EPA speeds regs for offshore synthetic-based mud

The Environmental Protection Agency (EPA), in unusual cooperation with industry work groups, has chosen a streamlined approach to resolve synthetic-based mud (SBM) discharge regulations for offshore operations.

EPA recognizes that current regulations and permits inadequately address SBM discharge issues, instead agreeing to modify the offshore and coastal effluent limitation guidelines (ELGs). An SBM is a drilling fluid believed to be environmentally friendly.

Drilling fluids

Drilling oil and gas wells generates two types of drilling wastes-drilling fluids and drill cuttings. The term "drilling fluids" or "drilling muds" applies to fluids used to help maintain well control, condition the well bore, cool the drill bit, and remove the drill cuttings.

Historically, the oil and gas industry has used water and oil-based muds (WBM, OBM) in offshore drilling operations. WBMs, the least expensive and most widely used drilling fluid, may be discharged to sea, along with associated cuttings, provided that EPA discharge limitations are met.

In some situations, however, difficult drilling conditions with reactive shales, deep wells, and horizontal and extended-reach wells may force operators to switch from a WBM to an OBM. In this case, neither the OBM, which contains diesel and mineral oil, nor associated drill cuttings may be discharged.

Consequently, the agency prohibits any discharge of OBMs and associated cuttings. Instead, the operator must process the OBM for reuse and either inject associated cuttings in a disposal well or haul it ashore for disposal.

SBM qualities

SBMs, which have been developed to replace OBMs, use synthetic organic chemicals as base fluids. In general, they contain no polynuclear aromatic hydrocarbons, exhibit lower toxicity and bio-accumulation potential, and biodegrade faster than OBMs.

Base fluids include linear alpha olefins (LAOs), poly alpha olefins (PAOs), internal olefins (IOs), fatty acid esters, and other formulations.

Therefore, SBM cuttings are less likely than OBM cuttings to affect the seafloor adversely. And although SBMs cost more than OBMs, the nature of SBM-based drilling fluids may permit associated cuttings to be discharged on site.

SBMs also drill a cleaner hole than WBMs, with less sloughing, while generating a lower volume of drill cuttings. Additionally, operators can recycle SBMs while WBMs are typically discharged at sea.

The industry has been eager to use SBMs, particularly in the Gulf of Mexico, where drilling has moved into deep water. Current federal regulatory requirements, however, which predate the common use of SBMs in the offshore industry, do not adequately address the discharge issue of SBM-based cuttings.

Thus, like OBMs, some SBMs continue to be hauled ashore for processing and reuse after the well is drilled.

Federal requirements

Two tiers of federal regulatory requirements, regarding ELGs and permits, govern the discharge of drilling fluids and drill cuttings.

The offshore ELGs (58 FR 12454; Mar. 4, 1993) specify that facilities up to 3 miles from shore, except those in Alaska, may not discharge drilling fluids and drill cuttings. Facilities located more than 3 miles from shore and all Alaskan facilities may discharge drilling fluids and drill cuttings but must meet the following restrictions:

- No discharge of free oil or diesel oil is allowed. This effectively prohibits the discharge of oil-based fluids and cuttings.

- The 96-hr LC50 (50% lethal concentration) test, a concentration at which one half of the test organisms die during a 96-hr toxicity bioassay test, must use at least 30,000 ppm of the suspended particulate phase (base drilling fluid) using mysid shrimp as the test organism.

- Barite, a weighting material in drilling fluids, must not contain more than 1 mg/kg mercury and 3 mg/kg cadmium.

The coastal ELGs (61 FR 66086; Dec. 16, 1996) do not allow discharge of drilling fluids and drill cuttings, except for facilities in Cook Inlet, Alas., which are subject to the same standards used for offshore wells.

The Clean Water Act requires that all wastewater discharges be authorized through a National Pollutant Discharge Elimination System (Npdes) permit. Several EPA regional offices, including Regions 4, 6, 9, and 10, have developed general Npdes permits that cover offshore or coastal oil and gas discharges.

These general permits cover numerous oil-and-gas facilities. Permit limits must be as strict as the national ELGs and may impose additional restrictions, such as discharge prohibitions for drilling fluids made up as inverse emulsions.

The most recent general Npdes permit for the Outer Continental Shelf, issued by EPA Region 6 (Nov. 2, 1998; 63 FR 58722), recognizes that SBMs are distinct from OBMs, although it lacks specific permit language authorizing or prohibiting SBM-cutting discharge.

Efforts

To summarize the advantages offered by SBMs and identify the regulatory barriers that impede widespread use of this innovative and pollution-preventing technology, the U.S. Department of Energy (DOE) in 1995 provided funding to Argonne National Laboratory.1

Following the release of the Argonne report, DOE established an informal synthetic-fluids discussion group. The group included representatives from EPA, DOE, U.S. Minerals Management Service (MMS), and several drilling service and oil and gas companies.

The discussion group provided information to EPA concerning the advantages of SBMs, intending to overcome difficulties experienced by the operators in gaining SBM discharge approval.

Historically, an adversarial relationship has existed between EPA and the industry groups. Thus, early on, the discussion group had to overcome such negative relationships, instead working to build trust between each stakeholder.

The agency used the discussion group to acquire all necessary information for regulatory purposes, motivated by the need to control the waste stream while promoting pollution-prevention technologies.

Initially, EPA planned to develop detailed guidance and language that could be used by EPA regional permit writers to address SBM and cuttings discharge permits. Then during the agency's December 1996 coastal ELG rule-making activities, the agency added several pages of discussion concerning SBMs.

Although falling short of authorizing SBM and associated cuttings discharge issues, the agency kept the door open for further consideration.

Distinguishing definitions

As part of the coastal ELGs, the agency amended definitions for offshore and coastal drilling fluid subcategories. Furthermore, it provided distinguishing definitions among SBMs, WBMs, and OBMs while noting that coastal ELGs do not always apply to SBM discharges.

For example, the discussion groups showed that the static sheen test, used to check for crude oil contamination in WBM discharges, does not apply to SBM testing because synthetic fluids can dissolve crude oil and carry it to the sea floor without creating a sheen.

Additionally, they showed that the toxicity test used for WBMs does not apply to SBM testing because it uses the suspended-particulate phase of a sample, whereas SBMs are found in the sediment phase.

EPA also recommended that gas chromatography be used as a confirmation tool, ensuring the absence of crude oil contamination. In addition, as a helpful tool in controlling the discharge of SBM-contaminated cuttings, the agency recommended that benthic toxicity tests be conducted on synthetic materials before discharge.

Finally, the agency stated its intentions to evaluate bio-accumulation and biodegradation tests as indicators of the rate of recovery for seafloor cuttings piles.

Expedited rule making

Each year, EPA must identify several industrial categories for the development of new ELGs or consider areas where existing ELGs should be revised. In late 1997, the agency announced it would modify the offshore ELGs to include requirements for SBM discharges and cuttings.

Normally, development of an ELG is slow and lengthy. First, the agency must collect extensive data, and with limited external discussions and advice, prepare a proposed regulation. All external parties are given several months to review the proposed ELGs, provide supporting documents, and offer comments.

The agency then takes those comments into consideration when developing the final regulation. The process often takes 4-6 years. Fortunately, EPA recognized the oil and gas industry's need to resolve the SBM discharge issue more quickly.

The agency also recognized the environmental benefits of wider use of SBMs. For these reasons, the agency decided to take a fast-track approach known as "expedited rulemaking," leading to a final regulation in less than 3 years.

Within 14 months, EPA has already published its proposed regulations (Feb. 3, 1999; 64 FR 5487). And because the agency intends to gather additional information in support of the final rule, its plans to publish a supplemental notice for public comment by February 2000. The final rule is scheduled for December 2000.

A new process

To meet this schedule, EPA modified its standard ELG development procedures, under which it collects information without significant review and input from external sources. Under the expedited rulemaking process, the agency relies on industry to supply data in an iterative manner while maintaining some level of communication with external parties throughout the process.

Periodically, EPA, along with industry and other stakeholders, will lay favored options on the table and see how far apart they are. The Synthetic Fluids Discussion Group, restructured to form a steering group including representatives from EPA, DOE, MMS, industry, and a nongovernmental organization, will serve in this capacity.

As follows, industry representatives established five technical work groups to respond to the agency's needs for technical information, shedding light on the progress made through July 1999:

- Analytical work group

- Retention on cuttings work group

- Toxicity work group

- Seabed effects work group

- Biodegradation work group.

Analytical work group

The Analytical Work Group identifies those methods used for determining the presence of crude oil or other petroleum oils in samples of SBM. Ideal methods must be quick, inexpensive, and accurate. Additionally, the group tries to find ways to estimate the detection frequency levels under varying concentrations of crude oil contamination.

Although the static sheen test is the standard and most reliable test for WBM, the group found this method unreliable for SBM testing purposes. For example, test procedures for the majority of WBM samples satisfactorily detected 1% crude oil levels on a volume-to-volume basis yet failed to detect the presence of crude oil in SBM samples even at a 20% level.2

The work group investigated 13 candidate replacement analytical methods, presenting these to EPA in spring 1998. From these alternatives, the agency selected the reverse-phase extraction (RPE) method for offshore use, combined with baseline gas chromatography and mass spectrometry (GCMS) analysis to be conducted onshore.

The GCMS method could also, at the permittee's option, be used to verify any noncompliant RPE test results. In the RPE method, operators extract samples of SBM through small, reverse-phase, filter cartridges, which are then examined under ultraviolet lighting. A fluorescent glow indicates crude oil contamination.

This inexpensive method can be performed quickly in the field, providing a pass or fail result. In addition, RPE sensitivity can be adjusted by altering the extract dilution ratios and amount of extract filtered through the reverse phase cartridge.

Currently, the work group has begun a long-term program to validate the RPE and GCMS methods and to determine the frequency of SBM samples that contain measurable crude contamination.

Cuttings work group

To be used as potential compliance measures, the Retention on Cuttings Work Group studies those methods that can be used to monitor the percentage of SBM retained on cuttings and the quantity of SBM discharged. Additionally, this group applies economic and performance measures for the various solids-separation devices.

Although operators attempt to recycle all of the SBM, cuttings still retain some portion of this fluid in the particle structure.

In 1997, the work group examined SBM mud-recovery devices used in the Gulf of Mexico.3 The study showed that on average 12% of the SBM drilling fluid remains within the cuttings after being processed through the primary and secondary shale shakers, ranging from 4 to 25%.

EPA subsequently performed a statistical analysis of these data, showing that the long term inter-well retention rate of base fluid on cuttings, weighted by hole volume, averaged 10.6% for the primary shale shakers and 15.0% for the secondary shale shakers.

In summer 1998, the work group developed two independent methods--retort and mass balance--to determine the amount of SBM discharged.4 The retort procedure measures the amount of water and base fluid in samples of both SBM and drill cuttings.

From these retort measurements, combined with the mass of cuttings estimated from hole volume, the quantity of SBM discharged can be calculated. This result was then compared with the mass balance method, which tallied all inputs and outputs into the active mud system to provide a highly accurate measurement of the amount of SBM lost.

The drawback to the mass balance method is that the volume of SBM lost downhole must be estimated and added to the amount assumed to be discharged with the cuttings. In the fall of 1998, the work group began collecting data from those wells being drilled with SBMs.

EPA plans to use these data to aid in method selection for the final SBM regulations--either retort or mass balance. These data may also be used to develop relationships between the retention of base cuttings and to develop a relationship between the mass or volume of SBMs discharged per volume or length of the well segment drilled with SBMs. This relationship may be incorporated into the ELGs.

In February 1998, for example, an offshore U.S. trial run for a MUD-10 (Mud Recovery Systems Ltd.) centrifugal solids separator recorded low levels of fines in the SBM, allowing direct release back into the active mud system (Fig. 1).

This work group also plans to collect and verify cost and performance information from vendors of other types of solids control equipment.

Toxicity work group

The Toxicity Work Group strives to identify toxicity bioassay procedures that can measure SBM toxicity and discharge levels. Leading candidates include sediment toxicity tests that typically run for 10 days or longer.

Because SBM tests take 6 days longer than WBM tests, sediment tests become more costly and less convenient as a compliance measure, especially because offshore operators do not have adequate space to store muds and cuttings for the required period of time.

When tests use the bioassay procedure specified for WBMs, most SBMs demonstrate very low toxicity. To some extent, this result is attributable to the inability of SBM to disperse in water, as compared to WBM.

WBMs tend to concentrate in the suspended particulate phase of the sample, while SBMs concentrate in a sediment phase. If operators run bioassay tests on the suspended particulate phase of an SBM sample, the test organisms will not be exposed to the contaminants in the SBM.

After evaluating a variety of potential test methods, the work group hired a contractor to test six types of SBMs using four types of toxicity tests. As of July 1999, the first test rounds indicated no clear-cut best performer. The work group plans to continue testing.

EPA also intends to conduct independent research on the sediment toxicity of the base fluids and on the effect of drilling fluid composition such as barite content, emulsifier package, aqueous phase composition, and crude oil contamination.

For a drilling mud composed of a particular base fluid, if crude contamination affects toxicity levels more than formulation composition, then crude-oil contamination can be used as a pollutant indicator for sediment toxicity at the point of discharge.

Thus, it may be unnecessary to perform sediment toxicity tests at the point of discharge and toxicity levels may be controlled through the base fluid and controls on crude oil contamination. EPA will probably use a 10-day sediment toxicity test with natural sediments in this case.

Seabed effects; biodegradation

The literature contains information about the effects of WBM and OBM fluid and cuttings discharges on the water column and the seabed. Generally, WBMs produce short-term, minor impacts on the seabed, while OBM cuttings introduce long-term, more severe impacts.

Neither type of fluid is believed to cause any long-term water column effects. Little information, however, has been published in the literature on the environmental effects of SBM cuttings discharges.

The Seabed Effects Work Group intends to design a multiyear survey to examine the effects of SBM cutting discharges on seabed abundance and diversity at several discharge sites. The results of the survey will be used by the agency in its Environmental Assessment Report that accompanies the ELGs.

For offshore Npdes permits, it can also serve as the basis for the ocean discharge criteria evaluation required by the Clean Water Act Section 403(c) (40 CFR 125, subpart M; CFR = Code of Federal Regulations). The work group prepared a request for proposal for a comprehensive seabed survey in mid-1999 and plans to select a contractor to conduct the survey in the next few weeks.

In August 1997, the agency provided the work group with a week's worth of time on its research vessel. Crews collected SBM samples from around three platforms in the Gulf of Mexico. A preliminary industry report was then sent to the agency in fall 1998.

EPA collected sediment samples during the cruise, agreeing to analyze benthic abundance and diversity data that should be made available during spring 1999.

Additionally, the Biodegradation Work Group is investigating the available types of procedures for estimating biodegradation. The group plans to sponsor two rounds of tests beginning this fall, hoping to recommend a preferred test by fall 2000.

Options under consideration

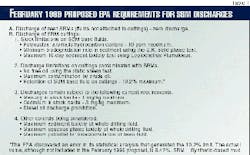

On Feb. 3, 1999, EPA proposed a regulation on SBMs that considered two options: a discharge option and a zero-discharge option.

EPA chose the discharge option for the proposal because it believes that the water quality impacts of appropriately controlled SBM discharges are less harmful to the environment than the non-water quality environmental impacts (fuel use, air emissions, etc.) that would occur if zero discharge had been selected.

EPA also believes the discharge option will encourage further use and development of SBMs as a pollution-prevention technology. The agency points out, however, that the discharge option is feasible only to the extent that discharge controls are adequate and appropriate for SBMs.

The proposed regulations, summarized in Table 1, present control measures the agency thinks adequate and appropriate. EPA believes the proposed limits can be achieved through use of existing treatment technology with the possible addition of a vibratory centrifuge (Fig. 1).

Through the work groups, the agency has worked with industry to address the determination of polynuclear aromatic hydrocarbon content, sediment toxicity, biodegradation, SBM discharge quantity, and the contamination of fluids and cuttings by formation oil. The successful completion of these efforts will be necessary for EPA to continue to reject the zero-discharge option.

Although EPA has proposed these limitations, many of the test methods used to demonstrate attainment with the limitations are still being developed. Additionally, further data need to be gathered to validate the methods and assessment of appropriate limitations for the parameters.

EPA, for example, would prefer to control sediment toxicity at the point of discharge instead of controlling the base fluid. Control at the point of discharge, however, requires further development.

In addition to identifying the candidate requirements, a main purpose of the proposal was to request comments and additional data towards the selection of parameters, methods, and limitations development.

Acknowledgments

John A. Veil's contribution to this article was funded by U.S. DOE's Office of Fossil Energy, under Contract W-31-109-Eng-38. He wishes to thank Robert C. Ayers Jr. for his help in reviewing the article.

References

- Burke, C.J., and Veil, J.A., "Potential environmental benefits from regulatory consideration of synthetic drilling muds," ANL/EAD/TM-43, Argonne National Laboratory, Argonne, Ill., February 1995.

- Weintritt Consulting Services, "Bench scale evaluation of static sheen test for water-based muds, synthetic-based muds, and enhanced mineral oil-based muds," draft, Aug. 28, 1997.

- Annis, M.R., "Retention of synthetic-based drilling material on cuttings discharged to the Gulf of Mexico," prepared for the American Petroleum Institute, Aug. 29, 1997.

- Annis, M.R., "Procedures for sampling and testing cuttings discharged while drilling with synthetic-based muds," prepared for the American Petroleum Institute, draft, Aug. 19, 1998.

The Authors

John A. Veil is manager of the water policy program for Argonne National Laboratory, Washington, D.C. He analyzes a variety of water and waste issues affecting the oil and gas industry for the U.S. Department of Energy.

Veil has a BA in earth and planetary science from Johns Hopkins University, Baltimore, and two MS degrees, zoology and in civil engineering, from the University of Maryland.

Joseph Daly has worked on industrial discharge regulations with EPA for more than 4 years. For the past 2 years, he has worked to develop effluent guidelines that address the discharge of synthetic-based drilling fluids.

Before joining EPA, Daly worked for W.R. Grace & Co. for 5 years, responsible for development of new fireproofing, high-strength concrete and polymer concrete products. He also taught math and science for 2 years as a Peace Corps volunteer in Nepal. Daly received a BS in chemical engineering from Villanova University, and an MS in chemical engineering from the University of Massachusetts.

Nancy Johnson is the director of planning and environmental analysis in the Office of Fossil Energy at the U.S. Department of Energy. She has more than 20 years' experience working on regulatory and policy issues related to energy technologies, most recently focusing on oil and gas. She holds a masters in business from American University, Washington, and a BS in environmental sciences from Windham College, formerly located in Vermont.