve as a centralized location for coordinating operations across the life of the vessel. This can reduce both the number of on-board staff required and the number of trips specialists need to make to the vessel, cutting costs and risks.

Author

Bill Roberts has been involved in the oil and gas and process industries for more than 25 years. For the past 6 years he has been supporting the Rockwell Automation oil and gas sales team in North America. His current focus is helping customers automate and digitalize their business to improve their cycle time, address operational needs, and reduce costs. Bill graduated from Texas A&M University and earned his MBA from Houston Baptist University, Texas.

Acknowledgement

The author thanks Sensia Global for its assistance with the figures presented and additional data.