Subsea completions key deepwater Brazil development

With subsea completions tied to floating production vessels, Petrobras has successfully developed many large, billion-barrel recoverable, hydrocarbon accumulations found in deep water off Brazil.

But if other companies had been allowed to operate in these waters, it is possible that the technologies selected to produce from these fields would have differed.

One comment often heard is that, because over the years Petrobras has been operating floating drilling rigs continually in the area, it can easily divert these rigs to intervene and workover subsea well completions on relatively short notice, without excessive mobilization costs.

Other operators, having less access to drilling rigs, may prefer to develop fields with dry-tree options, such as tension-leg platforms (TLPs) and spars, which allow easier and less costly well intervention.

And even Petrobras may consider other production options. As Marcos Assayag, Petrobras R&D Center deepwater R&D program coordinator, says "Petrobras is not committed to either wet or dry completion solution alternatives in spite of its large experience with subsea completions. In fact, it will adopt the option that brings the best investment rate of return."

By some estimates, 33% of Brazil's recoverable hydrocarbon reserves lie in deep water, defined by Petrobras as between 300 and 1,000 m (980-3,280 ft), while another 35% of the reserves are in deeper water.

Sizable activity

Forecasts indicate that deepwater Brazil will continue to be a very active province for a number of years. According to a Douglas-Westwood Ltd. study, expenditures off Brazil will be more than $5 billion by 2004 (Fig. 1). Douglas-Westwood defines deepwater as greater than 300 m.

Although it sees investment in deepwater Brazil decreasing as a percentage of total worldwide deepwater investment to 24.4% in 2004 from 30.2% in 2001, in dollar terms it expects investment in deepwater Brazil to increase by 34.9% to 5.3 billion in 2004 from $3.5 billion in 2001.

Douglas-Westwood forecasts worldwide deepwater investment will almost double to $21.9 billion in 2004 from the $11.5 in 2001.

Some planned developments off Brazil include:

- Espandarte, 1RJS-499, Campos basin, onstream 2000, in 940-m water.

- BS-500, 1RJS-539, Santos basin, onstream 2001, in 1,595-m water.

- Caratinga, Campos basin, onstream 2002, in 922-m water.

- Marimba East, onstream 2001, in 700-m water.

- Albacora East, Campos basin, onstream 2003, in 1,200-m water.

- Frade, Campos basin, onstream 2003, in 1,141-m water.

- Caratinga, 1RJS-425, Campos basin, onstream 2004, in 925-m water.

- Marlim East, Campos basin, onstream 2004, in 1,250-m water.

These onstream dates may change as Petrobras itself continues to reorganize and bring in outside partners to help develop some of these fields. For instance, development of some of the fields may be delayed because Petrobras has been reported to have failed to come to terms with potential partners on the project.

One project going ahead is the development of the Barracuda and Caratinga fields. Halliburton obtained a lump-sum $2.5 billion engineering, procurement, and construction (EPC) contract further to develop these fields.

Halliburton says the work will involve drilling and completing 51 wells, fabricating and installing flowlines and risers, and building and installing two floating, storage, and offloading vessels (FPSO).

Brazil is also continuing projects to gather associated gas produced in the deepwater Campos basin. Its $ 850 million Cabiúnas project is designed to increase gas production by 6 million cu m/d.

Petrobras describes the Cabiúnas project as follows:

- Optimize associated gas production in the Campos basin, known as the zero flare project, by installing additional gas handling equipment on existing platforms. This will help maintain oil production while making good use of natural gas.

- Construct a gas pipeline from Roncador.

- Construct three other pipelines-two from Cabiúnas to Vitória and the Duque de Caxias Refinery, and the third supplying gas to thermopower plants and other industrial projects, particularly the gas-chemical complex in Rio de Janeiro.

Deepwater systems

Design criteria for selecting offshore development schemes are very sensitive to climatic conditions. Off Brazil, the weather is less severe than in the Gulf of Mexico and the North Sea but more severe than off West Africa.

In this milder climate, Petrobras has extensively installed spread-moored semisubmersible production facilities and more recently also gone to turret-moored floating, production, offloading vessels (FPSOs) that are less rugged than would be required for environments such as the North Sea.

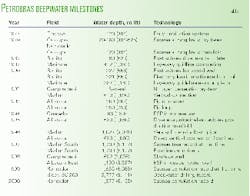

To produce Brazil's deepwater fields, at ever increasing water depths, Petrobras has also designed new technology. Table 1 lists some of its deepwater pioneering milestones, especially involving subsea systems producing to floating production vessels.

The deepest water in which it has drilled to date is 2,777 m (9,111 ft) on Block BC-200 in the Campos basin. The RJS-543 well was drilled by R&B Falcon Inc.'s dynamically positioned Peregrine IV drillship. According to Assayag, this was the third water-depth record established in the Campos basin during Petrobras' 1999 exploration campaign. He says there are no plans to produce from this well.

The well currently producing off Brazil from the deepest water is well RO-8, in 1,877-m (6,158 ft) water. The well is connected to Roncador Phase 1's permanent production unit that includes the P-36 semisubmersible floating production unit, moored in 1,360-m water. The P-36 transfers oil to the P-47 floating, storage offloading (FSO) vessel located in 815-m water. Production started in May 2000.

Petrobras says Phase 1 will have a total of 26 wells: 21 production wells and 5 injection wells. It intends to complete all the wells with subsea horizontal trees. Produced oil flows to P-36 through individual flexible lines. A gas export pipeline transports associated gas from P-36 to shore.

Two of Petrobras' previous water depth producing records were for the early production systems for the Marlim South well, MLS-3, completed in 1,709 m (5,127 ft) in 1997 followed in 1999 by Roncador RJS-436 subsea well in 1,855 m (6,086 ft).

The RJS-436 well produces to the Seillean dynamically positioned FPSO that dispenses with the need for a mooring system. Assayag says the Seillean is scheduled to depart from the RJS-436 well to a new location in December 2000. The RJS-436 well will then be linked to the P-36 production unit.

Subsea trees undoubtedly will continue to be the main stay for developing deepwater fields off Brazil, although new operators coming into Brazil, such as Texaco Brazil Ltd., may prefer dry tree systems.

Texaco has announced that its base-case scenario for developing the Frade field, in 1,141-ft water, envisions the dry-tree option with a spar-type floating production platform. But Texaco adds that the final decision on the development scheme still depends on additional drilling results. In October 2000, it plans to begin drilling its first well in a three well delineation program on the Frade field.

One technology being tested by Petrobras for producing deepwater fields is the subsea electric submersible pump. The company installed one on June 2, 1998, in the Albacora East well RJS-477, in 1,109-m water. The pump has been operating continually since then, pumping 3,500 bo/d, according to Assayag.

The Albacora East well was Petrobras' second subsea ESP installation. The first in much shallower 86-m water was in the Carapeba field. The ESP in RJS-221 well was installed in 1994, and Assayag says it has produced for 2 years and 10 months with at initial rate of 1,300 bo/d.

Petrobras installed its first deepwater subsea multiflow meter in June 1997 in the Albacora field. Petrobras deployed the meter inside of a guidelineless retrievable module in the subsea production manifold, in 450-m water, to measure production from the MSP-DL3 well, 4.5 km from the P-31 FPSO.

Assayag says this prototype meter has been operating since May 10, 1999, and has performed as expected.

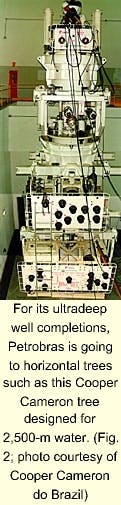

New trees

Petrobras is going to horizontal trees for its ultradeep completions. It says these subsea trees have the following benefits:

- Allow higher flow rates because of the large diameter production strings, greater than 5 in., that can be placed in the wells.

- Save rig time by eliminating the need of blowout preventers for some well workovers.

- Allow replacement of the production string without needing to remove the subsea tree.

Petrobras is preparing to run the first subsea horizontal trees designed for 2,500 m water depth (Fig. 2) on a well in Marlim South field in September 2000.

The 2,500-m subsea SpoolTree system, manufactured by Cooper Cameron do Brazil, is a diverless tree, installed without any guidelines. Cooper Cameron has designed it to land on 163/4 in. by 10,000 psi wellhead and for the material mechanical properties to allow service in high hydrogen sulfide (H2S) concentrations.

The design provides a vertical connection flowline system to land the flowline modules on the tree. Cooper Cameron says one main characteristic of this dual 5 in. by 2 in. tree is the fact that because of the water depth, it will be installed using a dynamically positioned rig with a guidelineless (GLL) 163/4-in. blowout preventer system.

Besides the prototype tree, Cooper Cameron says Petrobras has contracted for five more of its trees, of which two are suitable for oil production with CO2.

The total stack height including tree, tree cap, wireline blowout preventor, and quick disconnect tool is about 10 m. Total weight of the test bases, transportation skid, and the subsea equipment is about 150 tons.

The tree has a 51/8-in. production and 21/16-in. annulus bore. All hydraulically operated gate valves are fail close and have a hydraulic override to be operated by an ROV, which allows mechanical operation in case of problems with hydraulic supply lines. The production tubing string is suspended by a tubing hanger set inside the spool body of the tree.

A drill pipe riser will be used to install both the tree and tubing hanger. To allow lifting operations, the weight of the tree in air must be less than 30 tons.

Flowlines are connected through a hydraulic flowline connector and the outboard hub assembly for the control lines, for production and annulus flowlines. The design considers the flexibility to install the flowlines independently of the tree.

The design incorporates three separate vertical connection modules because of the water depth and the high loads needed during the flowline and umbilical installation.

Cooper Cameron has designed the tree and other components for a 20-year life.