Production operations as a service

POaaS requires skill and efficiency to manage personnel and materials

JEFF PFERD, HALLIBURTON

PRODUCTION OPERATIONS as a service (POaaS) is a possible new business model conceived in response to disruptive oil prices, the rise of the industrial internet of things (IIoT), and practical machine learning based on massive, inexpensive cloud technology.

Traditional oilfield services include monitoring, surveillance, diagnostics, optimization, and analytics-all parts of a larger operational puzzle. However, such production fragmentation requires the operator to extract value from the individual services. Because these services are extremely valuable to operating companies, it should be possible to integrate and thereby monetize them into one complete business model. The business concept presented here assembles the fragmented production automation and optimization services into a single solution, allowing service companies to accept responsibility for operational risks in exchange for a growing share of the benefits provided by their services.

Additionally, other trends exist in the oil and gas industry. Exploration, development, and production are disaggregating into specialty companies: imaginative explorationists are locating new assets while state-of-the-art drillers leverage automation, standardization, and rationalization. Consequently, to provide production operations as a service, skill and efficiency are necessary to manage personnel and materials.

POAAS STRATEGIES

Well operators want to obtain the best production from their assets. POaaS can aid oilfield operations through the use of advanced technology, best practices, and cost savings to help maximize production and reduce risks. Strategies to increase production and control costs include the following:

• Maximize well utilization

• Apply appropriate well maintenance

• Increase safety of operations

• Efficiently allocate chemicals, tools, and equipment

• Allocate the best operators to the appropriate well and well conditions

• Introduce autonomous well operations

• Expand well operations management to other assets, leveraging skills and resources

This new business model shares risk and responsibility between service companies and asset owners while yielding a predictable return for the well owners. With a fixed-fee contract or an agreed upon decline profile, benefits obtained are directly related to POaaS performance.

DIGITALIZATION RATIONALIZATION, STANDARDIZATION

A successful POaaS requires a shift to digital business, including updated methods of working, technology, and organizational structures. New service companies need to be able to compete on price and include the use of automation and rationalization of tools and materials. Along with rationalization, they can benefit from standardization of operations and equipment for each geological terrain. Standardized models might not work for every situation, but they can be tailored to key global oil and gas terrains. Service companies need to become learning organizations, efficiently leveraging innovation across their assets.

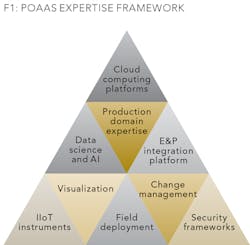

EXPERTISE FRAMEWORK FOR POAAS

In addition, they should partner with key providers of the technological components of a solution. At the core of the service capabilities is production domain expertise (Figure 1). Foundational elements include IT systems and the instrumentation provided by automation expert companies.

Production domain expertise

Production operations including surveillance, analysis, and optimization expertise is crucial to success. It is applied to each production environment.

Data science and AI

Machine learning is having an impact across industries. Oil and gas operations are moving toward predictive analytics with automated corrective actions. This leverages the production operations domain expertise.

Edge computing in the field

Edge computing analytics aids production operations by collecting data and performing analysis in real time. Automated analytical computation is performed on well sensor data. Instead of waiting for the data to be sent back to the cloud for processing, corrective actions can be applied immediately and securely in the field.

Cloud computing

Cloud computing is a scalable, powerful capability that allows field management from centralized locations and can be extended as operations grow.

Visualization

Visualization techniques present the information from the field so that operators can focus on the most important issue or opportunity.

Change management

As with all automation of work, new roles and organizations develop. The transition from current practices will require attention to change to develop a successful service.

IIoT-enabled instruments

Key to the impending changes is the arrival of IIoT enabled devices. The information provided by these instruments is processed through edge computing with predictive machine learning.

Field deployment

Technology located in the field requires deployment expertise for outdoor environments. This includes knowledge of automation and communication equipment.

Security frameworks

These closed loop systems need to be protected against incursions by cyber criminals or terrorists. Protecting the production operation systems should be built-in from the design start.

CONTRACT CONSIDERATIONS

Production goals help maintain production and control costs in a safe environment. A majority percent of asset lifetime costs and time are related to production operations. This is the business environment for which POaaS is designed. The assets are not owned by the service provider. The commercial environment is not static because of declining production rates and product prices. Such variables need to be considered in the contractual service agreement. Tracking an agreed upon decline curve and adjusting payments to an oil price moving average can share uncontrolled operational risks between the service company and asset owner.

WAY FORWARD

POaaS is a natural consequence of the significant changes and opportunities currently impacting the oil industry. The introduction of POaaS will be disruptive to the participating organizations. Asset owners need to reduce operational costs, and POaaS providers need to organize around the expertise framework. These changes are the greatest barriers to implementing POaaS in traditional organizations.

For this reason, the POaaS model might instead emerge from consortiums that exist outside of current operators and service companies. These POaaS providers could develop the new integrated operations without the difficulties resulting from the destruction of solution silos in current service companies. New asset owners can view producing assets as an annuity and focus primarily on the financial agreements. They do not have to transition from organizations focused on operations.

This approach could begin in unconventional assets, which operate with a manufacturing operational style. For such resources, the POaaS approach could increase their value and market accessibility.

ABOUT THE AUTHOR

Jeff Pferd, PhD, is a senior member of the Halliburton Information Management team with more than 25 years' experience in the oil and gas industry. His background combines scientific domain knowledge and advanced technology.