Cairn implements chemical EOR in Rajasthan oil fields

Sanjay Kumar

Amitabh Pandey

Cairn Oil & Gas, Vedanta Ltd.

Gurgaon, India

Cairn Oil & Gas, a unit of Vedanta Ltd., accelerated enhanced oil recovery (EOR) pilots in Mangala, Bhagyam, and Aishwariya fields (MBA), where it plans to implement field-scale chemical EOR.

Fluid and rock characteristics led Cairn to estimate EOR potential at 300-400 million bbl for MBA fields. EOR planning became an integral part of field development strategy for the three fields in the western India desert state of Rajasthan.

Engineers started EOR pilots in Mangala right after the field came on stream. Field-scale polymer flood (PF) is ongoing in Mangala field with plans to implement it in Bhagyam and Aishwariya during 2019.

Stock tank oil initially in place (STOIIP) for the three fields is estimated at more than 2 billion bbl with Mangala alone holding more than 1 billion bbl STOIIP.

Mangala field is one of India’s largest onshore oil fields. The Fatehgarh reservoirs feature multi-Darcy permeability sandstones with very low-connate water saturations and reservoir temperatures of 62° C.

Engineers reported a successful alkaline-surfactant-polymer (ASP) pilot in Mangala with similar pilots planned for Bhagyam and Aishwariya in late 2019. Large-scale ASP implementation is planned in Mangala followed by staged implementation in Bhagyam and Aishwariya, pending further successful pilots.

Cairn implemented EOR on a fast track, performing many development activities in parallel to achieve full EOR potential from MBA fields in 15-20 years. The reservoirs contain waxy and moderately viscous crude (9-22 cp) resulting in adverse mobility between oil and water. The field was originally developed using a hot waterflood. Even before Mangala development was initiated, engineers envisaged EOR potential.

EOR screening, studies

Conventional primary depletion and basic water flooding typically recovers 20-40% of STOIIP. EOR can add another 10-20% STOIIP. Polymers increase injected water viscosity, forcing injected fluid to move into more regions than plain water, resulting in a more efficient flood that increases production.

Additionally, small amounts of detergent-like surfactants also can be injected with water and polymers. These surfactants improve the sweep and oil displacement, enhancing oil recovery compared with water injection alone.

International consultants told Cairn that EOR screening indicated aqueous-based chemical flooding EOR would be most suitable for MBA fields. The addition of polymers minimized water’s tendency to finger through the oil.

Combined with alkali and surfactant chemicals, injected water acts almost as a soap, helping to wash more oil from the reservoir. The difference between PF and ASP floods depends on the combination of chemicals used.

Detailed laboratory studies have been conducted since 2006 at Surtek laboratories and at the University of Texas petroleum engineering department to quantify the potential of various chemical floods at MBA fields.

Cairn consulted with other laboratories to evaluate chemical flood potential for Bhagyam and Aishwariya fields. The main objective was to select suitable chemicals for core floods, to understand process mechanisms, quantify incremental gains over water flood, and recommend a chemical formulation for the pilots.

Another objective was to generate parameters specifically required by commercial chemical flood simulators. University of Texas at Austin (UT) researchers developed an optimal chemical formula for Mangala field. Most core floods demonstrated at least 95% recovery of total oil in the core.

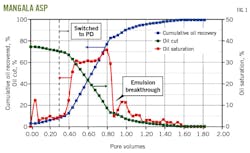

The optimal chemical slug based on several core floods was selected for field testing in the ASP pilot. Fig. 1 shows the Mangala ASP coreflood performance post-waterflood. Fluid injected is expressed in pore volume equivalent. An initial slug of ASP injection is followed by a chase polymer drive (PD).

EOR pilot

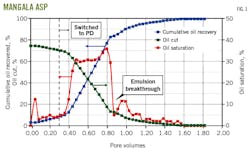

Cairn scheduled polymer flooding pilots and ASP pilots in quick succession under field-scale conditions. Simulation studies helped engineers design a pilot with four injector wells and a central production well.

The 5-spot pilot was implemented with water flood, followed by PF, and then an ASP flood to quantify the incremental recovery benefits of each. The pilot’s target zone was the uppermost unit of the Mangala reservoir, which contains 45% of total STOIIP.

Crews drilled three logging observation wells inside the pilot area to measure changes in oil saturation and assess the in situ conditions and progression of the flood. Fig. 2 shows the pilot pattern.

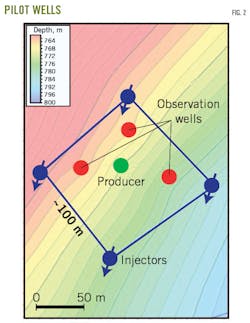

Cairn’s pilot started water injection in December 2010 and finished in July 2011 after the water cut rose to 70-75%.

Crews started polymer injection in August 2011 using a newbuild central polymer facility (CPF). PF response was as engineers expected with the water cut declining to 30% and staying at low levels for 4-5 months, indicating polymer injection improved sweep efficiency within the pilot, enhancing oil recovery.

Fig. 3 shows the polymer flood pilot in Mangala field. Researchers completed the polymer injection pilot in September 2012.

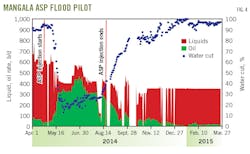

Pilot ASP flooding was restricted to the reservoir’s upper sand to control confinement, to effectively use chemicals, and to accelerate a higher oil cut. ASP flooding started in April 2014 with 0.5 pore volume (PV) of ASP slug injected into the reservoir.

After ASP flooding, crews injected 0.5 PV of PD followed by 0.1 PV of chase-water injection. Crews stopped the operation in February 2015 when the water cut consistently showed 98%.

The oil cut increased to 70-80% from 8% in 3-4 weeks. Peak oil cut continued for 2.5 months (0.45 PV). As expected, injected chemical breakthrough occurred just after water-cut reversal. Fig. 4 shows the performance of the ASP flood in Mangala field.

Researchers monitored injection water and fluid quality through laboratory analysis. Observation wells recorded time-lapse saturation logs (both carbon-oxygen logs and induction logs). In all three observation wells, both logs showed increasing sweep with time during the ASP pilot.

Tracers injected at the start of the baseline low-concentration polymer flood prompted Cairn to take corrective actions on nearby off-pattern wells to reduce interference on the pilot’s performance. Different tracers were injected at a later stage of the pilot. Tracer results showed connectivity to the pilot producer and improved sweep.

Injection chemical breakthrough occurred after water-cut reversal, showing favorable mobility throughout the flood.

Crews measured produced surfactant concentration by the titration laboratory method for quantitative chemical analysis. UT analyzed samples using a high-performance liquid chromatograph.

After ASP flooding, Cairn drilled two wells to extract cores. Sponge core barrels were used to preserve any fluid during reservoir-core extractions. Sponge material retains any oil that might expel due to changes in pressure and temperature. This helps determine accurate oil saturation in the core, an important parameter in measuring ASP flood success.

The cores were found to be well swept with only 10% average remaining oil saturation. Fig. 5 compares photos of cores obtained from a PF and an ASP flood.

Core shown from ASP flood zone (left) compared with core from PF zone (right). (Fig. 5).

Mangala polymer flood

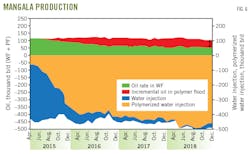

Based on pilot results, Cairn implemented full-scale PF in Mangala in November 2014.

A skid-based system initially was used for testing three [no need for this to be a number] well pads. Skid-based systems are small portable systems for chemical EOR solution preparation and injection that can be put in containers for installation during field tests.

The main CPF was commissioned in April 2015. It is the world’s largest polymer preparation facility with a maximum capacity of 100,000 b/d of 15,000 ppm mother polymer solution preparation, using almost 190 tonnes/day of polymers.

The mother solution is highly concentrated and diluted with water at the injection wells to get the required lower concentration polymer solution for injection.

The mother solution had an average viscosity of 3,000-3,500 cp. The solution is pumped to different well pads where it is diluted with injection water to prepare a final polymerized injection water having a wellhead concentration of nearly 2,500 ppm and viscosity of nearly 30 cp.

Field polymer injection was ramped up to target rate of 400,000 b/d of polymerized water by February 2016. Cairn accelerated the well hookup schedule to ramp up the polymer injection rate.

The Mangala polymer project stabilized within 1 year, making it one of the fastest and largest polymer flood applications worldwide. It produced 50,000 b/d of incremental oil as of April 2019.

Cairn’s aggressive EOR strategy enabled the Mangala recovery factor to reach nearly 30% of estimated STOIIP within 10 years. Fig. 6 shows the polymer flood performance in Mangala.

Cairn plans to expand Mangala ASP flooding through integrated contracts. The peak ASP injection is forecast at nearly 350,000 b/d of dilute ASP solution. Expansion plans require detailed logistics and supply chain planning to effectively manage the large volume of chemicals involved and to ensure chemical quality control.

Polymer flooding, already implemented across small areas of Bhagyam and Aishwariya fields, will be expanded to full-field scale starting mid-2019. ASP pilots are scheduled in parallel for those fields and, depending on pilot results, Cairn envisions large-scale expansion of ASP into them as well.

Bibliography

Beliveau, D., “Detailed Special Core Analysis Program: Key to Aggressive Field Development Planning, Rajasthan, India,” SPE Europec, London, 2007.

Pandey, A., “Refinement of Chemical Selection for the Planned ASP pilot in Mangala Field - Additional Phase Behavior and Coreflood Studies,” SPE IOGC, Mumbai, March 2010.

Pandey, A., Beliveau, D., Corbishley, D., and Kumar, M.,“Design of an ASP Pilot for the Mangala Field: Laboratory Evaluations and Simulation Studies,” Society of Petroleum Engineers (SPE) Indian Oil and Gas Technical Conference and Exhibition (IOGC), Mumbai, Mar. 4-6, 2008.

Pandey, A., Kumar, M., Beliveau, D., and Corbishley, D., “Chemical Flood Simulation of Laboratory Corefloods for the Mangala Field: Generating Parameters for Field-scale Simulation,” SPE Symposium on Improved Oil Recovery (SPE IOR), Tulsa, Apr. 20-23, 2008.

Pandey, A., Beliveau, D., and Kumar, M., Pitts M., and Surtek, J., “Evaluation of Chemical Flood Potential for Mangala Field, Rajasthan, India - Laboratory Experiment Design and Results,” International Petroleum Technology Conference, Kuala Lumpur, Jan. 1, 2008.

Pandey, A., Koduru, N., Stanley, M., Pope, G., and Weerasooriya, U., University of Texas at Austin, “Results of ASP Pilot in Mangala Field: A Success Story,” SPE IOR, Tulsa, 2016.

Prasad, D., Pandey, A., Koduru, N., and Kumar, M., “Pilot to full field polymer application in one of the largest onshore field in India,” SPE IOR, Tulsa, April 2014.

Pandey A., Kumar, M., Jha, M., Tandon, R., Punnapully, B., Kalugin, M., Khare, A., and Beliveau, D., “Chemical EOR Pilot in Mangala Field: Results of Initial Polymer Flood Phase,” SPE IOR, Tulsa, April 2012

The authors

Sanjay Kumar serves as Cairn Oil & Gas’s strategic business unit (SBU) president–MBA fields development. Working for Cairn for more than 17 years, Kumar leads Cairn’s EOR development. He was instrumental in planning the MBA PF and ASP floods. His expertise is in petroleum engineering, production technology, reservoir engineering, production optimization, and reservoir management. He started his career with Cairn in Chennai. He took a subsurface technical lead role in 2011 and has since led Cairn’s production optimization group, Bhagyam and Aishwariya development group, and Mangala polymer flood development group. Kumar received a B.Tech (2002) in petroleum engineering from Indian School of Mines, Dhanbad, and obtained his MS (2013) in petroleum engineering from Heriot Watt, Edinburgh, UK

Amitabh Pandey serves as Cairn Oil & Gas SBU subsurface head–MBA fields development. He has worked for Cairn for more than 14 years and has 28 years of oil and gas experience. He played a pivotal role in designing and implementing PF and ASP pilots in Mangala followed by full-field PF implementation in Mangala, and polymer injectivity tests in Bhagyam and Aishwariya fields. Pandey has expertise in complete life-cycle chemical EOR processes. He jointed Cairn in 2005 after having worked for ONGC at the Institute of Reservoir Studies (IRS) in Ahmedabad. For IRS, he worked in the Chemical Flooding Laboratory and Bombay High Development studies. Pandey obtained a B.Tech (1991) in petroleum engineering from the Indian School of Mines, Dhanbad.