NPC details petrochemical projects eyed under Iran's expansion plan

Iran is hoping to entice foreign investors into participating in a major expansion of its petrochemical sector.

The growth plans of Iran's National Petrochemical Co. are ambitious, to say the least. If NPC accomplishes its goals under the multi-phase development program, Iran's capacity to manufacture petrochemical intermediates and final products will grow from 13 million metric tons/year in 1998 to 20 million tons/year in 2001 and 31 million tons/year in 2005.

The program is divided into five phases. Phases 1 and 2 comprise 10 projects due for completion by 2002. These units have a total capacity of 1.8 million tons/year of intermediates and 4.7 million tons/year of final products. Their products will include olefins, polyolefins, aromatics, methanol, methyl tertiary butyl ether, linear alkyl benzene, epoxy resins, and other polymers.

The five units that make up Phase 3 of NPC's development program will have capacity to produce 4.3 million tons/year of intermediates and 6.7 tons/year of final products. These plants will manufacture olefins, polyolefins, methanol, aromatics, and glycols, among other products. The Phase-3 units are tentatively slated for start-up in 2001-05.

NPC has outlined Phases 4 and 5 of its expansion program, which encompass the periods 2005-09 and 2009-13, respectively. These phases will increase NPC's final products capacity by a combined 5.4 million tons/year.

Petrochemicals are a natural extension of Iran's petroleum industry, given the country's vast natural gas resources. Iran has an estimated 24 trillion cu m of recoverable gas, according to Masoud Izadi, head of the country's cost estimation and resource planning department.

But Iran lags behind other key Middle Eastern oil producers-Saudi Arabia, in particular-in terms of total petrochemicals production and the breadth of its product slate.

Historically, Iran has relied largely on oil exports for revenues. Oil sales account for a reported 85% of the country's income. But the oil price crash of 1998 and early 1999 has placed new importance on diversification of Iran's revenue sources.

"Getting away from oil receipts is the best way to improve the economic structure and move into a stage of transferring to non-oil exports," First Vice-President Hassan Habibi told the Iranian News Agency recently. And moving more to exports based largely on products that are a step down the value chain from that vast gas resource-namely the petrochemical sector-is the obvious place to begin.

Petrochemical exports

NPC has markedly increased its export quantities this decade. In fiscal year 1997-98, its petrochemical exports were nine times-based on tonnage-what they were in 1990-91. Over the same period, the value of NPC's annual petrochemical exports grew by a factor of 16.

And Iran's chemical export growth is showing no signs of slowing. NPC now exports about half of its output of final petrochemical products. In 1998, its exports totaled 3.62 million tons, bringing in revenues of $452 million. This was a 16% increase in volume over the previous year and a 10% increase in revenues.

Last year, the composition of NPC's exports was: hydrocarbons, 47% (on the basis of tonnage); basic chemicals, 45%; polymers, 5%; and fertilizers, 3%.

Iran's key petrochemical export markets are: Europe, 24% (on the basis of tonnage); the Far East (excluding China), 24%; India, 19%; China, 12%; and Southeast Asia, 9%.

Continued growth in petrochemical exports is the cornerstone in the development plans of both NPC and the Iranian government.

The incentives offered under NPC's expansion program encourage private-sector investors to export a significant proportion of their petrochemical production (OGJ, Aug. 16, 1999, p. 20). And the government hopes to use petrochemical exports to increase its hard currency revenues and bring its budget closer to balance.

Mohsen Nourbakhsh, governor general of Bank Markazi Jomhouri Islami Iran (Iran's central bank), said, "These petrochemical projects would help tremendously with economic growth and budget balancing."

Expansion Phases 1, 2

NPC has performed detailed studies of the projects that comprise Phases 1 and 2 of its development plan. The scope of this article is limited to these 10 projects.

These units are in various stages of planning, design, and construction. NPC is the sole interest holder in all of the projects, but other state firms have been set up to manage their execution. NPC will consider investment offers for any of the projects.

Most of the complexes planned by NPC-whether in the current development phases or subsequent ones-will be built in one of two special economic zones set up by the country. Operating in these zones affords investors special allowances with regard to taxes and import-export duties.

In addition to the projects NPC has proposed for construction in these zones, private companies are encouraged to propose their own projects for the areas, says NPC.

Of the 10 plants NPC plans to add under the first two phases of its expansion, 8 will be built in the Bandar Imam special petrochemical economic zone on the Persian Gulf coast (see Fig. 1). One of these-a world-scale olefins project described in detail in a previous article (OGJ, Aug. 16, 1999, p. 61)-will be excluded from this discussion.

The remaining two projects comprising Phases 1 and 2 are a methanol plant at Kharg Island, about 190 km southeast of Bandar Imam in the Persian Gulf, and a linear alkyl benzene unit at Bandar Abbas on the northern coast of the Strait of Hormuz.

Aromatics plants

Phases 1 and 2 of NPC's expansion program include the installation of two new aromatics units. One of these, a 180,000 ton/year paraxylene unit under construction at NPC's Bandar Imam petrochemical complex, is slated for start-up by yearend.

NPC currently operates Iran's Nos. 1 and 2 aromatics complexes. Its No. 3 aromatics complex, to be built on a 28-hectare site in the Bandar Imam special petrochemical economic zone, will convert naphtha and pyrolysis gasoline to 430,000 tons/year of paraxylene, 180,000 tons/year of benzene, and various other products.

The paraxylene unit NPC is constructing on a 5-hectare space at the Bandar Imam petrochemical complex will process mixed xylenes feed from the Bandar Imam complex. This project involves a simple mixed-feed fractionation step followed by selective adsorption of paraxylene. The meta and orthoxylene cut is then isomerized, and additional paraxylene is recovered.

Output from this plant will also be used in Iran's first purified terephthalic acid-polyethylene terephthalate (PTA-PET) project. IFP is the process licenser. Belgium's ABAY Engineering SA and Iran's Chemi-Naft Co. are performing basic and detailed engineering and procurement. And Tehran-based Technicon is responsible for construction and commissioning.

The projected capital cost of the complex is $82.2 million. Project execution is being managed by Petrochemical Industries Development Management Co. (Pidmco).

NPC's proposed No. 3 aromatics complex consists of these key processing steps: naphtha prefractionation, naphtha hydrotreating, catalytic reforming, pyrolysis gasoline hydrogenation, benzene-toluene-xylene (BTX) extraction, aromatics fractionation, toluene and C9+ aromatics transalkylation, paraxylene separation, and xylene isomerization.

NPC has signed process licensing and basic engineering contracts with France's Institut Français du Pétrole (IFP) and Germany's Krupp Uhde GmbH. Detailed engineering, procurement, and construction contracts have not been let.

Total capital cost for the complex will be $357 million, says NPC. This assumes, as is the case with all the capital costs quoted in this article, that Iranian sources supply 64% of the engineering services, 30% of the equipment and materials, and 100% of construction services.

Feeds to the aromatics complex will be light and heavy naphtha streams from the Pazanan gas processing complex and pyrolysis gasoline from the sixth and seventh olefins projects. Paraxylene output will be used to manufacture terephthalic acid for production of polyester resins and fibers in NPC's first and second PTA-PET plants. Benzene production will be used in the manufacture of: ethyl benzene for styrene monomer production, dodecylbenzene for detergents manufacturing, cyclohexane for nylon production, phenol, nitrobenzene, maleic anhydride, and various other products.

LPG output will be consumed domestically as fuel and used as feedstock for olefins production. A raffinate stream, light ends, and a C5 cut will also be used to produce olefins. And a heavy aromatics stream and heavy ends will be returned to National Iranian Oil Co. for use in fuels blending.

Feedstock inflow and product outflow rates are shown in the flow diagram (Fig. 2).

The aromatics complex is slated for start-up in March 2001. Bou-Ali Petrochemical Co. is responsible for overall project execution.

PTA-PET complexes

Two PTA-PET complexes are included in NPC's first and second expansion phases. The first plant, slated for completion in March 2001, will have capacity to produce 352,000 tons/year of fiber-grade PET and 60,000 tons/year of bottle-grade PET. The second complex, also scheduled for start-up in 2001, will have capacity to produce 235,000 tons/year of fiber-grade PET and 177,000 tons/year of bottle-grade PET.

Both plants will be built in the Bandar Imam special zone. Eachc has an estimated capital cost of $606.5 million.

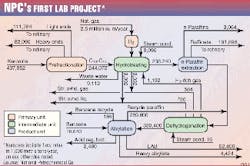

The process for production of PET involves oxidation of paraxylene to produce terephthalic acid, which is then purified via hydrogenation to produce PTA.

Bottle-grade PET is then produced from the PTA in four stages: two esterification steps followed by prepolycondensation and polycondensation. To produce fiber-grade PET, a single esterification step is followed by two prepolycondensation steps and two polycondensation steps (Fig. 3).

The first PTA-PET complex will use the PTA technology of Italy's Tecnimont SpA and the PET technology of Germany's Zimmer AG. Those contractors will also perform basic engineering on the respective units. Detailed engineering and procurement will be done by: Iran's Sazeh Consulting Engineering Co. and South Korea's Daelim Engineers & Constructors for the PTA unit; and Zimmer and Iran's Chegalesh Consulting Engineers for the PET unit. Overall project execution is being managed by Shahid Tondgooyan Petrochemical Co.

No information is available on the contractors and licensers for the second PTA-PET complex, but this project will be overseen by Mobin Petrochemical Co.

Sixty-eight percent of the output of the first complex and 73% of the production from the second complex will be exported.

Methanol plants

NPC has two methanol plants planned during its first and second development phases.

One is being built on a 15-hectare site on Kharg Island, next to NPC's Kharg petrochemical complex. This unit is past due for start-up and is expected to be commissioned shortly.

This 660,000 ton/year plant will convert lean gas (a mixture of methane and ethane) from the Kharg complex into methanol, most of which will be converted to MTBE. The availability of the Kharg feedstock was the deciding factor in the location of this unit, says NPC.

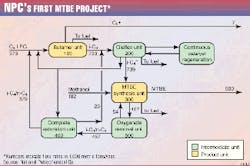

The plant will employ steam reforming to produce the synthesis gas that is needed for methanol synthesis (Fig. 4).

Germany's Lurgi AG provided the process license and performed basic engineering for the plant. Shiraz-based Petrochemical Industry Design & Engineering Co. (Pidec) performed detailed engineering and procurement. And Erection & Construction Co., also of Shiraz, is the construction contractor. Pidmco is handling overall project management.

Total capital cost of the plant is about $297 million. NPC expects about 28% of the output to be used domestically.

NPC's third methanol project-designed to produce 1 million tons/ year-will be built on 20 hectares in the Bandar Imam special zone. It will process natural gas from the Bid Boland gas processing plant using the same conversion scheme as the second methanol plant.

Like the other unit, its output will be used primarily to produce MTBE.

The project is being executed by Fanavaran Petrochemical Co., which has not chosen process licensers or engineering-procurement-construction contractors. Start-up of this unit is slated for March 2002. Total capital cost is an estimated $431 million.

MTBE unit

Also planned by NPC is a 500,000 ton/year MTBE unit, to be built on 10 hectares at the Bandar Imam complex. The unit's two main feedstocks will be methanol from the Kharg Island plant and butanes from the Bandar Imam complex.

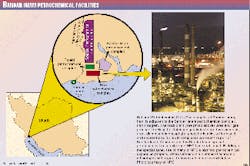

The MTBE production process involves separating isobutane from a mixed-C4 stream, converting recovered normal butane to isobutane, then dehydrogenating the isobutane to produce isobutylene. This product is fed, together with the methanol, to the etherification unit for MTBE synthesis (Fig. 5).

Pidec is performing basic and detailed engineering and procurement on this project, and Pidmco is responsible for overall project management. Start-up is slated for early 2000.

Total capital requirements for the project are $277.7 million. Iran will use 40% of the MTBE domestically to boost gasoline octane, thus facilitating the removal of tetraethyl lead from Iran's gasoline pool. (Iran spends $50 million/year to import TEL for gasoline blending.)

Linear alkyl benzene

Iran's first linear alkyl benzene (LAB) unit will be built on an 8-hectare plot at Bandar Abbas. This unit's main feedstocks will be kerosine and hydrogen from the Bandar Abbas refinery and benzene from the Bandar Imam petrochemical complex.

Contracts for process licensing, engineering, procurement, and construction have not been let. Project execution is being managed by Mashaldaran Petrochemical Co.

NPC has not yet specified a start-up date for this plant.

To produce LAB, kerosine feed will be fractionated to obtain a heart cut (the light and heavy ends will be returned to the nearby refinery). The heart cut will be hydrotreated to remove contaminants, then n-paraffins will be separated from the stream (Fig. 6). The olefins will be recycled to the hydrogenation unit, and the n-paraffins will be processed, along with benzene feed, in an HF alkylation unit.

The LAB unit will have a production capacity of 50,000 tons/year and an estimated capital cost of $92 million. All of the LAB output will be exported for use in liquid and powder detergents, while the heavy alkylate will be used domestically to produce textiles, industrial lubricants, and lubricant additives.

Engineering polymers plant

NPC is also planning to build an engineering polymers and fine chemicals complex on an 8-hectare site in the Bandar Imam special zone. This plant is scheduled to start up in October 2001.

Salzgitter AG will provide technology licensing and basic engineering for the complex. Detailed engineering, procurement, and construction contracts have not been let. The project will be managed by Khuzestan Petrochemical Co.

Feeds to the complex will include natural gas, acetone, phenol, epichlorohydrin, chlorine, and toluene. Most of the feeds will come from the Bandar Imam petrochemical complex, but the natural gas will come from the main pipeline in the area.

This project consists of seven processing steps: synthesis gas production, CO separation, phosgene synthesis, bisphenol-A production, carbonate polymerization, liquid epoxy resin production, and solid epoxy resin production.

Natural gas is reformed to produce synthesis gas, the CO component of which is reacted with chlorine to produce phosgene. Acetone, phenol, and toluene are reacted to produce bisphenol-A. Then a portion of the bisphenol-A is processed via phosgenation and polycondensation to produce polycarbonate.

The remaining bisphenol-A is reacted with epichlorohydrin to form BPA dehydrochlorine ether, which is dehydrochlorinated to produce diglycidyl ether of bisphenol-A (Dgeba), or liquid epoxy resin. A portion of the Dgeba is reacted with additional bisphenol-A and polymerized to produce the solid epoxy resin.

Production capacities of the complex will be: 25,000 tons/year of polycarbonates, 6,000 tons/year of liquid epoxy resins, and 4,000 tons/year of solid epoxy resins. Seventy-five percent of the polycarbonates output will be exported, as will 83% of liquid epoxy production and 75% of solid epoxy production. Total capital cost of the plant is $169 million.

Utilities, offsites

Operators in the Bandar Imam special petrochemical economic zone will benefit from a utility and service infrastructure project that NPC is implementing. The project will be managed and operated by Fajr Co.

The utilities project will supply:

- River water treatment, 6,900 cu m/hr.

- Cooling water, 140,000 cu m/hr.

- Drinking water, 300 cu m/hr.

- Service water, 450 cu m/hr.

- Fire-fighting water, 3,300 cu m/hr.

- Demineralized water, 660 cu m/hr.

- Steam, 970 tons/hr at 41 bar.

- Electricity, 455 MW.

- Waste water treatment, 3,800 cu m/hr (maximum).

- Instrument air, 14,000 cu m/hr.

- Compressed air, 17,000 cu m/hr.

- Nitrogen and oxygen, 18,000 cu m/hr each.

Feedstocks to the utilities and offsites units will be fuel gas, air, and water from the Karoon, Jarrahi, and Zohreh rivers.

These facilities will be constructed on a 22-hectare site in the 200-hectare southernmost section of the petrochemical zone, called Zone 4. Also to be built in this section are the Nos. 6 and 7 olefins units, the Nos. 1 and 2 PTA-PET units, the No. 3 aromatics complex, and the engineering polymers complex.

The special petrochemical economic zone will contain three other subzones. The 260-hectare Zone 3 is reserved for large petrochemical complexes. The 350-hectare Zone 2 will contain the main office building, hotels, a recreation area, medium-sized industrial facilities, warehouses, and a railway station. The northernmost section-the 240-hectare Zone 1-is reserved for small and medium-sized facilities and related service units.

Clever, but achievable?

NPC's expansion scheme has been well thought out. It makes use of Iran's abundant natural resources to produce a broad slate of value-added petrochemical products. And, if completed as planned, the expansion will go a long way toward diversifying Iran's export revenue sources, thus reducing the economic risk the nation experiences as a result of its dependency on oil export revenues.

Clearly, NPC has also given much consideration to integrating the flow of feedstocks and products between these planned units and Iran's existing petrochemical complexes, refineries, and gas processing plants.

But several questions remain:

- Is demand growth in consuming regions adequate to justify the large capacity increases NPC is planning? The company says that it has taken this issue into account and that the added capacity is justified, based on projected future demand.

- Will foreign investors respond to NPC's overture? Given the available economic incentives and operational advantages, chances are that they will, although the degree of enthusiasm is difficult to predict.

- Will NPC meet its expansion goals, as outlined? Given the ambitious nature of the program, probably not, but the company is expected to achieve marked increases in capacity and a significant broadening of its product slate in the coming 5 years.

- Will the economic and political changes taking place in Iran provide an investment environment with a level of risk that is acceptable to foreign companies? Almost certainly, officials contend. According to Mohammad Ali Najafi, Vice-President of Iran and head of Iran's planning and budget organization, the goals of Iran's third social and economic plan are economic growth of 6%/ year, controlled inflation, and improved wage distribution. "The third plan aims at paving the ground to become the largest economy and industry in the region," he told potential petrochemical investors at NPC's Iran Petrochemical Forum in Tehran last April. "The general trend is a gradual opening of the Iranian economy to foreign competitors, especially in oil and gas production and petrochemicals." Also under the third plan, Iran's banking and insurance industries-as well as other monopolies-will be reformed. And the foreign currency system will be revised to standardize parity rates. "We must revise the laws that monopolize production and distribution of goods, on a timetable," said Najafi. "All these things will provide a framework for liberalization and pave the ground for the economic growth that this plan envisions."

- Will the U.S. government respond to Iran's changes by revoking its unilateral economic sanctions against Iran, thus allowing U.S. companies to take advantage of the enticements Iran is offering? Not in the near term, barring unforeseen events. But there does appear to be movement in that direction, however slow.