Revolutionary technologies

Technological advancements in the oil industry are often incremental improvements based on existing technologies. The refining industry, in particular, is mature from a technological standpoint.

For example, new refining catalysts almost always evolve from existing catalyst configurations, and the infrastructure is already in place to bring these new catalysts to the marketplace.

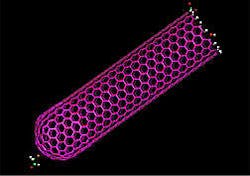

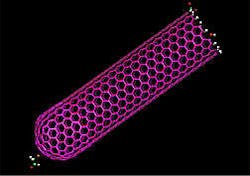

It is a rare opportunity, therefore, to find a technology in its infancy and watch it develop. Nanotechnology, or the nanotube (see photo) in particular, is one such revolutionary technology that holds great promise. Most people know nanotechnology as "buckyballs" or "fullerenes."

Individual nanotubes have several interesting and unique properties. The tiny structures are about one billionth of a meter in diameter, or about 1/50,000th the width of a human hair.

They are reportedly the strongest substance that will ever exist, with a tensile strength 100 times greater than steel, but at only one-sixth the weight. Nanotubes also have the electrical conductivity of copper and the thermal conductivity of diamond.

Technology commercialization

A company called Carbon Nanotechnologies Inc. (CNI) is at the forefront of the nanotechnology wave. Richard Smalley and Robert Curl, both Rice University professors, won the 1996 Nobel Prize for Chemistry for discovering buckyballs. Smalley co-founded CNI to help commercialize single-wall carbon nanotubes (buckytubes) and make enough of them to be used in industrial applications.

CNI has developed HiPco, a high-pressure process that uses carbon monoxide as the feedstock to create high-purity buckytubes. Currently, CNI makes about 40 g/day (g/d) of buckytubes it sells to companies that want to develop this technology in specific industries.

CNI and the oil industry

On Sept. 27, CNI announced it had signed an agreement with Kellogg Brown & Root (KBR) to advance the buckytubes technology farther. KBR will provide the conceptual and detailed design, fabrication, construction, and operation support. CNI also has leased lab space at KBR's technology center in Houston to build a larger manufacturing reactor, which will produce 200 g/d of the buckytubes.

The reactor will go on stream in early 2002. CNI hopes that the new unit will lower the cost of nanotubes, currently about $500/g. Lowering the price would help increase demand and spur more interest by companies looking to use buckytubes in unique applications.

Folks in the refining industry are familiar with KBR through its previous work developing process technologies, including advancements in ethylene cracking, fluid catalytic cracking, de- layed coking, visbreaking, and ammonia production.

Buckytubes and the future

CNI sees the most promising applications in the electronics, aerospace, and composite materials industries. And although there are not many projected applications in the oil and gas industry, new technologies always seem to gain applications in previously unthought-of ways.

When personal computers first came out, for example, everyone thought they would be a fad and wouldn't be able to replace mainframes. But as the technology developed, PCs became a multibillion dollar industry, and one that spawned further innovations in process controls.

So, who knows what could be in store for buckytubes? Indeed, it will be very interesting to watch this new technology as it finds its niche in different industries.