Refinery exceeds industry benchmarks with maintenance outsourcing

Since it outsourced the maintenance part of its organization 2 years ago, Germany's Schmierstoff Raffinerie Salzbergen (SRS) lube oil refinery has achieved above industry average maintenance reliability.

Ferrostaal Industrial Plant Services, whose core business is maintenance, partnered with SRS at that time to manage the refinery's maintenance activities.

This partnership has led to an optimized cost structure in maintenance and spare-parts management and to an increase in plant availability. The result is maximized profitability of both partners's bottom lines.

SRS and Ferrostaal defined and carried out its outsourcing alliance by taking the following five steps. After the contract was developed (Step 3), the official outsourcing began:

- Analysis of the current maintenance performance of the refinery.

- Development of an optimization plan to bring the existing maintenance program to agreed upon benchmarks.

- Development of a service contract for outsourcing and implementation a change of management process.

- Execution and optimization of the maintenance program.

- Continuous innovation, improvement, and best practice application.

Analysis

After making the decision to outsource the maintenance function, the first step is to analyze the current maintenance performance. For SRS and Ferrostaal, this analysis took 14 days and 5 people from Ferrostaal. It covered the following maintenance areas:

- Strategy.

- Organization structure.

- Work planning, execution, and analysis.

- Purchasing and stores.

- Subcontractor handling.

- Health, safety, environment, and quality (HSEQ).

- Cost control and budgeting.

- Workload control.

- Analysis and reports.

- Shutdown and turnarounds.

- Maintenance management software.

- Training.

- Interfaces to production and other departments.

Detailed discussions of each item helped form an accurate picture of the current status of the maintenance organization, strategy, and overall performance. Should some interviewees have given false answers, the quantity of gathered data made it impossible for the organization to give a consistently wrong picture.

From the information gathered, the analysis team developed the optimization plan.

Optimization plan

SRS and Ferrostaal jointly developed an optimization plan by comparing the current performance (cost, efficiency, and plant availability) with international benchmarks and Ferrostaal maintenance data from other projects. The optimization concept aims at closing the gap between SRS's current performance and the leading maintenance performer worldwide.

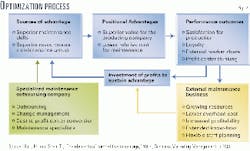

Fig. 1 shows how the complementing core business of both partners contribute to the bottom line.

The general items addressed in the optimization plan are:

- Transition process for the maintenance staff.

- Cost optimization.

- Optimization of plant availability.

- Establishment of external maintenance business.

The detailed areas for optimization are implementation of a maintenance strategy, weak point analysis for increased plant reliability, involvement of production in maintenance work, backlog management, and utilization of capacity for outside clients work.

After development of the optimization plan, operating companies decide if they want to continue or end the outsourcing program. A study of the optimization plan finalized SRS's decision to proceed with the project and develop a service contract.

Contract and change management

The service contract not only defined the contractor relationship but established a partnership between SRS and Ferrostaal. It covered the work to be performed by Ferrostaal as well as the expected results as defined in the optimization plan.

Further areas defined by the maintenance contract are the transfer of employees, the integrated teams between SRS and Ferrostaal, and the operation of the computerized maintenance management system (CMMS; created by JD Edwards and owned by SRS) by Ferrostaal.

On the commercial side, the contract uses an open-book policy which allows SRS to control the profit made by Ferrostaal inside the SRS plant.

A bonus/malus regulation for the maintenance budget assures the performance of Ferrostaal. The partners share budget overruns as well as savings up to a certain ceiling.

Table 1 lists specific savings from the previous budget, implemented upon Ferrostaal's recommendation.

Ferrostaal distributes a major percentage of budget savings to employees to provide incentives for performance. These incentives are given to both maintenance and production personnel from both companies to encourage partnership thinking.

Legally, the Federal Civil Code, paragraph 613a, covers the outsourcing process in Germany. Crucial items are the pension funds, salary structures, the change from weekly to yearly working time, and the change of the union. Hand-in-hand with the outsourcing is the change-management process (Table 2), which handles the conversion from cost-center to profit-center thinking and establishment of a new company culture.

Ferrostaal employed a new maintenance manager to facilitate the change-management process. Workshops among SRS, the outsourced maintenance crew, and Ferrostaal guided the process.

Prior to putting the outsourcing activities in practice, SRS implemented a communication plan to share its intent with employees. It is not unusual for outsourcing activities to create a high grade of uncertainty for employees involved.

Providing the key messages about the outsourcing project at the right time to the right people is crucial for success of the project.

Maintenance optimization

The Ferrostaal maintenance manager also headed execution of the maintenance optimization and the daily maintenance. His primary task was implementation of a maintenance strategy with the right mix of predictive, preventive, and corrective maintenance, supported by implementation of condition monitoring for critical equipment.

The new manager reviewed and pared down the number of existing subcontractors of SRS. The primary aim was to execute work by in-house maintenance staff where financially feasible. Thus, it was possible to increase the number of SRS maintenance staff after the outsourcing.

With an accurate backlog worklist, Ferrostaal and SRS understood the amount of future outside services needed.

Ferrostaal took over the shutdown and turnaround planning and execution, modification and modernization work, and handling of SRS spare-parts stock. Ferrostaal reduced the variety and quantity of spares by linking the stock to the predictive maintenance strategy, which defined the maximum and minimum levels of parts needed.

In its role as manager of daily maintenance, Ferrostaal budgeted and planned maintenance work. JD Edwards software handled the work orders. SRS owns the software and the maintenance data and considers it a strategic advantage for the plant.

The software reporting system provides ongoing data about plant reliability and budget for various areas of the plant, even at the equipment level.

Continuous improvement

An outsourcing process is successful only if it generates sustainable growth for the maintenance company. Fig. 2 describes an optimization process to achieve this goal.

Based on the existing strengths of the maintenance organization, which are assessed during the analysis phase, Ferrostaal added maintenance staff with skills and resources where necessary.

Sourcing best practice approaches from other plants and industries (steel, chemical, and paper), Ferrostaal generated positional advantages by offering SRS a lower relative cost at a superior value. The superior value must be related to the overall client strategy. For SRS, value was increased plant availability and reliability. The lower relative cost was the result of increased work efficiency and rationalization of the subcontractors.

The results of good performance are client satisfaction and increased loyalty. The loyalty and cooperation of production is also the result of a shared incentive system for the employees of both production and maintenance, each from different companies.

External market share is one of the most important performance outcomes. Employees of SRS's maintenance group also serve existing outside Ferrostaal clients, giving the maintenance company (formed when SRS outsourced maintenance) new projects outside of SRS. This leads to a more flexible staff planning and lowered overhead cost within SRS.

Ferrostaal invests generated profit in the maintenance company to sustain the advantages generated. At this point, the outsourced maintenance is converted from the cost-center to a profit-center organization.

Results

The approach has resulted in the joint achievement of the following goals by SRS operation and Ferrostaal maintenance:

- The mechanical plant availability is stable at 94.2%, well above the industry average. The Solomon study for lube oil refineries pins average mechanical availability of lube oil plants at 93.7%.

Ferrostaal committed in its contract to keep SRS's availability above the industry average.

- The number of maintenance staff increased from 38 to 43 during the 2 years after outsourcing began. Ferrostaal reviewed existing subcontractor contracts and employed new staff in situations when it was less costly than existing contracts.

Further, the new SRS maintenance company is employing about 10% of the staff for maintenance work, such as condition monitoring, normal repairs, or shutdown work, outside of SRS.

- The budget for normal maintenance decreased from 100% in 1999, when the project started, to 84% in 2000. Besides specifics listed in Table 1, Ferrostaal also reduced the budget by:

- Establishing a backlog for 14 days with non high priority work to eliminate idle time.

- Implementing a yearly working time instead of weekly working time. The maintenance staff can have ±140 hr of working time on their account and use these for holiday during periods with low work level. This reduces the overtime payments.

- Developing a joint training program for production and maintenance staff to reduce the cost for maintenance, which could also be done by operators.

- Developing joint teams for optimization programs between operation and maintenance. These teams meet every 4-6 weeks to ensure optimizations plans are implemented.

- Encouraging operations to prepare equipment before the maintenance group comes. This preparation includes removing insulation, taking out products, and disassembling cables.

- Changing the 15 min breakfast break to a 15 min break at the end of the day. This allows employees to finish 15 min earlier and reduces the time used to go to and from the canteen, which is 3-5% of the daily working time.

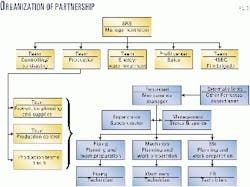

As shown in Fig. 3, maintenance optimization enabled both companies to focus on their core businesses. SRS's strength is producing and selling lube oil products, and Ferrostaal's core business is maintaining the plant.

During the daily business the SRS production teams interface with the Ferrostaal maintenance people at the working level. This approach minimizes administration and ensures just-in-time provision of services.

The authors

Steffen Simon is managing director of Ferrostaal Maintenance Nord GMBH. He is responsible for the ongoing maintenance optimization process within SRS and various other petrochemical and chemical maintenance projects in northern Germany. His 25 years' experience includes work with EKO Stahl, MAN AG, and Ferrostaal. Simon holds a PhD in plant organization/engineering from the University of Dresden, Germany.

Oliver Laubner is a project development sales manager for international business at Ferrostaal Industrial Plant Services. During the past 2 years, he was responsible for the establishment of outsourcing projects in Southeast Asia and the Middle East. He has more than 5 years' experience in the upstream and downstream industry with Dresser Industries, MAN AG, and Ferrostaal. Laubner holds an engineering degree from the University of Braunschweig, Germany, and an MBA from NIMBAS Graduate School of Management, in Utrecht, the Netherlands and Bradford, UK.