Natural Gas and Electricity Rise In Gas-Fired Power Generation Tracks Gains In Turbine Efficiency

Paul Bautista

Gas Research Institute

Chicago

Industrial gas turbines, such as this GE engine model 7FA, are designed for stationary uses that include power generation. Advances in turbine technology, along with supply security and moderate prices, have made natural gas competitive as a primary fuel for electricity generation. Further advances are coming. Photo courtesy of Gas Research Institute and GE Power Systems.

Natural gas-fueled gas turbines-in both simple and combined-cycle configurations-will account for most power generation capacity additions through 2000. It is widely agreed that gas turbines will remain the dominant form of technology for power generation for the next decade or two, making them the "power generation technology of choice" for today and the future.

The pre-eminent stature of gas turbines can be attributed to their low capital costs, high efficiency, low emissions, short permitting and construction lead times, and proven reliability. The versatility of gas turbines also makes them unique among power generation technologies, as they can economically serve a wide spectrum of applications and sizes-from distributed generation to industrial cogeneration and central station generation.

Three primary factors contribute to the growing interest in gas turbine-based power generation and the role gas turbines will play in the future power generation market:

An optimistic outlook for the supply and price of natural gas.

Technology advances that have produced substantial improvements in efficiency and emissions.

Emissions regulations that may favor the use of gas turbines over traditional fossil-fueled steam turbines.

Gas supply, price

Increased U.S. use of natural gas as a fuel for electric generation has come at a time of readily available, competitively priced gas supply. In fact, deregulation and restructuring of the natural gas industry have contributed to significant declines in natural gas prices for large customers such as electric power generators (Fig. 1 [40716 bytes] and Fig. 2 [38983 bytes]).

The price scenario is not likely to change. Forecasts by the U.S. Department of Energy, Gas Research Institute, and others see only small increases in gas prices over the near and long terms. Continued technology advances in locating and processing natural gas, such as gas under deep water, coalbed methane, and gas from tight sands, have bolstered gas supply to levels that will be more than adequate to meet long-term demand at competitive prices in traditional gas markets as well as in such growth markets as power generation.

Gas turbine technology

Gas turbines can be classified under two broad categories: industrial and aeroderivative. With advanced, new machines, however, special design features have blurred many attributes that have traditionally distinguished each machine type.

Industrial gas turbines (sometimes referred to as heavy-duty or frame machines) are designed specifically for stationary applications such as power generation and compressor drive. Major manufacturers of industrial gas turbines are General Electric, Westinghouse, ABB, Siemens, and Solar Turbines.

Since industrial gas turbines were never intended to power aircraft, weight and aerodynamic drag are not constraints. They are designed with heavy compressor and turbine blades, turbine buckets, and turbine nozzles and are housed in rugged casings and frames. Industrial machines are available in sizes ranging from 1 to 230 megawatts (mw) for both 50 and 60 hz service.

Traditional characteristics of industrial gas turbines included moderate pressure ratios (6:1 to 15:1), firing temperatures below 2,300° F., and high exhaust temperatures (approximately 1,000° F.), resulting in moderate simple-cycle efficiencies (28-32% lower heating value, or LHV) and relatively low capital costs on a dollar-per-kilowatt basis ($200-400/kw for simple cycle and $500-700/kw for combined cycle). These characteristics make the industrial machines well-suited for lower capacity factor applications in simple-cycle configurations as well as for baseload applications when coupled to a heat recovery steam generator and steam turbine to comprise a combined cycle, capable of efficiencies greater than 55% LHV.

However, recent technology developments by industrial gas turbine manufacturers have produced advanced machines that deliver dramatic improvements in efficiency and emissions. ABB's GT24/26, Westinghouse's 501G, and GE's Frame 7G & H now feature innovative technologies, such as sequential combustion (also referred to as reheat), pressure ratios approaching 30:1, turbine inlet temperatures of 2,600° F., and closed-loop steam cooling that provides simple-cycle efficiencies of nearly 40% LHV and combined cycle efficiencies approaching 60% LHV.

Aeroderivative gas turbines were first designed as aircraft engines and later modified for stationary operation. Major manufacturers are GE, Rolls Royce, UTC-Turbopower & Marine, and Allison Engine Co.

Aeroderivative gas turbine technology capitalizes on extensive research and development investments in aircraft turbines, as well as their production volumes. In fact, gas turbine development for both aeroderivative and industrial power generation has been strongly influenced by development of gas turbines for military and civil aircraft. Advanced blade cooling, directionally solidified and single crystal blading, advanced coatings, and three-dimensional blade profiles have all come to power generation via this route.

Aeroderivative gas turbines are currently limited in size to 50 mw and are lighter and smaller than industrial gas turbines. Characteristics of aeroderivatives include pressure ratios as high as 35:1, higher firing temperatures than industrial machines, and lower exhaust temperatures (approximately 700° F.) that result in higher simple-cycle efficiencies (32-42% LHV) and somewhat higher costs than industrial gas turbines.

The most noteworthy of the recent aeroderivative products are the Rolls-Royce Industrial Trent and the uprating of the GE LM6000.

The Trent is the largest aeroderivative gas turbine available today at 51 mw and has an efficiency of 42% LHV. It is based on the successful Trent 800 aircraft engine. Likewise, GE is offering uprated models of its popular LM6000 gas turbine, which features shaft output as high as 44 mw and efficiency of 42% LHV.

Efficiency improvements

One of the most powerful means of achieving higher gas turbine efficiency is raising turbine inlet temperature (also referred to as firing temperature). Higher turbine inlet temperatures increase the efficiency of the simple cycle as well as the combined cycle.

If current techniques were followed, higher turbine inlet temperatures would require increases in the cooling flow to maintain acceptable temperature levels in hot sections. Historically, turbine inlet temperatures have improved incrementally with advanced materials and cooling schemes. These improvements allow the current offering of advanced machines to achieve high performance levels without sacrificing reliability, durability, and part life.

Various approaches allow for increased turbine inlet temperatures while retaining the desired durability and reliability of hot-section hardware. Among the approaches are thermal barrier coatings, advanced cooling techniques, and high-temperature materials.

Cooling flows and methods of cooling have a major impact on cycle efficiency because the amount of air used for cooling has a negative influence on both the power output and turbine efficiency. Higher cooling flows also lower gas turbine exhaust temperatures, resulting in decreased gas turbine exhaust and, consequently, reductions in the amount of steam produced in combined-cycle applications. Im proved cooling systems, similar to those in aircraft turbines, have been applied to the F-class machines to increase cooling effectiveness and reduce demand for cooling air. This has generated substantial increases in efficiency.

In addition to advanced cooling schemes, the use of closed-loop steam cooling is included in combined-cycle configurations of the GE Frame 7 and 9 H machines and the Westinghouse 501G. Steam is readily available in these combined-cycle configurations, and the heat transfer and heat capacity coefficients are nearly double that of air.

Ceramics, which are capable of withstanding extremely high temperatures, also hold promise for higher turbine inlet temperatures. Ceramics are currently being evaluated in small industrial gas turbines for stationary components, such as combustor liners.

As part of a U.S. Department of Energy program, Solar Turbines has retrofitted a Centaur 50 gas turbine with ceramic first-stage blades, nozzle, and combustor liner. This application allows for a 200° F. increase in firing temperature and a corresponding 5.7% increase in efficiency.

Documentation is still needed to prove the long-term durability of ceramics at high temperature and cycling application. Although a commercial application is several years away, development and integration of ceramic components continue to offer promise of further efficiency gains.

Intercooling, reheat

While higher turbine inlet temperatures have been the classical means of improving thermal efficiency, turbine manufacturers are also achieving efficiency gains by modifying the thermodynamic cycle (including intercooling and reheat).

"Intercooling" refers to the cooling of air at intermediate points during the compression process to increase gas turbine output by significantly lowering the parasitic power consumption of the compressor. Intercooling itself does not improve efficiency, but lower-temperature cooling air allows for higher turbine inlet temperatures that deliver higher efficiency.

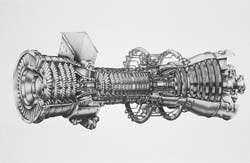

Aeroderivative gas turbines, such as the GE LM6000 in this rendering, have benefited from research and development conducted for aircraft engines.

Aeroderivative gas turbines are especially attractive for intercooling because of their multiple-spool design and high pressure ratios. An intercooled aeroderivative (ICAD) in a simple-cycle configuration can deliver efficiencies that exceed 45% LHV, with output increased to more than 100 mw, depending on the specific design and manufacturer. With costs slightly above traditional simple-cycle industrial peaking units and efficiencies just below advanced combine cycles, the ICAD seems well-suited to intermediate load applications.

Electric and gas companies and research organizations, including GRI, have formed an international consortium, the Collaborative Advanced Gas Turbine Program, to help accelerate the commercial availability of high-efficiency ICADs for power generation. The program, conducted in cooperation with aeroderivative gas turbine manufacturers (GE, Pratt & Whitney, and Rolls-Royce), has helped establish the ICAD as a viable gas turbine product for intermediate load applications. These applications include high simple-cycle efficiency as well as quick and frequent starting applications, without imposing a significant maintenance-cost penalty. The consortium hopes to support a launch order for 10-15 projects, which ICAD suppliers have indicated is needed to proceed with development.

Reheat is also being pursued as a way to increase work output and efficiency. Reheat can be described as staged expansion of hot compressed gas with reduced enthalpy being restored by refiring between expansion stages. A reheat combustor is equivalent to reheating steam in a Rankine cycle, a standard practice in modern utility steam plants, and is similar in principle to an afterburner on a jet engine.

ABB has implemented reheat in its GT24/26 machines (Sequential Combustion System) as a way to increase combined cycle efficiency (58% LHV) without the added risk of going to higher turbine inlet temperatures. ABB expects higher availability from this approach versus moving in the direction of higher firing temperatures.

Emission regulation, control

Oxides of nitrogen (NOx) are the primary pollution of concern for gas turbines.

More stringent air quality regulations, including the Clean Air Act Amendments of 1990, have increased the importance of emissions control for both existing and new gas turbines. Under Title I of the amendments, national ambient air quality standards (Naaqs) set limits on the maximum allowable ambient concentrations of major pollutants. Areas are classified as being in attainment or in various degrees of nonattainment. Nonattainment classification means that lowest achievable emissions rate (LAER) controls for NOx and NOx offsets will be required for new units in those areas, and reasonably available control technology (RACT) is required to be retrofitted on "major" existing emissions sources.

Prevention of significant deterioration (PSD) of air quality is required in areas in attainment. New emission sources are required to use best available control technology (BACT) and limit emissions so that the increased ground-level ambient concentrations of a pollutant do not exceed the Naaqs as a result of the new source.

Given this alphabet soup of environmental regulations, cost-effective emissions control techniques are needed to meet regulations in cost-effective ways that do not compromise typical operations or performance. To date, the most common control technology has been the injection of either water or steam to reduce flame temperature and subsequently lower the NOx formation rate.

However, this diluent injection imposes a related performance penalty in combined cycle and may increase carbon monoxide emissions substantially with higher injection rates. Operators are also forced to deal with other issues such as the cost, availability, and purity of water.

Postcombustion catalytic systems, although expensive, have delivered single-digit emissions.

In addition, many gas turbines installed in ozone nonattainment areas require use of selective catalytic reduction (SCR). In the SCR process, ammonia is injected into the exhaust and, in the presence of a catalyst, reacts with NOx to form elemental nitrogen and water. Major problems with SCR include exceedingly high capital costs (especially on a specific dollar-per-kilowatt basis for units smaller than 20 mw), ammonia slip, handling and storage of ammonia, and the disposal of spent catalyst.

Manufacturers and owners of gas turbine systems have long recognized that improved emissions abatement methods are needed to overcome the shortcomings and cost penalties of water injection and SCR. For the past several years, gas turbine manufacturers have pursued the development and commercial availability of advanced dry combustion systems to reduce the overall operating cost of gas turbines required to meet racheting emissions restrictions.

Among the developments are dry low-NOx (DLN) combustors. Hardware may vary significantly from manufacturer to manufacturer, but the same principle is used to achieve lower NOx emissions without water injection. Low-NOx combustors reduce peak flame temperatures by mixing fuel and air before combustion and keeping the fuel-to-air ratio as low (lean) as possible. This inhibits the formation of NOx through thermal fixation of atmospheric nitrogen.

In the conventional diffusion flame combustor, fuel-air mixing and combustion occur simultaneously, resulting in local fuel-air mixture nonuniformities that can produce high local temperatures that contribute significantly to NOx. In commercially available DLN configurations, 9 ppm or 15% O2 has been achieved in large utility-scale systems, and 25 ppm has been recorded in smaller industrial-scale systems.

Further improvements in combustion technology are being pursued that will further reduce NOx emissions, including "ultra-lean" premix, which pushes the limits of lean premix, and catalytic combustion. Innovative combustion technology may be needed as the drive for higher efficiency forces even higher turbine inlet temperatures.

In catalytic combustion, the presence of a catalyst allows fuel to burn at temperatures below levels at which significant NOx quantities are formed. Past efforts at developing catalytic combustors for gas turbines have achieved low single-digit NOx levels but have failed to produce combustion systems with suitable operating lifetimes. This is typically attributable to high-temperature and cycling damage and to the brittle nature of materials used for catalysts and catalyst support systems. Currently, manufacturers are testing new, nonbrittle metal catalytic systems that may overcome the problems that have plagued past efforts.

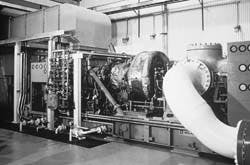

Dry, low-NOx combustors reduce combustion temperatures by mixing fuel and air before combustion and keeping the mixture as uniformly lean as possible. This unit is from Solar Turbines.

More advances coming

Gas turbine based-systems, in both simple and combined cycle configurations, are currently positioned as the "power generation technology of choice" in the rapidly changing electric power industry.

Their low capital cost, high efficiency, low emissions, short lead times, proven reliability, and flexibility of use in a wide variety of small and large power generation applications make them highly valued in the competitive power industry.

Strong alliances between gas turbine manufacturers and gas and electric utilities are ensuring that additional technology advances in systems performance and emissions reduction will be achieved in the near future that will improve upon the competitive position of natural gas-fueled turbine systems.

The Author

Paul Bautista is program team leader, Power Generation Business Unit, at Gas Research Institute, responsible for management of GRI's distributed generation program and gas turbine-related activities. Before joining GRI in 1991, Bautista worked for GE Aircraft Engines in Lynn, Mass., where he held positions in project, design, and production engineering.

He has a bachelor's degree in aerospace engineering from the University of Michigan, and a master's degree in engineering management from Northwestern University.

Copyright 1996 Oil & Gas Journal. All Rights Reserved.