DG Fuels advances Louisiana SAF production complex

DG Fuels LLC (DGF), Washington, DC, is progressing with its plan to build a grassroots complex in St. James Parish, La., for commercial-scale production of sustainable aviation fuel (SAF).

First announced in 2023—and with anticipated production volumes now committed to global aviation partners under long-term offtake agreements—the proposed multibillion investment will involve construction of a very low carbon dioxide (CO2) lifecycle emissions complex equipped to produce synthetic, low-emissions SAF from a feedstock of locally sourced, waste-biomass feedstock using DGF’s proprietary system that modifies the long-proven Fischer-Tropsch (FT) technology process.

In addition to presenting an overview of the DGF St. James Parish SAF project, this article examines DGF’s selection of technologies, proposed production plan, and selection of service providers and partners for the project.

Project details

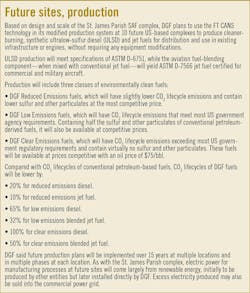

DGF’s proposed Louisiana investment project is the first of 11 similar US-based plants the operator plans to develop for domestic production of SAF to help meet rising demand from the aviation sector for low-to-no-carbon jet fuel supplies required by airlines to achieve various net-zero emissions targets in line with the ongoing global energy transition.

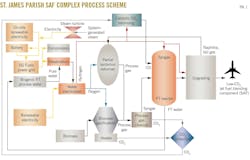

Estimated at an overall investment of $3.8-4.8 billion, the Louisiana project will be built on part of a 3,000-acre site along the west bank of the Mississippi River, near Moonshine, La., in St. James Parish (Fig. 1).

Based on current design but subject to potential expansion in scope, the St. James Parish complex would process locally sourced agricultural and biowaste feedstocks—including sugar cane, timber, and other plant waste—to produce 600,000 tonnes/year (tpy; about 13,000 b/d) of SAF that can be directly used in lieu of conventional jet fuel to reduce commercial-flight CO2 emissions by up to 100%.

Relying entirely on cellulosic waste products from the regional farming and logging industry, and to be partially powered by renewable energy sources such as wind and solar, the low-emission biofuel complex would not release any fossil fuel-related emissions into the atmosphere or discharges of any type into the Mississippi River, while at the same time providing the local agricultural community a direct customer for multiple forms of its biogenic waste.

Upon releasing an economic impact study (EIS) for the project completed by BEC Research LLC in January 2024, DGF committed to purchasing about $120 million/year of sugar cane waste—nearly a third of which will come from St. James Parish farmers—as plant feedstock. Alongside presenting farmers with a profitable alternative to burn harvesting, DGF’s local sourcing of feedstock will also result in air-quality improvement across the region, according to the EIS.

In addition to the SAF plant, the energy complex will include installations for feedstock pretreatment, feedstock and product storage and handling, and administrative offices (Fig. 2).

Once operable, the St. James Parish plant’s production of SAF would be blended up to 50% with fossil-based kerosine to create enough drop-in SAF to power more than 30,000 transatlantic commercial flights annually, helping reduce the aviation industry’s CO2 emissions by about 1.65 million tpy.

Aside from ongoing discussion with partners and state regulators in Maine for establishing what would be its second US SAF biofuels complex, DG Fuels has yet to reveal locations of its future projects (Fig. 3).

Technology, production

In late-March 2024, DGF let a contract to Johnson Matthey (JM) and bp PLC to license their jointly developed FT CANS technology for the planned St. James Parish SAF complex.

DGF will use the FT CANS technology to convert synthesis gas derived from the complex’s biomass feedstock into synthetic crude (syncrude), which is then further processed to produce synthetic kerosine that will subsequently be blended with conventional jet fuel to produce SAF.

Most SAF currently supplied to market is derived using hydrotreated esters and fatty acids (HEFA) conversion, primary feedstocks of which include waste fats, oils, and greases. While the HEFA synthetic paraffinic kerosine (SPK) method now serves as the main commercial pathway to produce SAF at scale, feedstocks for this pathway are becoming increasingly limited, requiring a growing need for commercial, large-scale sustainable feedstock mobilization.

While DGF’s baseline high-carbon conversion system for SAF production is based on the FT method, the operator’s patented system modifies the process in several ways that reduce the quantity of required feedstock, eliminate the need for carbon sequestration, and lower feedstock handling costs and complexity.

Fig. 4 shows DGF’s proposed production scheme for SAF at the St. James Parish complex.

To reduce feedstock quantities and related emissions, DGF’s modified system enhances the traditional FT process via the addition of water electrolyzers that— powered by renewable energy sources—produce clean oxygen and hydrogen for recirculation into the SAF production process.

Whereas conventional refineries and gas-to-liquid plants typically convert about 85% and 60% of carbon contained in their respective crude and natural gas feedstocks into products, cellulosic biofuels plants to date have managed to achieve a carbon utilization of only about 25% from their biomass feedstock into products.

Unlike its predecessors, DGF said its adapted system breaks the carbon-utilization barrier to achieve a utilization efficiency of up to 97%. This level of carbon-utilization efficiency combined with renewable hydrogen as a drop-in replacement fuel result in the operator’s modified system achieving more than 100% lower greenhouse gas emissions (GHG) on a full-lifecycle basis, DGF said.

DGF’s production system ability to achieve higher utilization of biomass feedstock than conventional biomass-to-liquids projects results from the operator’s reuse of waste CO2 to make additional fuel. Depending on feedstock carbon content, DGF said its modified system produces up to 3.6 bbl of biogenic blending component/tonne of biomass feedstock, while most competitors achieve about 1.1-1.3 bbl/tonne of feedstock.

DGF’s adapted system ultimately yields a product with a negative CO2 lifecycle of 104.2% less (-3.5 gCO2e/MJ) than petroleum-based jet fuel, which has an average CO2 lifecycle of 94 gCO2e/MJ, according to the operator.

Already certified by ASTM International as a renewables-based, lower-density, drop-in replacement fuel for existing aircraft engines and estimated to be price-competitive with petroleum-based jet fuels, DGF’s SAF production will be followed by future use of the modified system to produce synthetic diesel fuel (see sidebar).

Without revealing additional details, the company said it is also leading other research and development efforts to further advance biofuel technology, which include implementing multiple catalytic processes to increase yields of hydrocarbons from sustainable feedstocks for use as liquid substitutes in conventional fuels.

Project partners

In addition to licensing of the FT CANS technology from JM and bp, DGF has enlisted a series of other service providers and project partners for the St. James Parish SAF complex.

In December 2023, DGF let a contract to Maire SPA subsidiary NextChem SPA’s waste-to-chemical segment, MyRechemical SRL, to deliver process design and serve as technology licensor of the proposed complex’s gasification and gas treatment units that, together, will be able to process 1 million tonnes/year (tpy) of locally sourced agricultural waste as a first step in the site’s SAF manufacturing process.

MyRechemical’s gasification and purification technologies will enable the units to specifically process bagasse—the matted, cellulose-fiber residue byproduct of post-processed sugarcane stalks—as well as other sugarcane waste and pulp material into suitable feedstock for DG Fuels’ production of zero-carbon SAF.

In early November 2023, the operator contracted Emerson Electric Co. to deliver comprehensive automation and project engineering services for the project, including a suite of advanced sensing, control, systems, equipment monitoring, and production optimization technologies. That same month, DGF—which in October 2022 signed a multiyear SAF offtake agreement with Air France KLM for up to 600,000 tpy for delivery between 2027 and 2036—entered additional agreements with the airline, under which Air France-KLM acquired a new option to purchase up to another 75,000 tpy.

Under the revised offtake option, 30,000 tpy of SAF would come from the proposed Louisiana complex, with the remaining 45,000 tpy to be delivered from the future Maine SAF complex starting as early as 2029.

As part of those November agreements, Air France-KLM also confirmed its investment of $4.7 million in DG Fuels to support completion of remaining development work required ahead of the operator reaching final investment decision (FID) on the Louisiana SAF complex.

Upon announcement of the Air France-KLM investment, DG Fuels said it plans to continue working with the airline to deploy its proprietary SAF technology at additional locations in the US, as well as yet-to-be-identified locations in Europe and the Asia Pacific.

DGF previously contracted Black & Veatch to perform feasibility, early engineering, and environmental permitting work on the project.

Should plant construction move forward, Black & Veatch—which also performed the project’s front-end loading (FEL-3) engineering report—would serve as engineering, procurement, and construction (EPC) contractor, DG Fuels confirmed.

Good neighboring

Of all the partnerships DGF has formed in furthering development of the proposed Louisiana complex, perhaps its most important is the community of St. James Parish itself, as ultimate approval for the clean energy complex advancing hinges on local authorities.

After release in early 2024 of the project’s EIS and following consultation with local community leaders and residents, DGF announced in late-February 2024 that the St. James Parish Council had awarded its support to a legally binding $26-million community benefits agreement (CBA) DGF has committed to fulfilling upon project approval. The support followed DGF’s granting of amendments requested by councilmembers and future site neighbors to the original plan.

As part of the CBA, DGF has agreed upon taking FID for the project to contribute $9.3 million in up-front community investments and another $16.75 million in community benefits over a multiyear period to ensure enhanced prosperity of the community in which the complex would operate.

Under the revised CBA and after one-on-one meetings with neighbors and government officials, DGF has expanded its $5 million in dedicated funding for neighborhoods bordering the complex’s proposed location to include both the Moonshine and nearby Baytree, La., communities.

In addition to revising the CBA, DG Fuels also responded to other community and council requests, including:

- Reducing the overall project footprint by 525 acres.

- Retaining most existing farmland on the proposed project location.

- Eliminating a second border with Moonshine on its western edge.

- Moving the SAF complex to a more central location on the project site.

- Enclosing bagasse storage.

- Deferring installation of solar-power equipment for the foreseeable future.

Funding under the new CBA will support renovations to existing community health and park centers, improvements to local low-income housing developments, job training and employment opportunities, and improved medical transportation for area residents.

Project status

DGF said it expects a front-end engineering design study on the St. James Parish complex to be completed late-summer 2024, with FID on the project likely in 2025.

Based on an estimated construction and commissioning period of 3-4 years, DGF confirmed in April 2024 that the St. James Parish project would be completed sometime in 2028.

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.