CNOOC advances water control in South China Sea

Ribin Xie

China National Offshore Oil Corp.

Shenzhen Ltd.

Shenzen, China

Haitao Li

Southwest Petroleum University

Chengdu, China

Feng Li

Yong Yang

Xinbo Zou

Xian Tian

Yuanzhi Liu

China National Offshore Oil Corp.

Shenzhen Ltd.

Bailin Pei

Songmei Zhang

Anton Bailin Oilfield Technology Co. Ltd.

Beijing

A continuous pack-off inflow control device (CP + ICD) completion in the South China Sea produced tenfold the oil in 3 months as three adjacent wells within 150-200 m that were completed without CP + ICD.

China National Offshore Oil Corp. (CNOOC) worked with Anton Bailin Oilfield Technology Co. to apply the water-control technique. Well 04, featuring the CP + ICD completion, set a record for initial 3-month production in the Liuhua fractured carbonate reservoir.

Liuhua field is in the southwestern Dongsha uplift in the Pearl River Mouth basin of the South China Sea. The uplift features a bioreef-anticline structure with a reef facies reservoir on the edge of Neogene Mesozoic carbonate rock.

Well 04 is an 845-m lateral drilled 40 m above the water contact. The pay zone is about 8 m thick. Oil saturation is 59-62%, porosity is 20-30%, and permeability is 200-2,000 md.

Many horizontal wells experience early water breakthrough (WBT), yielding higher water-cut rates. Higher water production increases lift and disposal costs while reducing oil production (OGJ, Apr. 2, 2018, p. 56).

Industry widely uses ICD completions in horizontal oil wells across the Middle East and Norwegian Sea.

But industry often cannot identify the WBT point or realize when wellbore conditions deteriorate. These problems can lead to well abandonment and economic loss.

This article outlines how CP + ICD used during drilling can maximize oil recovery in water-driven carbonate reservoirs for a field’s life.

Dual permeability

Carbonate reservoirs feature dual permeability. One permeability is from the matrix: the rock’s pore space filled with very fine sand. Another permeability is from randomly distributed fractures.

Fracture permeability can range from a few to 10 times matrix permeability. In water-driven carbonate reservoirs, fractures act as water conduits, accelerating water-to-oil ratios. Remedies, such as water shutoff and zonal isolation, typically fail in carbonate reservoirs, resulting in poor oil recovery and undesired water production.

Operators increasingly use ICDs to adjust uneven oil flow caused by reservoir heterogeneity. ICDs help reduce pressure along horizontal well sections. Decreased pressure maximizes oil flow by suppressing water flow.

Over a field’s life, many wells produce water due to deteriorating wellbores caused by ineffective cement jobs and water channeling behind tubing. Operators seeking additional isolation often use more cement and also packers.

Water-control issues in fractured carbonate reservoirs include:

• Inability to locate fractures and to forecast which fracture will produce or is producing water.

• Inability to seal WBT points with cement after circulation loss.

• Ineffectiveness of external casing packers, which isolate a limited horizontal interval that produces water in the wellbore but cannot seal reservoir water inflow to unpacked intervals.

• Difficulty in retrieving tubing caused by irregular hole diameters.

CP + ICD advantages

CP + ICD involves two components: the ICD and the particles. ICDs constrain perpendicular-to-the-well flow along horizontal sections, minimizing the water flow into the well bore.

For a horizonal well, the WBT point is a high-inflow interval. CNOOC injected particles into the well annulus to prevent annular water flow.

The synthetic, solid particles are spherical with a density resembling water, easily filling any voids in the annulus. The synthetic particles are nonreactive with the minerals, fluids, and other completion materials.

Industry widely uses cementing, chemical squeezing, and expendable packers although crews must locate WBT points. The advantage of CP + ICD particles is that they are effective without the operator locating WBT points. It also is unnecessary to know whether the water source is the formation or the wellbore.

If the water is from reservoir, CP + ICD can adjust itself to cut down the inflow water rate without knowing:

• Fracture locations (water conduits).

• How many fractures will produce water and how much water.

• WBT timing.

In a faulty well with leaking water production, CP + ICD can adjust to seal cement behind any channeling and water channeling:

• From irregular wellbore diameter.

• In the outer perforated casing.

• In the outer screen.

CP-ICD technology is effective in completing from small to big wellbores because CP + ICD base pipe can be minimized to 1.9 in. OD. CP + ICD retrieval is a standardized operation following these steps: unlocking the hanger, circulating the particles to surface, and pulling the ICD string. Field trials have retrieved all CP + ICD materials, including the synthetic particles, which can then be reused.

Field application

Liuhua field is a natural water-driven fractured carbonate reservoir featuring a complex system of minor faults, fractures, and matrix. The reservoir is known for its direct oil-water contact.

CNOOC developed Liuhua using extended reach wells with drilling trajectories of 3-5 km. The massive aquifer provides enough pressure support, but early WBT hinders oil recovery. The field produced for more than 20 years, with all wells drilled before 2018 having reached water cuts of more than 90%.

Engineers planned infill drilling to improve oil recovery, but massive operational data, including high-resolution 3D seismic, failed to slow water production. During 2004-13, all sidetrack wells (one well each in 2004, 2005, and 2013) reached 90% water cut within 30 days of coming on stream.

Past water-control applications included one chemical treatment (March 2010) followed by two trials using CP + ICD (September 2013 and May 2014). The chemical treatment damaged productivity without reducing the water cut. Researchers reported 30% less oil being produced after the chemical treatment. These wells reached 96-97% water cuts before ICD + oil-swellable packers installation.

These applications, however, were workovers of high water-bearing production wells in late-life production. Two wells received casing perforations with 160-m and 260-m horizontal sections. The third was an open-hole completion with a 640-m horizontal section. Before August 2018, CP + ICD had not been applied to any new wells while drilling.

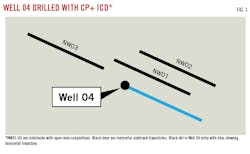

Fig. 1 shows the patterns of Well 04 compared with the three high-water wells with open-hole completions (NW01 in 2004, NW02 completed in 2005, and NW03 completed in 2013).

Fig. 2 shows higher water-cut behavior for the three open-hole completions than for the CP + ICD completion done in 2018, which maximized oil recovery by stabilizing water production.

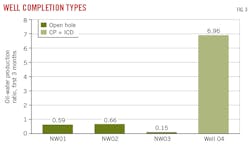

Fig. 3 shows Well 04 outperformed the oil-water ratio from the earlier open-hole completions.

Water-control recommendations

ICD is a mature well completion technology. Many researchers have studied how ICDs maximize oil recovery by controlling water production in various reservoir types and under many wellbore conditions.

Integrated water-control measures for carbonate and highly heterogeneous reservoirs often require annular isolation. Industry has successfully used mechanical packers, chemical treatment, and hybrid technologies involving expandable packers.

However, conventional water-control completions face limitations in carbonate reservoirs such as short-seal distance, reservoir damage, and wellbore reliability issues.

The four Liuhua wells received water control at various times during December 2015 through March 2018. All four were drilled during a late-life field cycle, showing water cuts of 96-99.8%.

Well 04, the first well completed using CP + ICD, demonstrated lower water cuts and longer stabile oil production than did the three open-hole completions to which crews later added CP + ICD.Field practices led CNOOC to make the following conclusions:

• Industry can use synthetic particles to address all WBT sources. Water control is deployable at any stage of production using suitable particles and ICD.

• CP + ICD while drilling can provide water control throughout a field’s life, saving costs and maximizing oil production, especially in water-driven or water-flooded reservoirs.

• Various reservoir types can benefit from CP + ICD completions based on previous research elsewhere (OGJ, May 1, 2017, p. 52). Previous, CP + ICD proved successful in sandstone reservoirs of onshore northwestern China oil fields (OG, Oct. 3, 2016, p. 52).

• CP + ICD technology simplifies the reservoir knowledge required of engineers compared with alternative completion technologies.

Bibliography

Li, Z., Fernandes, P., and Zhu, D., “Understanding the Roles of Inflow-Control Devices in Optimizing Horizontal-Well Performance,” Society of Petroleum Engineers Drilling & Completion, Vol. 26, No. 3, September 2011.

Majhi S., Al-Otaibi B., Al-Omair, S., and Abdullah M., “Mitigating Water Recycling in a Heterogeneous Carbonate Reservoir,” SPE, Kuwait Oil & Gas Show and Conference, Mishref, Kuwait, Oct. 11-14, 2015.

Mgimba, M., “Numerical Study on Autonomous Inflow Control Devices: Their Performance and Effects on the Production from Horizontal Oil Wells with an Underlying Aquifer,” Norwegian University of Science and Technology Department of Petroleum Engineering and Applied Geophysics master’s thesis, August 2018.

Youl, K., Harkomoyo, H., Suhana, W., Regulacion, R., and Jorgensen, T., “Passive Inflow Control Devices and Swellables Packers Prove to Control Water Production in Fractured Carbonate Reservoir: A Comparison with Slotted Liner Completions,” SPE Drilling Conference and Exhibition, Amsterdam, Mar. 1-3, 2011.

The authors

Ribin Xie ([email protected]) is CNOOC Shenzhen general manager of producing assets. He is a PhD candidate with Southwest Petroleum University, Chengdu, China.

Haitao Li ([email protected]) is a professor at Southwest Petroleum University. He holds a PhD and specializes in well completion, water injection, unconventional oil and gas extraction, and water control of horizontal wells.

Feng Li ([email protected]) is an upstream department head of CNOOC Shenzhen. He is pursuing a PhD with State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, Southwest Petroleum University, Chengdu, China.

Yong Yang([email protected]) is a subsurface manager of CNOOC Shenzhen. He specializes in enhanced oil recovery, well completion, and offshore oil and gas extractions.

Xinbo Zou ([email protected]) is a technology institute director of CNOOC Shenzhen. He holds a BS of petroleum engineering from China University of Petroleum.

Xiang Tian ([email protected]) is a CNNOC Shenzhen senior reservoir engineer. He obtained a BS and MS of petroleum engineering from Changjiang University.

Yuanzhi Liu ([email protected]) is a CNNOC Shezhen reservoir engineer with experience in well test, production logging and offshore oil and gas reservoir surveillance.

Bailin Pei ([email protected]) is an associate professor in the petroleum engineering department at China University of Petroleum in Beijing. He holds a BS and MS in petroleum engineering from Southwest Petroleum University and a PhD in hydromechanics from the University of Science and Technology of China, Hefei. His research covers horizontal well water control, sand prevention, and inflow control devices.

Songmei Zhang ([email protected]) is a senior reservoir engineer at Anton Bailin Oilfield Technology specializing in water-control issues and sand prevention. Zhang graduated from China University of Petroleum in Beijing with an MS (2004) in petroleum engineering.