Field trials demonstrate microbes extend oil production longevity

Chang Hong Gao

American University of Ras Al Khaimah

Ras Al Khaimah, UAE

Oil companies inject live organisms and nutrients into reservoirs to mobilize residual oil through microbial enhanced oil recovery (MEOR) in efforts to improve oil production and extend production longevity.

MEOR projects across the US, Canada, and Asia have increased oil recovery rates for complex reservoirs. Table 1 shows a summary of MEOR case studies mentioned in this article.

About 70% of treated wells demonstrated positive responses and all projects were profitable. Traditionally, high temperature and high salinity have prohibited MEOR applications.

Enhanced oil recovery (EOR) specialists used MEOR in low-permeability formations, high-salinity reservoirs, high-temperature reservoirs, and heavy-oil fields.

MOER effectiveness depends on proper bacteria and EOR field practices. Bacteria strains must be selected that prosper in the specific reservoir.

Petroleum engineers estimate more than 50% of original oil remains underground at field abandonment. Commercial EOR methods include steam injection, polymer injection, and CO2 injection.

Bacteria and metabolic products, such as biosurfactants and biopolymers, mobilize oil in the reservoir. If favorable bacteria exist already in the reservoir, only nutrients need to be injected. MEOR involves natural, environmentally friendly products, no major modification of water injection equipment, and low energy consumption.

However, MEOR has yet to gain broad field application. Some factors limiting its implementation include:

• Bacteria cannot survive under very high temperature so MEOR usually is excluded from high-temperature reservoirs.

• High salinity formation water, found in many reservoirs, restricts microbe growth.

• Heavy components in crude oil, such as asphaltene and bitumen, are toxic to microbes.

• Exogenous bacteria injected into the reservoir compete with endogenous bacteria.

• Various chemicals injected into the reservoir, including acids, polymers, and surfactants, can hinder microbial activities.

MEOR mechanisms

Certain bacteria produce surfactants, polymers, gases, and solvents that mobilize oil in the reservoir. Many experimental studies have focused on MEOR mechanisms such as reduction in interfacial tension (IFT), permeability modification (or selective plugging), reduction in oil viscosity, alteration of wettability, and biodegradation.

This article focuses on MEOR field applications rather than mechanisms, which are outlined extensively in other literature (Oil and Gas Journal, Aug. 17, 2009, p. 39).

Certain bacteria produce biosurfactants that reduce oil-water interfacial tension. Residual oil is held in porous rocks by capillary pressure, which is proportional to the interfacial tension (IFT) between oil and water.

When IFT is reduced to a much lower value, residual oil flows. IFT fell from 60 to 0.0012 Newton/m (N/m) due to microbial metabolism.

During water flooding, most injected water flows into larger pores while residual oil remains in small pores without being swept.

Bacteria also tends to enter large pores. The bacteria, or the biopolymers they generate, can plug high-permeability zones within large pores, forcing injected water to sweep the oil in low-permeability zones.

Certain bacteria produce gas, organic acids, and solvents in the reservoir. Gases, such as methane and carbon dioxide, and solvents can dissolve in crude oil, reducing viscosity.

Microbes have reduced heavy oil viscosity by more than 50% in laboratory tests. Lower oil viscosity improves mobility ratio and oil recovery.

In an experimental study, researchers observed microbes produced large quantities of produced gas, which can increase reservoir pressure and production.

Some bacteria can degrade or remove paraffin in crude oil, improving permeability and increasing production.

Bacteria injection can happen through production wells (producers) or water injection wells (injectors). Most MEOR projects are classified as huff and puff or microbial flooding depending on the injection method. For huff and puff, bacteria are injected into the reservoir through producers, which are shut in for days before production resumes.

For microbial flooding, EOR crews inject bacteria through injector wells, and the bacteria works its way to the producing wells.

US, Canada fields

Five US and Canada fields, operated by Husky Energy, received nutrient injections to activate indigenous microbes. Table 2 shows the rock type and fluid properties involved.

Sparky field and Upper Topanga field produced relatively heavy oil, while the high-salinity Devonian field produced relatively light oil. During 2007-10, 35 producers and 30 injectors received treatment across five fields. About 80% of wells showed positive responses.

Producer wells increased production by a combined 205%. Field cases demonstrated MEOR was effective in treating both light and heavy oil reservoirs. MEOR worked well in the HT Hauser field.

Indonesia huff and puff

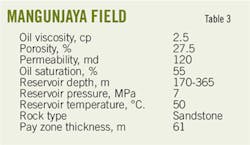

Mangunjaya field, operated by Pertamina, has produced for 80 years. Oil recovery reached 40% while water cut reached 78%. Table 3 shows Mangunjaya field reservoir parameters.

In 2015, wells MJ-122 and MJ-155 received microbial huff and puff. Crews flushed the wells with brine before and after the wells were injected with microbes and nutrients. The wells were shut in for 7 days. The water cut dropped to 50% from 95% in about 3 months while liquid production increased 17%.

China field cases

Many of the case studies involved fields in China, where usually a slug of polymer or nutrient was injected in front of the bacteria to protect it.

Favorable reservoir conditions led to using microbial huff and puff on 518 wells in 10 blocks at China’s Daqing field. The treatment resulted in 63,386 tonnes of incremental oil production.

Daqing, operated by China National Petroleum Corp. (CNPC), produces relatively light oil under moderate reservoir temperature.

Bohetai block is a low-permeability reservoir, having a range of 1-50 md. In 2002, 13 production wells received huff and puff involving a mixture of five bacteria strains. Ten wells responded positively.

Wells were shut in for 7 days after injection. Viscosity of produced fluid dropped to 57 cp from 101 cp. Wax content declined 1-5% while the oil-water interfacial tension fell 40%. Water cut dropped to 44% from 61%. An estimated 2,138 tonnes of extra oil was produced over 2 years. The highest-permeability well had the best output. The oil rate increased from 0.4 tonnes/day before the treatment to 5.2 t/d afterward. In 2003, a second round of bacterial huff and puff was applied to four wells.

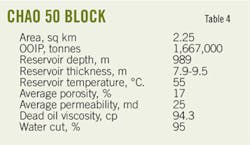

After Bohetai block trials, Chao 50 block received bacterial injections from June 2004 to February 2005. Table 4 shows the properties of Chao 50’s tight reservoir.

EOR specialists recommend MEOR for permeability higher than 50 md, but the average permeability was only 25 md for this reservoir. The block involved 10 producers and two injectors. Brevibacillus brevis and Bacillus cereus were the bacteria chosen for injection. Their sizes were around 0.8 × 1.4 μm and 0.4 × 1.0 μm, respectively. The average pore throat size was 2.3 μm. High microbe concentrations in produced fluid confirmed bacteria moved through the pores.

After injecting 250 tonnes of bacterial fluid, seven producer wells responded positively to microbial injection. Liquid output increased to 1,456 tonnes/month (t/m) from 957 t/m.

Monthly oil production climbed to 843 t/m from 361 t/m. The water cut dropped to 38.6% from 95%. Engineers estimated incremental oil production at 13,600 tonnes over 4 years.

Oil quality also improved, with viscosity dropping 20% to 76 cp. The paraffin content dropped 5% to 7.6%. The interfacial tension dropped 14% to 0.04 N/m.

Producing wells near the injection wells demonstrated the best results. The Chao 50 trial proved MEOR can be effective for very tight formations.

Microbial EOR spread to 60 wells in the block, while 43 wells saw positive feedback with 9,175 tonnes of additional oil production.

China’s Shengli field, operated by Sinopec, features complex geologies and a diversified reservoir that has produced more than 1 billion tonnes of oil since its 1961 discovery. Water flooding, polymer flooding, and steam flooding are common.

EOR crews implemented microbial huff and puff on 1,640 wells. The EOR contributed 219,000 tonnes of additional oil production since the 1990s.

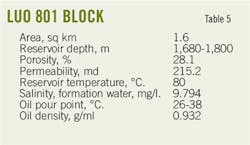

Table 5 shows the Luo 801 block produced heavy oil with 11% recovery after rock expansion and solution gas drive. The oil became more viscous after the solution gas was liberated.

In 1994, the viscosity from Well 805 was 189 cp. In 1998, oil viscosity climbed to 725 cp. Oil production from the block decreased to 200 t/d from 472 t/d.

In 1998, crews injected bacteria through four injector wells connected to 11 production wells. After bacterial flooding, production climbed to more than 300 t/d. Engineers estimated around 43,500 tonnes of extra oil was produced during 1998 to 2004.

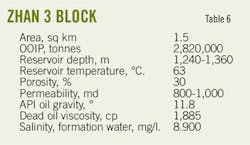

Zhan 3 heavy oil block has received water injection since 1989. Oil recovery reached 25% after 22 years of water injection and the water-cut reached as high as 92%. The block contains 13 producers and five injectors.

Table 6 lists Zahn 3’s reservoir parameters. Three production wells received nutrients but no bacteria. After wells were shut in for 1 week, oil production increased (10.4 t/d from 3.4 t/d), and the water cut decreased to 88% from 93%. The successful pilot led to expanded trials at the field.

During 2011 through December 2014, a total of 5,997 tonnes of nutrients was injected, resulting in 27,000 tonnes of additional oil output.

Xinjiang field in west China is operated by CNPC. Fourteen wells at Xinjiang field received bacterial treatments during September 2007-August 2008.

Laboratory work demonstrated the selected microbes could emulsify heavy oil and significantly reduce oil viscosity. For the field trial, workers cleaned the wells with steam to remove wax and debris.

After bacterial fluid was injected, the wells were shut in 2-3 days. Twelve wells showed positive responses, producing 1,535 tonnes of extra oil over 2 years.

In 2014, the 7-Zhong block was selected for nutrient injection without receiving exogenous bacteria. The block has four injectors and 11 producers. The block’s original oil in place was 719,000 tonnes and oil recovery reached 41% before treatment. The injected nutrient contained sugar, sodium nitrate, and ammonium phosphate.

Nutrient injection lasted 1.5 years, with total injection volume of 0.1 pore volume (PV). About 3 months after the treatments started, all 11 wells showed positive feedback, while the number of bacteria in the produced water escalated to 108/ml. Total oil production climbed to 41 t/d from 14 t/d. The water cut dropped to 81% from 90%. Additional oil production was estimated at 21,513 tonnes during 2014-17.

CNPC operates Liaohe field in northeast China. Before MEOR in the field, researchers studied two bacterial strains in the laboratory, concluding the strains produced surfactants that could emulsify heavy oil. The bacteria grew best at 37-55° C.

Crews started the Liaohe field trial in September 2005, injecting 13 producers on Jin 45 and Qian 12 blocks with bacteria.

The blocks had received steam flooding for more than 10 years, but its effect had weakened before bacterial treatment began. The wells produced heavy oil with viscosity of over 5,000 cp at surface.

After the bacteria injection, the wells were shut in 7-9 days. As of February 2006, 12 wells showed positive response and produced 2,511 tonnes of additional oil. The trial proved MEOR was more cost-effective than steam flooding. For instance, steam flooding in Well Jin 45 to produce 1 tonne of oil cost cost 863 CNY while the cost with bacteria was only 339 CNY.

Leng 43 block at Liaohe field produced very heavy oil. Crude oil density was 0.97 g/ml and its viscosity was 9,620-43,000 cp at 50º C. Salinity was low at 5,435 mg/l.

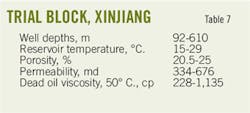

Table 7 lists the reservoir parameters for a trial block in Xinjiang. Five producers were selected for microbial huff and puff.

Before the treatment, the five wells received steam injection, but with poor production. The wells first received nutrient fluid through casing-tubing annulus, followed by a mixture of bacteria and nutrient, and then a slug of nutrient. The wells were next shut in for 7 days. After production resumed, four wells increased oil production and decreased water-cut by 10%. An additional 530 tonnes of oil was produced in 1 year. Fifth-well liquid production increased significantly, but the oil rate was almost the same as before.

Jing 35 block is a shallow, heavy oil reservoir. Its low reservoir temperature hinders oil flow. As a result, the recovery factor was only 4.3% until 2012. Three cycles of microbial huff and puff were conducted on six production wells in 2013.

Three bacteria strains were selected: Geobacillus stearothermophilus, Geobacillus thermodenitrificans, and Pseudomonas aeruginosa.

Five of six wells reported increased production. As of June 2014, total gain was 1,344 tonnes. The effects of microbial treatments lasted more than 10 months.

Mongolia

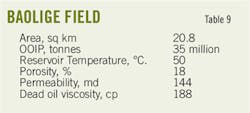

Baolige field, operated by CNPC, covers 20.8 sq km with 78 injectors and 169 producers. Table 8 shows field parameters favorable for MEOR. A large-scale MEOR project started in May 2012. Crews injected nutrients and two strains of bacteria through injection wells. After 60 days, field oil production increased to 920 t/d from 820 t/d. The water-cut dropped to 65.8% from 78.5%.

Oil viscosity fell to 80 cp from 188 cp. The field received four cycles of injection followed by routine water flooding. Around 85% of all production wells reported higher rates after microbial treatments.

Oil production stabilized around 900 t/d until early 2016. An additional 210,000 tonnes of oil was produced.

Nutrients and bacteria also were added to produced water at treatment plants before reinjection into the reservoir.

Pressure increased soon after bacteria injection in most cases. This can be attributed to the plugging of pore throats by microbes, production of biopolymers, or production of gases.

Injection pressure also began to decline at a certain stage. This is possibly because the surfactants produced by bacteria reduced interfacial tension between oil and water, which was also observed at surface.

Viscosity of produced oil decreased for many projects. After microbial treatments, many wells’ paraffin levels also eased.

MEOR, however, involves more uncertainties than steam flood or polymer flood.

Most previous MEOR field cases involved reservoir temperatures below 60° C. because most bacteria cannot prosper at high temperatures. High salinity in deep oil and gas reservoirs also hinders bacterial growth.

Commercial MEOR projects in Daqing and Balige fields involved mild reservoir temperatures and moderate salinity.

MEOR has been tried in fields with high temperature, high salinity, low permeability, and heavy oil. For some field cases, reservoir temperature reached 93º C., salinity as high as 142,600 ppm, oil viscosity as high as 43,000 cp at surface, and reservoir permeability as low as 25 md. Nevertheless, MEOR improved oil production and the projects proved profitable.

According to the field experiences, MEOR application can be extended with proper selection of bacteria and project execution.

Selected strains must be able to prosper under the reservoir conditions. Then they mobilize oil by producing biosurfactants or degrading crude oil. This step requires identification, incubation, and evaluation of strains in laboratory.

The injected slug is intended to build a colony in the reservoir. When only nutrients are injected, the nutrients volume needs to support the long-term metabolism of bacteria. For trials having low success rates, injected slugs were usually much less than 0.05 PV. China field experiences showed the slug size needed to be at least 0.05 PV to achieve high success rates.

Bibliography

Ariadji, T., Astuti, D., and Aditiawati, P., “Microbial huff-and-puff project at Mangunjaya field,” Society of Petroleum Engineers Asia Pacific Oil & Gas Conference, Jakarta, Oct. 17-19, 2017.

Cao, G., Xu, D., and Zhang, S., “Stimulation of internal bacteria at Zhan 3 block,” Journal of Oil and Gas Technology, July 2012, Vol. 34, No. 7, pp. 136-140.

Geetha, S., Banat, I., and Joshi, S., “Biosurfactants: Production and potential applications in microbial enhanced oil recovery (MEOR),” Biocatalysts and Agricultural Biotechnology, April 2018, Vol. 14, No. 4, pp. 23-32.

Ke, C., Lu, G., Li, Y., Sun, W., Zhang, Q., and Zhang, X., “A pilot study on large-scale microbial enhanced oil recovery (MEOR) in Baolige Oilfield,” International Biodeterioration & Biodegradation, February 2018, Vol. 127, No. 2, pp. 247-253.

Le, J., Wu, X., Wang, R., Zhang, J., Bai, L., and Hou, Z., “Progress in pilot testing of microbial enhanced oil recovery in the Daqing field of North China,” International Biodeterioration & Biodegradation, January 2015, Vol. 97, No. 1, pp. 188-194.

Safdel M., Anbaz M., Daryasafar A., and Jamialahmadi, M., “Microbial enhanced oil recovery, a critical review on worldwide implemented field trials in different countries,” Renewable and Sustainable Energy Reviews, March 2017, Vol. 74, No. 3, pp. 159-172.

Wang X., “Application of MEOR in producing ultra-heavy oil from thin pay zones,” Petroleum and Petrochemical Today, May 2016, Vol. 24, No. 5, pp. 20-25.

Wang, X., Xiang, L., and Zhang, Y., “Application of microbial high pour-point oil recovery in Liaohe field,” Lithologic Reservoirs, May 2017, Vol. 29, No. 5, pp. 162-168.

The author

Chang Hong Gao ([email protected]) is associate professor of petroleum engineering at American University of Ras Al Khaimah. Previously, he taught at UAE University, Petroleum Institute Abu Dhabi, and the University of Aberdeen. He also worked for Sinopec as a field engineer and research engineer. He studies oil recovery, drilling fluid, and production technology. He has written two books and more than 20 papers. He received a BS (1999) in petroleum engineering from University of Petroleum (East China), an MS (2003) in petroleum engineering from the University of Tulsa, and a PhD (2008) in petroleum engineering from Curtin University.