Are your trains coming or going?

Developing the blueprint for crude by rail

Patrick Long and Steve Roberts, Opportune, Houston

Crude by rail, a topic that five years ago was virtually non-existent, now plays a significant role in the North American oil boom. Trains delivered 11% of crude produced in the US in the first three quarters of 2013, up from nearly zero in 2009.

If you are a producer, refiner, or physical trader, rail is a serious logistics option, and can represent a black box of operational and process risks that need to be considered. As organizations integrate rail optionality into their overall supply chain strategy, few appreciate the full operational and financial impacts of the decision and initiate the change necessary to robustly manage rail in a manner necessary to fully capture potential value.

Added to the mix in the last 12 months are the complexities of increased rail traffic, high-profile safety incidents leading to potential regulatory and legislative changes, and weather disruptions that can bring all transit to a halt. These issues create fear and uncertainty and bring along with them increased operational risk and costs that, if left unmanaged, can undermine the economic advantage of crude rail transport.

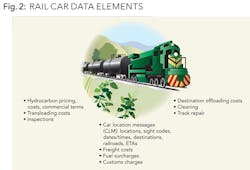

In addition to understanding rail operations, it is essential that companies gain visibility to all of the fixed and variable costs. Only then will companies achieve actionable insight.

Transforming data into insights

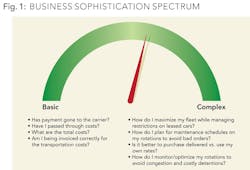

Given the dramatic increase in the energy industry's use of rail, is your organization prepared? Where is your organization along the financial analysis and margin optimization spectrum?

The flexibility of rail presents organizations with a deluge of data. Instead of tracking two million barrels on a Very Large Crude Carrier (VLCC), organizations are forced to track the equivalent of 500 to 700 barrels per rail car, times tens of thousands of cars.

At the start of the rail uptick, the focus was on securing as many rail cars as possible – purchase or lease – and to get them on-line. Then, as cars entered service, new owners started to realize the various complexities of managing the assets:

- lease payments

- mileage restrictions

- maintenance and repair schedules

- coiled vs non-coiled

- fees associated with origin loading and destination discharge

- interfacing with railroads

- managing detention and demurrage

- surcharge for older, DOT-111S, tank cars

- potential for fees for transporting through urban areas

- insurance, safety

Isolated, organizations can manage these pieces. Coupled together, the complexities present challenges, especially when multiplied by thousands of cars in service.

The basic issue

The issue is not the physical assets themselves. Organizations will turn to experts and companies to handle all of the primary and ancillary services required to maintain a leased or owned fleet and move rail cars from one point to another. The issue is data. Rail cars generate a lot of data.

Take the simple analogy of a crude purchaser accustomed to bringing in the majority of crude via marine movements. Even with lightering, each movement can be around 300,000 barrels. Assume each railcar has as many pertinent data points necessary for the full deal lifecycle as a barge. The data volume multiplies by at least 400. The processes around each individual type of data may be similar, but the sheer amount of data necessitates new approaches, processes, and possibly even systems.

Organizations – as they focus on pure operational/logistical challenges -- are blissfully unaware initially at the power of this information when they embark on fleet expansion. They may be aware of the data. They may use a combination of spreadsheets and data warehouses to track and store it. The immense amount of data surging through the combination of systems provides many with – at best – an uneasy feeling and – at worst – an unmanageable and financially unsustainable supply strategy.

Market participants may be aware of the power of rail data but are unable to tap into and exploit it. They want to ask it questions and get answers for the organization, but are unaware of how to do it. Therefore, since organizations, like the human brain, can consume only so much, they just skim the surface and gather a scant amount of data to manage their operations. Even while they settle into an organizational routine of only focusing on the data that is most obvious and pertinent to transactional needs, immense amounts pass by the organization.

Inertia is powerful. The forces are strong for an organization to not take action and ignore the very data that it needs. Old habits need a trigger to force change, and the similarity of rail to existing processes can fail to produce the trigger. Unfortunately, a trigger is often forced through a painful event – unexpected costs, operational disruption, or loss of business efficiency as resources are mired in data with no real information.

How do organizations survive (and ultimately thrive)?

Survival is the basic operational mindset of shippers as cars and their logistical needs overwhelm an organization.

For each planned railcar trip from Canada to the East Coast, there are estimated costs based on railcar, carrier, product, and other potential factors. As the railcar travels to the destination, a number of other costs can emerge and eventually be invoiced. In response, the rail company will send an invoice for that railcar trip. At each point in the process from planning and scheduling to invoice payment, there are options to review and balance cost against business needs. While the data is available to support the decision-making process, many organizations do not effectively transform it into information in manner timely enough to facilitate the decision-making process.

Massive spreadsheets track the many details in hopes of preventing unexpected losses and costs. In order to reap the value from rail operations, organizations must force the transition to straight-through processing and allow the management of exceptions to become routine. Accomplishing this goal takes steps beyond basic process and system changes. The deluge of data needs to be corralled into new processes and potentially systems, and then the data needs to be interpreted into near real-time, actionable information.

For many organizations, the challenge of scaling a crude by rail strategy represents a classic ‘big data' problem: there is a wealth of data available, but frequently in different formats, from different systems, at different levels of aggregation and with no straightforward manner of traversing the data across the value chain. Initial stimulus response is to put all of the data in a spreadsheet and start digging away.

In order to avoid siloed information, disconnected from an efficient process, a business insight solution can be employed. A robust, rapid-to-deploy analytic solution can connect seamlessly to different data streams simultaneously, join the data at each stream's native level of detail, and provide a view into the interactions. Correctly configured, a solution can be utilized by scheduling and operations to do "what-if" margin optimization planning, mid-office to track railcars as they progress through their trips, and back-office to reconcile and forecast expenses.

Now, extend this across all of the following data: operations, hydrocarbon trading, asset maintenance, and payable and receivable invoicing – the potential margin expansion value explodes. A comprehensive analytics solution provides visibility into the data otherwise lost in the transactional systems necessary to keep the daily business running. Such business insights allow organizations to see the light at the end of the tunnel, and have the confidence to know it is not a train headed toward them.

Set your sights and keep focused

So where is your organization now? Assess your company's need and current ability. Some organizations have the capacity to consume, understand, and incorporate the information into the business process. Other organizations are overwhelmed by the data and focused on other pressing business issues. Determine where your organization is now versus where you are targeting in the future – vision a bit as to where you could be in a ‘perfect' world where all rail data is unleashed and presented in a manner to allow for near real-time, optimal decisions.

Develop the blueprint that combines strategy with business processes, organizational change, and the necessary systems to enable your organization to achieve the necessary goals for the future. Finally, execute to drive value to the organization. Provide relief to your business and start making evidence-based decisions from meaningful insight. Infuse business intelligence into the larger culture of the organization.

About the authors

Steve Roberts is a director in the Process and Technology practice for Opportune LLP, a consulting firm specializing in energy clients headquartered in Houston. He has almost 15 years' experience consulting in the energy industry, serving global super-major integrated oil companies, independent refiners, petrochemical manufacturers, and logistics companies. Roberts' focus is on supply, trading, and logistics.

Patrick Long is a director with Opportune's Process and Technology Practice. He co-leads Opportune's Business Intelligence Practice. He has been consulting for 17 years with oil and gas clients in energy trading risk management. His background spans midstream and downstream clients in predominantly oil and gas and liquids. Long's focus is helping clients solve complex business issues through an intelligence use of their data to achieve insight and actionable results.