Polymeric relative permeability modifiers enhance oil recovery

Ksenia Arkhipova O’Connor

Louis S. Caiola III

Rebecca Casillas

Elsa Garcia

Ryan van Zanten

Alexander Patalakha

Shell USA

Houston

New Orleans

Conventional water shut-off often uses mechanical isolation or fluid gel-resin options. In restrictive simultaneous operations (SIMOPs) scenarios or adverse price environments, operators struggle to justify conventional intervention strategies such as a wireline deployed mechanical isolation. Relative permeability modifier (RPM) engineered fluid systems, however, offer an advantage by avoiding a rig, wireline, or coiled tubing unit for deployment.

Shell USA Inc. combined RPMs with acid stimulation in two candidate wells with high water cut and relatively low permeability at Auger field in the Gulf of Mexico (GOM). Application of an RPM treatment, especially with acid staging, is a relatively novel GOM implementation.

Overall results were positive and the increase in rates following RPM treatment exceeded those anticipated solely for acid stimulations. Water cut reduction, however, was only partially successful and short-lived. The total project broke even within a couple weeks based on incremental production above baseline after treatment.

RPM applications

RPMs are pumped from surface to adsorb onto water-wet pore surfaces, altering relative fluid permeability and reducing water movement while allowing hydrocarbon flow (Fig. 1). They treat the reservoir without mutual solvents or surfactants and can be more cost effective with lower operational risk than mechanical water shut off. Polymers are typically used in RPMs with variations in structure, crosslinking, and buffering chemistry.

RPMs can comprise part of a larger stimulation fluid package. When included as part of an acid package, RPM stages can provide strong diversion and maximize interval coverage efficiency for main-stage treatments to target more hydrocarbon-prolific zones. Hybridized treatments, however, may reduce RPM effectiveness due to polymer and acid chemical interactions. In these cases, separate RPM pills optimize reservoir treatment.

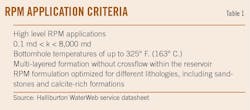

An operator can maximize the probability of success (PoS) of these treatments by selecting candidates that offer the correct mix of net well flow rate, producing interval geological architecture, and fluid system-staging in pumping operations. Table 1 shows the ideal well conditions for RPM applications. Field data suggest the lower limit should be 100 md given pumping-injectivity problems observed for the RPM-heavy crosslinked polymer.

The effective permeability of a candidate well is critical given the size of the crosslinked RPM polymer. RPM polymers should be tailored to the pore throat architecture. There are limited commercial RPM options to explore, but optimized RPM polymers are possible through stronger formation-optimized adsorption properties, additive nanotechnology, and emulsion resistant crosslinking or gelant properties. Additionally, temperature-dependent polymeric shearing and viscosity are important factors for effective interval coverage.

Auger

The Auger tension leg platform (TLP) in the western Gulf of Mexico produces from parts of nine Garden Banks offshore US continental shelf lease blocks. Auger has mainly gas condensate wells, but some wells exhibit black oil characteristics. First oil was achieved in 1994.

The TLP is installed in 2,864 ft of water and can process 90,000 bo/d, 250 MMscfd, and 40,000 bw/d with total liquid capacity limit of 105,000 b/d. The Auger asset consists of the Auger Direct Vertical Access (DVA) field (dry wells) and five active subsea tiebacks.

As a late-life field, Auger experiences high water production, with a few DVA wells having water cuts more than 60%. Water production causes intermittent production and lift issues, limits wet train capacity, and results in wellbore and flowline slugging. As a result, the asset is suffering from water capacity bottlenecks.

DVA wells that would most benefit from water shut off (WSO) have restrictive downhole internal diameters (ID) for mechanical shut off and deck-space constraints for wireline applications. Based on the ongoing DVA rig campaign, a stim vessel bull-heading operation was proposed to convey RPM WSO treatments. A stimulation pill was added to the treatment to take advantage of the strong diversion properties of the RPM and increase overall effectiveness of the WSO treatment. Two wells with the highest probability of success were selected for trial, with an anticipated treatment effectiveness of least 6 months.

Candidate selection

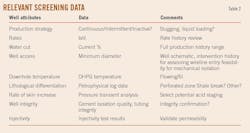

All DVA wells were considered for WSO applications as well as some subsea (wet tree) wells using screening criteria (Table 2). Conventional mechanical WSO options were also assessed in conjunction with chemical WSO. Wireline technical limitations and uncertainty of which zone was producing water limited mechanical WSO, leading to a novel chemical WSO treatment. The high OPEX exposure and relatively low fluid treatment PoS for subsea wells focused treatment on DVA wells during screening. A decision tree framed the screening philosophy for RPM WSO against conventional options (Fig. 2).

Well candidates need sufficient pore pressure-fracture pressure margins for pumping given rapid increases in treating pressures as RPM reaches the interval. The service operator also needs to confirm whether cycling injection is a viable contingency, otherwise severe injectability issues could create premature formation lock-up exposure with potential acid in the tubing string if RPMs are staged before acid. A coupled-treatment design with RPM staging in the lead should only be executed in scenarios where there is high confidence in injectivity with heavy cross-linked polymer and >100 md effective permeability.

Candidate selection was largely driven by value drivers of the asset. The Auger asset team hedged against a failure of a new fluid technology and treatment design in several ways. The impermanence of the chemical WSO RPM treatment was endorsed as the preferred path forward while acknowledging the limited upside from a value perspective. Combining the RPM treatment with an acid stimulation package, however, improves upside rate expectations despite the uncertainty of RPM treatment effectiveness in a coupled fluid package. Additionally, the selected stimulation vessel had capacity for two combination stimulation jobs. Therefore, the decision was made to pursue two treatment candidates that would offer the highest PoS among the well candidates.

The following criteria technically screened candidates at the asset:

- Well candidates must exhibit about 30-80% water cut.

- Well candidates should produce < 5,000 bw/d (ideally < 2,500 total b/d).

- The treatment must be relatively easy to deploy compared with conventional wireline conveyed WSO solutions.

- The treatment must allow for SIMOPs.

- Treatment equipment footprint must fit within deck constraints.

- There must be high permeability and high lithological differentiation in the producing interval (such as shale breaks).

- The well must be a candidate for acid stimulation.

Wells were selected with sufficient water cut (>30%) to mitigate potential impairment of oil producing zones with the RPM cross-linked polymer. To maximize PoS, targeted wells ideally have < 2,500 b/d total liquid rates. In general, higher rates will decrease the duration of effectiveness of the RPM treatment because treated zones will likely degrade sooner. A 10-20% water cut reduction for incremental lift efficiency served as a basis for all economics.

When pairing RPMs with an acid stimulation treatment, higher rates from the stimulation may erode the effectiveness of the RPM treatment from the lower pH exposure. This risk can be reduced if the well’s producing interval has clearly identifiable wet and dry zones in stratified lobes. Understanding producing interval layering and their respective fluid-type contribution increases PoS for a treatment design, especially for water-wet high permeability regions. In these circumstances, an RPM pill pumped before acid stimulation maximizes acid diversion while limiting polymer-adsorbate film degradation from acid exposure. In contrast to these ideal circumstances, selected Auger wells had relatively blocky sandstone intervals with high uncertainty regarding effective permeability of water-wet zones.

The Auger asset used a simplified screening table to assess well treatment viability (Table 2). Two wells (Well #1 and Well #2) were selected for the combination acid and RPM treatment given their relatively high PoS. The wells had the lowest production rates among the candidates and exhibited 30-80% water cuts. Additionally, Well #1 had already been economically screened for acid stimulation, and the RPM treatment increased the value case of the acid stimulation. Well #2 had equal value placed on acid stimulation for fines migration and water shut off based on its significant liquid loading history.

Intervention preparation

RPMs were selected for the Auger asset based on prior history and low probability of the treatment chemical causing harm. For the combination RPM-acid stimulation job, RPM effectiveness is difficult to isolate from overall treatment results. Reservoir compatibility tests ensured safe treatment by mixing crude and treatment fluids at varying ratios and heat-aging at bottomhole temperature (BHT) for 16 hours, mixing gently again and passing the fluid through a 100-mesh screen to look for precipitates or viscous emulsions.

When crude from both proposed wells were tested with RPM fluid, the screen retained a small amount of polymer sludge and emulsion. The presence of sludge failed the test, and a non-emulsifier was added to the treatment fluid. Both crudes passed compatibility. The addition of 0.1 vol.% of non-emulsifier did not affect the performance of the RPM treatment. The fluid was also mixed with live and spent acid blends, and no issues were observed once the non-emulsifier was added.

RPM execution

Well #1 experienced significant reduction in injectivity during about half the RPM treatment volume. An immediate surge in pumping pressure occurred as RPM reached the perforated interval (Fig. 4). Pump rate was reduced until the pressure dropped safely below the maximum allowable limit. Subsequent injection attempts increased pump rate but never exceeded 2 bbl/min. The complete treatment was eventually injected into the well in about 34 hr (53 hr total stimulation time).

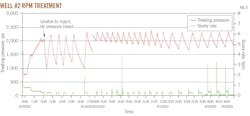

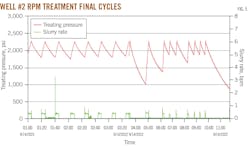

Well #2 exhibited similar behavior during RPM injection (Fig. 5). Shortly after RPM reached the perforated interval, pumping pressure experienced an immediate and sharp increase, reaching the maximum allowable pressure. Pumps were shut off to allow pressure to dissipate. Attempts to push the treatment into the reservoir with both short and long pumping cycles failed to reduce surface pumping pressure, and a sharp decline in injectivity was observed during the RPM stage. After about 28 hr of injection, only 60% of the planned RPM volume was placed into the well, equating to 25% of the total RPM volume pumped into the formation with the remainder in the wellbore and pipes. The reduction in injectivity was so severe that only 5% of the planned RPM was injected in the last 19 hr. Average pumping rate was 0.08 bbl/min, recalculated from necessary frequent stops to manage pressure. Total stimulation time was 37 hr. Figs. 3-5 show RPM cycles on both wells.

Well #1 received an estimated 10 ft radius treatment. Well #2 received only about 4.85 ft radius treatment, about 2.15 ft short of the minimum recommended by the RPM product supplier. The formation did not imbibe most of the treatment. Continuing attempts to squeeze into the formation increased the risk of a difficult flowback operation. The displacement fluid was also reduced in volume to avoid further poor displacement and pump failure. The slow injection rate on both wells led to cost overruns.

Flowback to host

Table 3 summarizes results for the two wells before stimulation, immediately after stimulation, 1 month after stimulation, and 1 year after stimulation. All rates were measured on a test separator and converted to standard conditions. Shakeouts estimated water cuts.

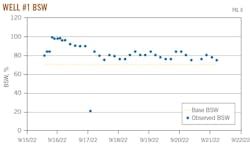

Before stimulation, Well #1 produced steadily at 300 bo/d and 69% water cut with a fully-open choke. At the start of unloading, the well was slowly brought up to almost 2,000 b/d total liquid at relatively small choke-opening and was left to produce for several days. For the first nearly 3,000 bbl, returns had the characteristic smell of ammonium chloride (used in a diverter) and chloride salts, with substantial foaming which likely impacted early readings of basic sediment and water (BSW). Subsequent samples had a less intense chlorine-ammonia smell, indicating that less injected fluids were recovered (Fig. 6).

There were no observed emulsions before rerouting the well to the normal process train. Three days after well rerouting, however, low suction pressure on the suction strainer and differential pressure transmitters on the pipeline pumps indicated blockage. A sample was taken from the test separator and contained heavy emulsion. An additional sample was collected from the Well #1 line to identify the emulsion source (Fig. 7). FTIR spectroscopy performed on the emulsion sample indicated absorbances associated with carbonyl (C=O) and hydroxyl (OH) functional groups which could be due to the presence of an unknown fatty acid component either in the treatment or from the formation.

Well #1 was shut in and the test separator cleaned and flushed. After 10 days of shut in, the well was restarted with no further issues or emulsions. Well #1 maintained production rates above pre-stimulation rates 1 year after the stimulation and maintained a relatively stable water cut.

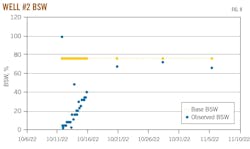

Before stimulation, Well #2 did not flow for 3 months because of liquid loading. Attempts to restart the well before treatment were not successful, and there were concerns about well flow after stimulation. Early cessation of pumping operations left the tubing filled with RPM, compounding difficulties for successful flowback.

After treatment, the well restarted with low initial flow after 5 days shut-in. The well was kept open to unload as much heavy fluid as possible. After 10% of the volume was removed, another shut-in during the second flowback of Well #1 (after the emulsion was observed) resulted in a shift in pressure indicating gas cap formation. A subsequent restart was successful, and initial shakeouts indicated 4% BSW.

BSW maintained low values for about 3 days before trending below baseline. When compared with Well #1, BSW remained below baseline before stimulation and settled at about 10% below baseline (Fig. 8). The well did not produce emulsion, and the stimulation was considered successful with a five-fold increase in productivity from both acid and RPM treatments, with peak rates constrained by other system limitations such as high temperature and trapped annulus pressure. Despite the well receiving less product than Well #1, it had better overall water shut-off.

The well was put on continuous production with a higher rate than pre-stimulation. After a year of production, the well exhibited week-long periods of low water cut after planned shutdowns. Water cut varied throughout the year, generally remaining higher than 75% BSW, with shakeout samples occasionally registering as low as 55% BSW. The lack of water cut reduction, specifically for Well #1, may be due to limited adsorption efficiency or duration of the RPM treatment, even though it effectively displaced acid through the damaged matrix.

The stimulations also produced higher pressure in the wells which allowed them to route to a high-pressure system, creating relief for the water-constrained low-pressure system. As a result, the wells could be maintained at the achieved high rates and rerouted to the low-pressure system later for rate optimization.

RPM observations

For these RPM treatments, long pump times led to expensive treatments and, in the case of Well #2, required ending the job early. To minimize this risk, permeability assumptions need to be validated during the screening stage and the fluid package needs to be optimized to lead injection with RPM staging.

A designated flowback test separator should be prepared for potential separation or emulsion issues as were observed with Well #1. Carbonyl and hydroxyl functional groups identified in the highly viscous returns from Well #1 appeared to be derived from the presence of a fatty acid of unknown origin. This is a potential risk when pumping RPMs. Some polymeric RPM structures include organic linkers which could be the source for these organic fatty acids but were not identified as part of this treatment’s polymeric design from the vendor. Tough organic emulsions were not an issue for Well #2, but injectivity decline forced a premature end to the pumping operation and multi-day delay to flowback. The residual quantity of RPM (roughly 40% of the planned volume) was unable to be reused, which required a sizeable disposal fee. It is recommended to identify either a potential back up buyer or additional candidate-well for RPM treatment as a contingency measure.

While the short-term rate results were exceptional, changes in long-term operational strategy and asset production forecasts were perhaps more impactful. A 3-year well-life extension was applied to Well #1 after increasing rate to a stabilized 1,000 bo/d oil (63% water cut) from 300 bo/d oil (69% water cut) after 1 month of production. Well #2, which had been shut in due to liquid loading with a water cut of 75%+, was returned to continuous production. Although the initial substantial water cut reduction to 4% was short-lived, the water cut remained below pre-stimulation levels for roughly 3 months. This duration was in line with the expected duration for the temporary RPM treatment design. In addition, the well continued to flow a full year after stimulation.

Considering that an earlier standalone acid stimulation on Well #1 did not have the same level of efficiency (only 50% improvement), the substantial increase in production rate was most likely due to more effective acid displacement into the reservoir by the RPM. This effect has been observed in case studies from 30 wells in the GOM. In these studies, however, RPM was injected first, followed by the acid. In this Auger case, the order was reversed, with acid stages leading the RPM treatment.

Bibliography

Chao, Y., Navarrete, R., and Mahmoud Asadi, M., "A Novel Relative Permeability Modifier Polymer," SPE International Conference and Exhibition on Formation Damage Control, Lafayette, La., Feb. 19-21, 2020.

Duverney, E.S., Robles, F., Lopez A.I., and Steffani, O., “Relative-Permeability Modifiers and Their Use in Acid Stimulation in HP/HT Low-Permeability Carbonate Formations: Offshore Mexico Cases,” SPE Latin American and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, Apr. 15–18, 2007.

Naima, S., Lant, K., Akshaya, S., and Billy, G., “Got Water? An RPM Solution”, International Petroleum Technology Conference, Riyadh, Saudi Arabia, Feb. 21-23, 2022.

Parkhonyuk, S., Levanyuk, O., Oparin, M., Sadykov, A., Mullen, K., Lungwitz, B., Enkababian, P., Mauth, K., Sosenko, )., and Karpukhin, A., “Implementation of Relative Permeability Modifiers in Krasnoleninskoe Oil Field: Case Histories”, Eighteenth SPE Improved Oil Recovery Symposium, Tulsa, Okla., Apr. 14–18, 2012.

Qin, L., Myers, M.B., Otto, C., Verrall, M., Zhong, Z., Arjomand, E., Saeedi, A., and Wood, C.D., “Further Insights into the Performance of Silylated Polyacrylamide-Based Relative Permeability Modifiers in Carbonate Reservoirs and Influencing Factors”, ACS Omega, Vol. 6, No. 21, 2021, pp. 13671-13683.

Authors

Ksenia Arkhipova O’Connor ([email protected]) is a senior production engineer for deep water GOM and well integrity subject matter expert at Shell USA, Houston. She holds MS (2006) in reservoir engineering from University in Stavanger and MS (2007) in production engineering from Gubkin Russian State University of Oil and Gas. She is a member of SPE, Well Integrity and Abandonment Society (WIA), and Offshore Operators Committee (OOC).

Louis S. Caiola III ([email protected]) is a production engineer at Shell USA, New Orleans. He holds a BS (2017) in earth systems engineering and an MS (2018) in chemical engineering from Cornell University. He is a member of SPE.

Rebecca Casillas ([email protected]) is a senior deepwater production engineer at Shell USA, Houston. She holds a BS (2006) in petroleum and natural gas engineering from Penn State University and PMP certification (2022) from the Project Management Institute. She is a member of the Society of Petroleum Engineers and Women’s Energy Network.

Elsa Garcia ([email protected]) is a staff well engineer (completions and well interventions) at Shell USA, Inc., Houston. She holds BS (2008) in mechanical engineering from The University of Texas-Pan American. She is a member of SPE.

Ryan van Zanten ([email protected]) is lead production engineer at Shell, Houston. He holds a BS (2000) in chemical engineering from Colorado State University and PhD (2007) in chemical engineering from University of California, Santa Barbara. He is a member of Society of Petroleum Engineers (SPE) and American Association of Drilling Engineers (AADE).

Alexander Patalakha ([email protected]) is a lead wells engineer at Shell USA, Inc. Houston. He holds an MS (2000) in petroleum engineering from the Gubkin State University of Oil & Gas in Moscow. He is an SPE member.