Erika effect to chill use of older tankers, report says

The wreck late last year of the tanker Erika off the coast of France (OGJ, Dec. 20, 1999, p., 38) is chilling shipping-industry attitudes about using older tankers, especially those with hydrostatic ballast loading (HBL).

That's according to a special report issued last month by Poten & Partners, New York, as an update to its earlier study of tanker prospects.

The "Erika effect" deflates the tanker-oversupply bubble in 2001 and afterwards with commensurate effects on rate forecasting and newbuilding activity.

The Maltese-registered tanker Erika broke in half in a storm about 100 km off the northwestern coast of France Dec. 12 and spilled 10,000-18,000 tonnes of heavy fuel oil. It prompted an outcry from the public and European governmental officials.

The vessel apparently had several problems. It was 24 years old and had changed owners often. It had received a safety check from Italy's verification bureau Registro Italiano Navale (RINA) on Nov. 24, 1999, in Sicily, but was reportedly sent to RINA after Bureau Veritas (BV), Paris, had declared it unfit to carry any cargo until an overdue safety check had been performed (OGJ, Jan. 24, 2000, p. 28).

(The accompanying sidebar relates progress on clean-up following the incident.)

Adjusting attitudes

The Erika incident is affecting how oil-market participants and oil importing and exporting nations think about old tankers, said Poten & Partners' update report.

The firm's longer study of tanker prospects had built certain assumptions into its projection of tanker supply. Focusing on very large crude carriers (VLCCs), the assumptions included continued relatively low bunker fuel prices and a willingness of oil companies to use some VLCCs that employ hydrostatic ballast loading (HBL).

The update report says low bunker prices kept old turbine VLCCs as cash cows, while use of some carriers with HBL extended the lives of some vintage tankers from 25 to 30 years under MARPOL phase-out provisions.

HBL involves the loading of a cargo so that its surface remains below the waterline of the tanker, Poten & Partners told Oil & Gas Journal. If the tanker ruptures its bottom and does not list, the seawater pressure at the bottom of the tank is greater than the pressure exerted by the oil cargo, which prevents oil from leaking from the tanker.

The chief criticism of HBL, said the firm, is that the conditions leading to a rupture of a tanker's bottom may also lead to a condition, such as severe listing or rupture extending to the sides of the tank, whereby seawater pressure cannot hold the cargo in the tank.

Such were the conditions at the time Erika wrecked.

Accelerated phase out

Following the incident, Poten & Partners re-examined the phase-out schedules of VLCCs at their 25th and 30th anniversaries, respectively. The original forecast had assumed oil companies would utilize VLCCs with HBL to the extent necessary to ensure an adequate supply of VLCC tonnage in order to keep rates reasonable.

This has been changed by the Erika incident, says the update report.

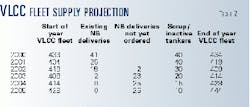

The number of VLCCs at the end of the waiting line because of age considerations will grow as new vessels are delivered. These ships may not actually be scrapped, the report says, but they will be "quasi-scrapped" either by being laid-up or waiting at loading areas for cargoes that rarely come their way.

Some vintage tankers in excellent physical and operational condition will continue to be employed with HBL. But, says the report, "The Erika effect has reduced the potential use of HBL."

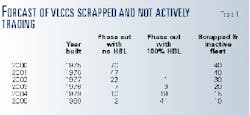

Inactive tankers listed in Table 1 include those actually laid-up and those in quasi-layup awaiting cargo. Either way, they are effectively removed from active service, says the report.

The table shows two phase-out schedules representing two extremes: No use of HBL phases out all VLCCs at 25 years of age; 100% use of HBL phases out all VLCCs at 30 years of age. Poten & Partners' assessment of the future number of inactive tankers, including those scrapped, laid up, or forever awaiting a cargo, is in the right-hand column.

TotalFinaElf SA last month awarded the contract for neutralization of the cargo in the wrecked tanker Erika to a consortium of CSO International, a unit of Coflexip Stena Offshore Group, and Stolt Offshore, according to CSO International.

The scope of work includes recovery and neutralization of what crude oil is still confined in the two parts of the wreck in about 125 m of water, off the Finist

What's to be done

The three main offshore operations will include:

- First, a complete survey of the two parts of the wreck, which are 10 km apart, to investigate their condition and ensure safe performance of the work.

For these surveys, CSO will use one of its subsea construction and diving support vessels, the CSO Constructor, and deploy remotely operated vehicles (ROVs), particularly the Triton XL that in February conducted a survey for TotalFinaElf.

- Second, preparation of the two parts of the wreck prior to pumping operations with the installation of valves using the "hot tapping" solution that allows safe drilling of the hull without leakage.

CSO International says this option is frequently used to operate on oil and gas pipelines without stopping the flow of oil.

The consortium simultaneously will use two dynamically positioned diving support vessels, the CSO Constructor on the bow and the Stolt Offshore Seaway Kestrel on the stern, to install and test all underwater structural process, instrumental, and pumping systems designed by TotalFinaElf, and to connect these hot taps to the surface.

- Finally, the pumping operation will be performed according to the process developed by TotalFinaElf, using a well test and early production dynamic positioning vessel, the Crystal Ocean, with a 6,000 cu m storage capacity.

The CSO Constructor will assist the pumping vessel for all subsurface operations with her diving and remotely operated capabilities, says CSO International. Products recovered (crude oil mixed with the methylester of colza through the pumping systems will be stored on the pumping vessel and transported ashore by batch via shuttle tankers to the disposal site.