Off-design performance evaluations increase hot-gas expander reliability

Ji Zhang, Zhongshi WangOff-design performance evaluations of hot-gas expanders help operators improve the operating reliability of their power-recovery systems and processing plants.

Sinopec

Jinan, China

Although rotating machinery performs efficiently within design conditions, design conditions do not always exist. Off-design conditions occur when operating conditions are different from design conditions.

Analysis of the off-design performance of an FCC hot-gas expanders was performed at the Sinopec Jinan oil refinery (JOR). An analysis based on velocity diagrams and performance curves is necessary and valuable to determine the effect of off-design conditions.

Power trains

In China, the first fluid catalytic cracking (FCC) power train was built at the end of the 1970s. In the past 10 years, the construction of power trains has increased rapidly as a result of increased consumer power demands and government environmental demands. Although most units have been reliable for 10 or more years, power trains have required the majority of the maintenance in China's FCC units.There are good reasons to invest in the maintenance of power trains, which handle catalyst-laden gas at high temperatures. They join with not only the processing plant, but also the steam-piping network and the electrical-power grid. An upset of the train can rapidly extend from the FCC unit to the whole plant.

The hot-gas expander, also called the expander, to be examined is a major part of the power train.

In a power train, the expander drives the axial air blower which, in turn, is connected to an asynchronous motor/generator by a gear box. Sometimes, a start-up steam turbine is also involved (Fig. 1 [61,141 bytes]).

Power trains have different performance characteristics and construction features than conventional machinery. Conventional rotating machines usually consist of a prime mover and an operator, such as a motor and a pump or a turbine and a compressor.

Expander details

Fig. 1 shows a diagram of the power train started up in May 1989 after 2 years of construction. Table 1 [56,352 bytes] lists the specifications for the machines. 1Among them, the expander is a two-stage overhung unit. Its rotor rests on two journal bearings and one tilt pad-type thrust bearing. The cast labyrinth seal is protected by steam on the gas side and purged by pressurized air.

In the bearing casing, there are three sets of Bently monitor probes, two for vibration and one for axial displacement. A blast of steam is introduced to prevent catalyst deposits from forming between the rotor disks and to control the temperature of the disks.

Because much system maintenance is associated with the expander, the life expectancy of an expander often determines the system maintenance and turnaround. Thus, advanced construction materials and deliberate design ensure reliability of the expander as well as the power-recovery system.

The proper choice of metallurgy allows the expander to withstand great heat and erosion.2 3 JOR's rotor disks and rotor blades are made of GH864, an alloy developed by a Chinese manufacturer with properties similar to Waspaloy (a heat-resistant alloy manufactured by Goodfellow Corp.).

The JOR expander uses a reaction of 50%, which gives the best overall efficiency. The reaction is the ratio of the pressure drop of the rotating blades and the overall pressure drop of that stage. The blades reduce gas flow velocity, and thus reduce the kinetic energy of catalyst particles. The aero-foil surface of the blades is carefully designed according to principles of aerodynamics.

Gas flow

Table 2 [48,273 bytes] shows an analysis of the flue gas from the FCC regenerator to the hot-gas expander inlet. Gas concentration, catalyst dust concentration, and particle sizes are examined off-line weekly.Hot flue gas produced from the FCC is expanded in the expander and supplies mechanical energy for processing. The excess power is converted into electrical energy by the generator. Therefore, the power-recovery system can raise the energy efficiency of the plant considerably.

To calculate power output, a couple of assumptions must be made:

- Because the flue gas in the expander has a very high temperature and a low pressure, it can be thought of as an ideal gas.

- Because the exhaust gas pressure and the temperature are nearly unchangeable (unless the efficiency degrades), the expander's residual enthalpy may be considered constant.

Mass flow deviation in FCC systems is common because operations are frequently adjusted to meet petrochemical market demand. During deviations, inlet parameters should be controlled. It is important to keep the volume flow in the normal range to maintain the efficiency of the system. The effects of temperature and pressure on volume can be expressed with the ideal gas law:

p1v1 = RT1

where:

p = Pressure

v = Volume

R = The universal gas constant

T = Temperature.

The higher the gas temperature or the lower the gas pressure, the larger the gas volume which flows through the expander. Hence, higher inlet temperatures and lower inlet pressures are desired when reduced gas mass flow is encountered.

When the mass flowing through the expanders is reduced, power loss occurs. Also, efficiency is reduced by two factors: the increased deflective angle of gas in the leading edge of the rotating blades and the increased pressure drop across the inlet butterfly valve when the valve closes.

As long as the volume of flow is kept near the normal level, both the deflection angle and the pressure drop can be corrected. Because temperature increase is limited by the metallurgy, the volume is controlled by adjusting the inlet pressure. The volume at various pressures can be estimated by:

p1'v1' = p1v1 Even in low mass-flow conditions, power trains can operate economically. Cases are known where gas flow was about 20% less than the rated amount. In those cases, the inlet pressure should also decline by 20%.

In JOR's expander, the corresponding inlet pressure would be about 0.25 MPa. When the inlet pressure was adjusted to 0.22-0.24 MPa, the expander matched the system perfectly, but the power loss was considerable. The power consumption of the air blower was reduced at the same time that the regenerator pressure was reduced. Thus, overall efficiency of the power recovery system was not affected to any considerable degree.

Alternate ways to cope with gas-flow deviation have been proposed: retrofit of the stator-nozzle assembly5 or replacement of rotors with shorter blades. However, it is preferable to correct the volume flow by lowering the inlet pressure because it avoids the possibility that excess catalyst will pass through the mechanical device.

Erosion and plugging

In a hot-gas expander, there are two major problems associated with catalyst fines: blade erosion and dust plugging. To prevent failed turbines, machine manufacturers recommend the maximum permissible dust concentration upstream of an expander be 200 ppm with 97% of the particles less than 10 m in size. Sometimes, 160 ppm with 95% of the particles less than 10 m is allowed in the dust concentration.Off-design condition analysis should anticipate excessive catalyst flows, especially those that occur during process upsets.

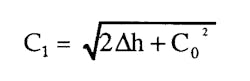

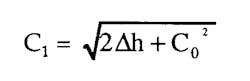

Excessive catalyst flow can be divided into two cases: excessive concentrations of larger particles (10 m or larger) and excessive concentrations of fine dust (10 m or smaller). These cases can occur at one time. Erosion. Erosion is caused by the impact of catalyst particles larger than 10 m. Larger particles possess more kinetic energy, represented by mv2 (mass times the square of velocity), than smaller ones. In the blade's path, particles deflect from the flow line due to inertia. The larger the particles are, the worse the deflection is (Fig. 2 [42,182 bytes]).Inspection during shutdown showed evidence of blade erosion and pits located on the leading edge and on the concave side of the trailing edge (Fig. 3 [43,441 bytes]). Because an expander operates at constant revolution, the velocity diagram depends on the absolute speed of the mass carrier, which in this case is flue gas. The absolute speed of gas at the first stage of rotor blades, C1, may be calculated from the nozzle formula:

In JOR's expander, if the primary velocity is 89 m/sec (rated flow of 30 normal cu m/sec), the absolute speed C1 is about 376 m/sec. Fig. 4a [66,271 bytes] shows the velocity diagram at the inlet of the first stage rotor blades.

Fig. 4b shows the new velocity diagram when the absolute speed C1 is reduced by 50%. As the relative flow angle, b, changes, the collision angle between catalyst particles and blade changes in a way that prolongs the life of the blades.Thus, it is practical to either lower the gas mass flow or lower the gas inlet temperature when an excessive concentration of larger particles is noticed.

Plugging. When excessive concentrations of fine dust occur, catalyst deposits may be detected. Because of the high degree of sophistication of the dust-plugging mechanism, there has been no uniform explanation for this malfunction.

However, one rule has been found based on field experience. The catalyst dust buildup always settles in lower-velocity areas, such as in stator paths, at the trailing edges of rotor blades, and between the rotor disks. The buildup occurs after excessive concentrations of fine dust have passed through the expander.

One expert has proposed rapidly cooling the expander by steam combined with flue gas to leave the expander free of deposits.6 Unfortunately, this corrective measure is unsuitable for multistage expanders because catalyst flakes remain in the space between the disks. Moreover, there is a danger in this cooling process because it could cause localized cooling in the expander and partial deformation of components.7

Prevention is always a good method to keep the machines from dust plugging. A steady blast of overheated steam would prevent catalyst carryover from entering the space between the disks.

Raising the gas temperature, lowering the gas inlet pressure, or doing both would prevent dust plugging. These measures increase the volume flow of the gas and reduce the possibility of catalyst buildup in the expanders.

Key points

Having performed an off-design analysis of one FCC hot-gas expander at Sinopec's Jinan oil refinery, the key points to remember are:References

- Zhang, Ji, et al., "The Operation Analysis of Different Service Condition for Compressor Unit of Energy Recovery," Petrochemical Equipment Technology, Vol. 17, No. 4, 1996, pp. 17-22. (published in Chinese).

- Wang, Di, "The Research and Manufacture of the Heat-resistant Components Utilized in YL Series Expander Turbine," Petrochemical Equipment Technology, Vol. 12, No. 3, 1991, pp. 12-16. (published in Chinese).

- Ye, Ruizeng, et al., "Domestic Flame Coating for Blades of the Gas Expander Turbine," Petrochemical Equipment Technology, Vol. 12, No. 3, 1991, pp. 19-24. (published in Chinese).

- Yahya, S.M., Turbines Compressors and Fans, Tata McGraw-Hill, 1985, p. 28.

- Dziewulski, Tony A., "Tune-up your FCCU expander," Hydrocarbon Processing, August 1994.

- Franzel, H.L., "Maintenance of FCC Power Recovery Systems," Hydrocarbon Processing, January 1985.

- Roy, G.K., "Improve FCCU Expander Reliability," Hydrocarbon Processing, March 1994.

The Authors

Ji Zhang is a mechanical engineer at Sinopec's Jinan oil refinery (JOR), where he has about 14 years of experience with petrochemical processing equipment. Presently, he designs pressure vessels for JOR.From 1988 to 1993, Zhang supervised the construction, start-up, and operation of an FCC power recovery system in JOR. He has authored several papers in Chinese about maintenance, operation, and failure analysis of rotating machinery in refineries. Zhang holds a BS in mechanical engineering from the University of Petroleum in China.

Zhongshi Wang has over 15 years of experience in petrochemical plants. Presently, he serves Sinopec's Jinan oil refinery as a condition-monitoring specialist, maintaining and troubleshooting large rotating equipment. Previously, he worked as a mechanical engineer at Sinopec's Lanzhou Petrochemical Co. for 7 years.Wang has published several articles in Chinese. He holds a BS in mechanical engineering from the University of Petroleum in China.

Copyright 1997 Oil & Gas Journal. All Rights Reserved.