Nugget hardfacing toughens roller cone bits

This 97/8-in. IADC 117M friction bearing bit has nugget hardfacing (Fig. 1).

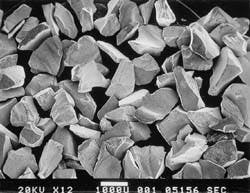

Homogeneous nuggets of tungsten carbide particles (right) allow a more controlled deposit on bits, eliminating potential void spaces and irregularities caused by conventional particles (Fig. 3 and 3a).

A new hardfacing material made of pure sintered tungsten carbide nuggets has improved roller cone rock bit performance in extremely hard lithologies, increasing penetration rates and extending bit life through multiple formations.

In one particular application, the hardfacing improved bit performance and helped eliminate at least one round trip that would have been needed to change to an insert bit.

In a recent test run in the Shushufindi 95 well in Ecuador, a Security DBS 97/8-in. MPSF IADC 117M (International Association of Drilling Contractors bit code) bit with this new hardfacing drilled out the float equipment, cement, and shoe and then 3,309 ft of hard formations (Fig. 1). The bit drilled through the Orteguaza clay stone/

shale/ sand and chert formations and then to total depth at 6,309 ft in the Tiyuyacu shale/sand. The 3,309-ft interval was drilled at an average penetration rate (ROP) of 52.5 ft/hr (Fig. 2 [27312 bytes]).

The abrasive Orteguaza formation (2,583 ft) was drilled in 30.8 hr, with operating parameters reaching a maximum speed of 170 rpm, 700 gpm flow rate, and 40,000 lb weight on bit. The penetration rate of 83.9 ft/hr through this section is a significant increase over the average penetration rate of 77.4 ft/hr for a typical IADC 117M bit used in this formation.

Typically in this field, new bits are introduced to drill through the subsequent 696 ft of hard chert stringers. The MPSF 117M bit drilled the hard chert section with an average penetration rate of 23.3 ft/hr. This rate matched that of new insert bits run through the chert. The operating parameters were held to 60 rpm, 440 gpm flow rate, and 35,000 lb weight on bit.

The new hardfacing extended the bit life so one bit could drill the entire interval, saving the cost of a new insert bit and the round trip time, according to Security DBS.

After the bit reached total depth and was pulled, it was dull graded at three for both inner and outer row teeth, with overall wear graded seven of a possible eight, indicating maximum wear. The primary dull characteristic was flattened crest wear (FC) and the secondary characteristic was worn teeth (WT).

Nugget hardfacing

The oxygen acetylene hardfacing, TECH2000, consists of nugget-shaped particles of pure sintered tungsten carbide which replace standard tungsten carbide particles in conventional tube rod compositions.

The nugget structure provides a consistent shape and controllable particle size for more uniform distribution within the hardfacing matrix. Conventional particles are made by crushing sintered parts, which produces varying sizes of particles with varying amounts of cobalt. In contrast, the nugget material is actually pressed and sintered as particles in a process using a controlled amount of cobalt, providing a more homogeneous material.

This homogeneity allows better control of the amount of material packed into a hardfacing rod and delivered to the deposit, eliminating the potential for void spaces which result from inconsistency in the size of conventional particles, according to Security DBS. In addition, the improved hardfacing deposit further enhances wear resistance of the welded material.

The proprietary nugget material was tested according to the American Society for Testing Materials (ASTM) G65 wear test method, a standard industry method of measuring wear resistance. The nugget material had ASTM wear test resistance more than twice that of standard hardfacing from conventional tungsten carbide.

Copyright 1996 Oil & Gas Journal. All Rights Reserved.