Gas plant improves C3 recovery with Lean Six Sigma approach

Kamarul A. Amminudin

Thenyan S. Enezi

Mustafa A. Jubran

Ali T. Hajji

Abdulkareem S. Enizi

Zaid F. Bedoukhi

Saudi Aramco

Khurais

| Based on a presentation to 19th Annual Technical Conference of the GCC Chapter of the Gas Processors Association, May 4, 2011, Kuwait. |

Saudi Aramco's Khurais central processing plant has improved propane recovery from its gas train following performance analysis that relied on Lean Six Sigma tools. The Khurais producing department adopted the methodology, traditionally employed as a process-improvement tool throughout such non-process engineering activities as inventory management, transportation, and marketing, to address lower propane content in Khurais NGLs.

The methodology strictly follows the framework "define, measure, analyze, improve, and control" (DMAIC; see accompanying explanation, p. 106). The department defined the problem through statistical analysis of the current performance and quantification of the propane losses. The process also involved a brainstorming session to identify the potential root cause of the problem (box above).

Based on this approach, we gathered information and analyzed it to verify the root cause, identified as poor chilling performance in the gas train. We then shifted focus to improve the chiller's performance from minimizing the process stream's pressure drop across the chillers to maximizing propane refrigeration performance. The team then implemented these findings through a series of performance tests, which successfully confirmed that propane recovery can be maximized to meet the target.

Since the test was successfully completed in January 2011, followed then by ongoing monitoring, the train has sustained optimum performance to date by consistently producing a much higher NGL yield.

Khurais processing

Saudi Aramco in June 2009 commissioned the Khurais central processing plant, which lies about midway between Riyadh and Dhahran (Fig. 1). It was to produce 1.2 million b/d of Arabian Light crude oil together with associated gas and condensate from three major fields: Khurais, Abu Jiffan, and Mazalij. It also can supply water for field injection from a seawater treatment plant.

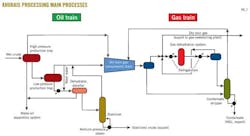

Fig. 2 shows the process flow of Khurais central processing, which includes the Khurais gas train. Crude oil from the fields is first processed in the oil train, which produces stabilized crude from a series of separation systems: the high-pressure production trap (HPPT), low-pressure production trap (LPPT), and the stabilizer. On-specification stabilized crude is then sent to the terminals for export.

The natural gas separated by the oil train is then compressed by a compression train before being sent to the Khurais gas train, which further separates it through dehydration, refrigeration, and stripping to meet a hydrocarbon dewpoint requirement. The sour-gas product from the gas train is then sent via pipeline to another gas plant for sweetening.

The condensate recovered from the gas train stripper is sent to another fractionation plant for further processing. In addition, supporting these processes is a utility system to provide steam and other utilities; power is supplied from an external source, however.

Lean Six Sigma

The Lean Six Sigma approach selected to carry out the process improvement initiative enables us to find the root cause of the problem systematically. Our goal is to ensure that the problem we are going to solve should prevent us from repeating the same problem and that the solution at hand should allow us to work towards continuous improvement.

It is common to see the Lean Six Sigma methodology applied in such nonprocess-engineering activities as inventory management, supply-chain optimization, and transportation. Chemical manufacturing companies have adopted Lean Six Sigma in many ways in their process improvement initiatives, especially when dealing with poor yield or wide variation in yield; long cycle times; and process instrumentation/controls performance.1

In a nutshell, the Lean Six Sigma approach embodies both the statistical and process tools to provide for optimization and improvement. It relies heavily on facts (data) and treats data variation as undesirable.

To address a specific process improvement initiative at the Khurais gas train, we used the Lean Six Sigma methodology to improve propane recovery from NGL products. The driving force for such an initiative is primarily the impact of product losses on the hydrocarbon chain throughout the company, especially in NGL products. In addition, operational concerns due to high liquid buildup in the gas export line following the loss of C3 product to the gas export line during the winter months made this initiative critically important.

Lean Six Sigma methodology strictly follows define, measure, analyze, improve, and control (DMAIC) phases. The project starts with problem definition, which breaks down into problem statement, project objective, and project benefits. In Lean Six Sigma methodology, understanding the problems that lead to poor performance requires a specific tool within the define phase. This involves using the supply-input-process-output-customer (SIPOC) table (above) and the process mapping diagram to gain full insight into the problem at hand.

In our case, use of the SIPOC table provides a "birds-eye view" of the process affecting the issue. This is then followed by use of a process mapping tool, a typical process flow diagram to understand in greater detail the movement of C3 in the Khurais gas train. This in turn enables the team to define the problem better.

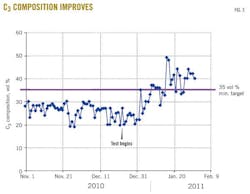

To quantify the problem, we initiated data gathering on the performance of C3 recovery. Based on data gathering for a given period, a statistical tool—Process Capability Analysis—was used on the poor C3-recovery performance from the NGL products. It was confirmed statistically that for most of the time, the C3 purity in the NGL products does not meet the minimum requirement of 35 vol %. Therefore, the team formulated the project objective to focus on improving the C3 product purity to a minimum target of 35 vol % from the then-current 25 vol %.

Finding the root cause of the problem is the next step. This is achieved by use of the following Lean Six Sigma tools: a "fishbone" diagram, cause-and-effect matrix, and failure mode and effect analysis (FMEA).

The fishbone diagram, which enables the team to explore the causes, is conducted in a brainstorming session among team members. The cause-and-effect matrix prioritizes the causes or identifies which elements contribute most to cause problem. This involves use of rankings on all elements identified as the potential of causing the problem.

Next, the FMEA, used to detail the causes, includes finding the potential failure mode, identifying the impact of this failure on the customer, identifying the potential causes of this failure, and recognizing the current control mechanism to mitigate the failure.

Each element in this FMEA analysis was rated according to FMEA rating guidelines, and the analysis was carried out in a brainstorming session. Detailed deliberation of the FMEA analysis led to the conclusion that poor chilling performance had been the root cause of the problem.

In the measure phase, all data were collected to verify the findings from the FMEA. Appropriate statistical tools, such as mean, variance, average, and standard deviation, were employed to analyze the data. In addition, a "five-why" analysis and hypothesis testing was used to verify the root cause. The accompanying box (p. 102) shows an example of a "five-why" analysis to illustrate the cause of lower C3 composition from a poor chilling performance, which is due to accumulation of solid particles in the chiller tube.

The team analysis, then, found that the causes of the lower C3 products in NGL were:

• Accumulation of solid particles that result in a significant pressure drop in the chiller tubes.

• Poor performance of propane refrigeration.

The focus then is on eliminating these causes through implementing the solution strategy.

Lean Six Sigma—a definition"Lean" manufacturing refers to a production process that expedites throughput of goods. The concepts started in the automotive industry, and the focus began and remains one of speed, gained by elimination of waste. "Six Sigma" has its roots in the semiconductor industry (Motorola) and focuses on quality, maintaining consistent quality by controlling deviations. Lean manufacturingAnything that adds no value to a product in the course of its manufacture is waste. The measure in Lean is the value-added component: Will the buyer pay for the function? Defining what the buyer actually pays for is key to identifying waste. Another area of waste elimination in Lean is reducing time spent in queue. How much time does a product "wait" along the production line for value to be added to it? Actually tightening a bolt adds value; a pile of bolts waiting to be tightened is waste. The Lean process identifies six types of waste: 1. Transportation: movement of goods that has no value. Moving goods from one step in the process to the next is necessary; moving them into a holding area to wait is wasteful. 2. Inventory: components that are merely waiting for value to be added. 3. Motion: unnecessary movement of either people or equipment. Taking 10 steps to accomplish what five will do. 4. Over production: producing more than is needed, either in parts or products. 5. Over processing: more work done to add value than results warrant. 6. Defects: time wasted in inspecting for and correcting them. Six SigmaThe last type of waste—controlling defects—is at the heart of the Six Sigma approach. This manufacturing process documents and monitors deviations. Controlling variations in Six Sigma manufacturing consists of five steps, the first letter of each make up DMAIC. 1. Define goals and processes. 2. Measure product capabilities, process capabilities, and risks. 3. Analyze to determine cause-and-effect relationships. 4. Improve the process, based on the first three steps. 5. Control the process to exclude variations that exceed acceptable standards, so that every product is of consistent quality and defect-free. Based on an explanation by Ann Deiterich, a contributor to eHow (www.eHow.com). |

Improvement

Following the recommendations of the Lean Six Sigma assessment on the low C3 recovery in NGL products, an implementation plan was carried out, the "Improve" phase of the Lean Six Sigma methodology.

First, the team wanted to confirm that the higher pressure drop in the chiller was caused by solid-particle accumulation. The opportunity came during turnaround and inspection of the Khurais gas train. An inspection of the chiller tubes' condition confirmed blockage in the tubes, and a sample of solid particles was collected for laboratory analysis. That analysis indicated the presence of iron-based materials, which originated from corrosion in the system.

The inspection team then removed these solid particles and returned the chiller to service. Improvement in the performance was noticeable but not sustainable. The team then focused on improving the propane refrigeration system itself, where the team implemented recommendations to improve the propane circulation rate and pressure setting of the propane refrigeration system.

After the plant performance test of almost a month from the end of December 2010 to the end of January 2011, a large increase in C3 purity of the NGL products was noted (Fig. 3). It also demonstrated that the composition of C3 even exceeded the minimum target of 35 vol %.

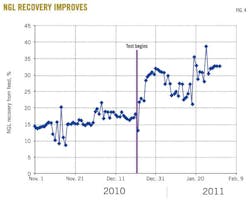

Similarly, as shown in Fig. 4, NGL yield from the Khurais gas train increased notably, corresponding to an increase in C3 purity. The yield had increased from around 16% recovery (average) initially to almost 27% recovery (average) after the improvement.

Implementation of the recommendations from the Lean Six Sigma methodology had successfully resulted in the following actual findings from the test:

• NGL yield increases by 70%.

• An increase in C3 composition in NGL to 35-40 vol % from 25 vol %.

• Relatively leaner sour-gas export, which minimizes liquid condensation in the gas pipeline.

Sustaining performance

Following this success, the team embarked on the "Control" phase in the Lean Six Sigma methodology. Its objective was to sustain the optimum performance of the Khurais gas train by continuous monitoring.

In fact, the team believes that to sustain optimum performance is the most challenging aspect in the process improvement initiative. But a concerted effort to sustain performance together with a better understanding of the process has made process monitoring with the existing process control system run smoothly. The train has achieved a stable optimum performance.

As for the long term, the team is considering installing an advanced process control system to carry out the process optimization on line. The team is working with the APC vendor to evaluate installing such a system.

The Khurais gas train has been able to sustain optimum performance, while continuously producing much higher NGL yield for the company.

Some lessons learned from this initiative are:

• Problem solving requires a very good understanding of the issues.

• The Lean Six Sigma methodology addresses issues in a systematic way through use of actual data supported by sound technical analysis.

• Efforts should be made to avoid looking at problems in silos.

• All achievements came without incurring additional cost to the organization. (Lean Six Sigma is carried out in-house without reliance on external consultants.)

Acknowledgment

The authors thank Saudi Aramco for permission to publish this article.

Reference

1. Liebermann, G., "Apply Six Sigma for Process Improvement and Problem Solving," Chemical Engineering Progress, March 2011, pp. 53-60.

The authors

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com