Environmental index quantifies reservoir characteristics

An easily calculated semiquantitative index, which expands on conventional sample-description procedures, may be used to indicate relative levels of porosity and permeability while drilling.

In turn, this information can be used to supplement or even supplant costly and time-consuming drillstem or formation pressure-test data, further enhanced by the addition of invaluable geologic feedback.

This second of a three-part series on mudlogging technologies focuses on poly-modal sample-description techniques, providing real-time clues to reservoir characteristics. The conclusion will describe theory, techniques, and equipment for determining gas content in coal seams.

A new procedure

Conventional mudlogging operations utilize visually subjective and uni-modally restrictive techniques to determine the textural characteristics of drill cuttings, ignoring basic sedimentologic analyses that otherwise can be used to depict reservoir quality.

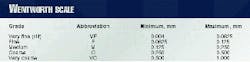

For example, grain-size depiction at the wellsite depends on homogeneously discrete divisions defined by the Wentworth Scale (Table 1). The problem with this qualitative approach, however, is that it provides the geologist with a narrow assessment of grain size, either medium or fine.

Sample sizes, however, are rarely one or the other but instead are a poly-modal combination of grain sizes. This problem extends to other textural features such as angularity, sorting, cementation, and porosity (see box: Textural considerations).

On the other hand, a new approach allows the conventional analysis of drill cuttings to be transformed from qualitative (e.g., coarse) to semiquantitative (Index = 23) values through the application of an environmental index (patent pending).

This method begins with the following procedure:

- 1. Assign numerical weighting factors to each of the discrete grain size divisions containing larger values for larger grain sizes, preferably in the range of 1-5.

- 2. Classify the proportions of the cuttings' constituents between discrete grain-size divisions, preferably a total of 10.

- 3. Multiply the classified proportions by the corresponding weighting factor. This step establishes values representative of the relative contribution to the formation's porosity.

- 4. Sum the relative contributions for each grain size division. This step establishes numeric values corresponding to the porosity of the formation.

Assessing permeability

In the next step, relative permeability for each sample can be semiquantified as follows:

- Determine numerical values for the proportion of grains in each of a plurality of grain-size divisions.

- Apply a weighting factor to each corresponding division, establishing an environmental index value (EnviroNdx).

- Assign a numerical value as to the degree of grain angularity, establishing an angularity index value (AngNdx).

- Assign a numerical value as to the degree for which the grains are the same, establishing a sorting index value (SrtNdx).

- Assign a numerical value as to the degree from which the sample grains bind together, establishing a cementation index value (CemNdx).

- Assign a numerical value to the degree of porosity of the sample, establishing a porosity value (Por).

- Calculate the relative permeability index (PermNdx) of the sample as being substantially proportional to EnvNdx, AngNd, SrtNdx, and Por and inversely proportional to CemNdx, stated as follows:

PermNdx = EnvNdx x (AngNdx)2 x (Srt Ndx)2 x Por/(CemNdx)2

Weighting

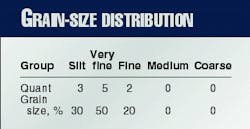

For the purposes of developing an environmental index, each sample is assumed to have an arbitrary total grain grading score of 10, representative of 100% of the individual proportions for each of the five grades listed in Table 1.

It is also recognized that coarser grain sizes, which in many cases proportionally impact porosity and permeability, contain a greater energy level. Accordingly, the method assesses sampled grain grades on an increasingly weighted system as it shifts from very fine to very coarse material, demonstrated as linearly increasing, yet arbitrary values of 1 to 5.

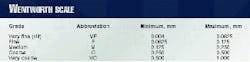

As such, this weighting system provides a strong indicator of permeability, provided that permeability increases with coarseness. For example, if a sample is graded as 20% fine and 80% coarse, with none of the other grades present, the environmental index can be calculated by multiplying and summing the assessed percentage for each grain size distribution by its corresponding weight (see box: Environmental index calculations).

In comparison, this can be evaluated against a sample that contains 80% fine and 20% coarse grains where the former index of 36 is deemed more permeable than the latter index of 24.

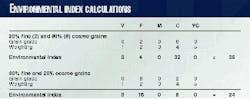

In Fig. 1, two samples contain a combination of grain grades with the left sample containing a lot of fine, some medium, and a small amount of coarse material, while the right sample consists primarily of coarse grains.

Describing the samples conventionally, wellsite personnel would assume that medium-sized grains dominate the left sample while coarse grains dominate the right. Unfortunately, this assessment does not provide a fair appraisal of the two samples for it does not properly portray representative depositional energies, relative porosities, or permeabilities.

With the environmental index, however, and with reference to Fig. 1, the five grades can be set forth, assigning weighted values of 1 through 5. The left sample then contains about 10% very fine, 60% fine, 20% medium, and 10% coarse material while the right side contains 80% coarse and 20% very-coarse material. Through the application of these weighting factors, the left sample would then achieve an environmental index of 23 compared to 42 for the right sample.

Thus, rather than applying the unweighted Wentworth Scale to depict only the average overall grain size, the samples can now be used to compare potential energy levels. In this case, the right sample displays twice the value of the left sample, demonstrating a proportional increase in its potential for permeability.

The environmental index further assists in avoiding the misinterpretation of anomalous cuttings where drilling operations encounter vugular or otherwise porous or permeable formations.

With conventional methods, unless the analyst recognizes that the finer portion of the crystalline material was derived from a vugular feature within a coarse formation, then an analyst would only have a limited choice for sample grading if he or she used traditional grain-size grading techniques.

Thus, the geologist or mudlogger would likely grade the sample as very fine and then improperly indicate low porosity on the log, where instead, the overall formation would actually consist of high-porosity streaks.

On the other hand, with the environmental index, all the grain sizes in the sample would be represented in the calculation, eliminating the analyst's bias that is based on a visual assessment of the major constituents. Thus, it becomes possible to account for the sample's entire compositional makeup then relate it to permeability.

This technique also provides a numerical value that can be easily compared from sample to sample or included in further calculations of relative porosity and permeability. In even more preferable embodiments of the invention, conventional qualitative characteristics can be similarly quantified.

Canadian case study

In a recent well drilled by Mobil Oil Canada in the Bluesky formation of Canada, geologists used the distribution of textural ingredients such as grain size, angularity, and sorting to assess the environmental index.

The process began with wellsite personnel collecting lagged samples from the shale shaker, prewashed with either water for water-based drilling mud or diesel for oil-based mud. Next, the samples were sieved, clear washed, spine dried, then final dried with radiant heat.

Using a microscope, the geologist then counted sandstone grains to gain a representative distribution for all fractions. For example, a sample collected in the interval 2,052-2,065 m contained the grain-size distribution as shown in Table 2.

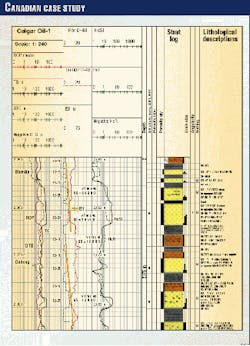

Angularity, sorting, and other textural indexes (Fig. 2, 6th track) were additionally defined and entered into the computer, generating the environmental index column as shown in the second track of Fig. 2 (green line).

Successive samples collected throughout the siltstone, sandstone, and shale intervals showed a clear correlation between penetration rates and the hydrocarbon saturation index (OGJ, Jan. 24, 2000, p. 32), lending strong support to the gas logs and drilling parameters.

In addition, the analyst established trend lines, marked in orange, which indicated relative increases in the environmental index from zone to zone. For example, the interval from 2,070 to 2,085 m in the Gething formation shows a visible increase with depth, indicating a relative increase in permeability downward.

Taken one step further, the environmental index, in combination with the angularity index, sorting index, porosity, and cement index can be used to calculate relative permeability. It should be noted that sample collection frequency plays a very large role in determining reservoir quality.