Shale gas, oil, minerals processing offer synergies in Brazil's Amazon basins

Fabiano Sayao Lobato

Consulting Geophysicist

Kingwood, Tex.

The Amazon region of Brazil is a trove of hydrocarbons and world class mineral resources, and the use of hydrocarbons to process its mineral resources could be the basis for sustainable economic development. The potential for both hydrocarbons and minerals is already immense even though the area is minimally explored.

Horizontal drilling coupled with hydraulic fracturing can change the exploration outlook for hydrocarbons in the Amazon basins. Add to this the possibility of carbon dioxide injection to enhance oil recovery and a large avenue is open for utilization of vast mineral resources for sustainable development of the regional and national economies.

The processing of minerals into usable products generates CO2 in a symbiotic sequence. The more minerals processing, the more CO2 generated which in turn liberates more hydrocarbons for processing.

This article reviews the underexplored potential of both the hydrocarbons and minerals and points to the synergistic opportunity of simultaneous or sequential development.

An important characteristic of the Brazilian Amazon is its size (Fig. 1). The Upper Amazon basin stretches for 625 miles west-east. The Middle and Lower Amazon basins extend 1,650 miles west-east. Separating the Upper and Middle basins is the Purus arch, which roughly follows the Purus River. The city of Manaus, population 2 million, is on the left margin of the Negro River near its junction with the the Amazon River. The Negro River is the Amazon's largest tributary.

The Amazon is called is called the Solimoes River west of Manaus and Amazonas east of Manaus.

The Amazon sedimentary basins are entirely covered by tropical jungle that also extends to the north on the Guianas Precambrian Shield and to the south on the Brazilian Precambrian Shield.

The hydrocarbon potential of the Amazon area is immense and has components of conventional structural, stratigraphic, shale oil, and shale gas expressions. The mineral potential is also vast and will be detailed in this article for iron, aluminum, copper, potash, manganese, titanium, niobium, and quartz.

Amazon hydrocarbon potential

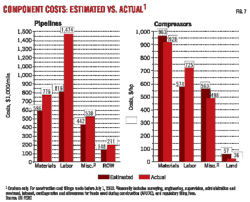

The main source rocks in Amazon basins are the Barreirinha member of the Devonian Lower Curua formation and the Pitinga member of the Silurian Trombetas formation (Fig. 2).

The Barreirinha reaches a depth of 10,820 ft (Fig. 3) and a thickness of 500 ft (Fig. 4), and the Pitinga reaches a depth of 12,140 ft (Fig. 3) and a thickness of 500 ft (Fig. 5).

Fig. 6 shows total organic carbon and maturation zone distribution for the Barreirinha. At the RCM-1 well drilled by Shell Oil Co.'s Pecten International Co. subsidiary in 1982 about 63 miles southwest of Manaus, TOC was measured at 15%.

Fig. 7 shows TOC and maturation zone distribution for the Pitinga. In the Upper Amazon basin as well as in most Lower Amazon basin, this unit is overmature.

Both source rocks underlie 136 million acres in the Middle and Lower Amazon basins and 74 million acres in the Upper Amazon basin.

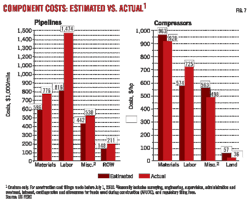

Scores of exploratory wells were drilled in the Amazon basins through October 1984 (Fig. 8). The main concentrations of wells are in the productive Jurua and Urucu fields of the Upper Amazon basin and in the area southeast of Manaus in the Middle Amazon basin. In the Upper Amazon basin the density is around one well/1.3 million acres. In the Middle-Lower Amazon basins it is one well/1 million acres. Many development wells have been drilled in the two fields.

Historical background

The Nova Olinda stratigraphic well was drilled on the right margin of the Madeira River 100 miles southeast of Manaus in 1953-55.

The location was chosen near the center of the Middle Amazon basin where a barge bringing the drilling rig could reach. This well produced 15,000 bbl of high-quality light oil and created the expectation of other discoveries because it was more than 1,000 miles from nearest production in Venezuela.

Petrobras was created by Law 2004 of Oct. 3, 1953, and took over hydrocarbon exploration from Brazil's National Petroleum Council, which had DeGolyer & McNaughton as consultant. The first head of exploration of Petrobras was Walter K. Link, assisted by Luis G. Morales as chief geologist. Both came from Standard Oil of New Jersey, where Link was chief geologist and Morales was chief geologist in Colombia.

Petrobras was under pressure to produce results in view of the accidental oil discovery at Nova Olinda. Many wells were drilled without proper seismic/geologic support, which was out of reach due to the jungle cover.

Seismic work was conducted along the rivers, but data quality was poor. Besides problems properly locating lines, reverberation from river margins masked the data, and the seismic energy reduced fish populations.

Surface geologic study was limited to outcropping north and south of the basin because the center was covered by decoupled Tertiary and Cretaceous sediments. Tropical jungle covered everything, thus limiting use of aerial photography.

Nevertheless, geological information from wells permitted recognition of a very encouraging petroleum system with world class source rocks at proper maturation (Figs. 2-7). The main problem was paucity of reservoir rocks.

Structural and deformational system

A transcurrent fault may have existed during the Late Jurassic Oxfordian 160 million years ago and persisted until the Cretaceous (Fig. 9).

To the figure from Prof. Scotese, the author added the possible Riedel conjugate system, which has implications to deformation of the sediments. The transcurrent fault may be the result of differential movements of the Guiana Shield, north of the Amazon basins, and the Brazilian Shield to the south.

Fig. 10 illustrates the explanation of three directions of compression associated with the transcurrent fault and Riedel conjugate faults. Starting from a circle at the top of the figure, deformation of sediments creates an ellipse of which the axis AA′ corresponds to an extension of the radius of the circle and the axis BB′ corresponds to a reduction of the radius of the circle.

An extension would submit the sediments to extensional faulting in a direction perpendicular to AA′ BB′. Compression in the principal axis direction BB′ would create a system of cylindrical folding with horizontal axis (lower Fig. 10). Similarly, the left lateral Riedel conjugate CC′ would create the left lateral compression, and the right lateral Riedel conjugate DD′ would create the right lateral compressional system.

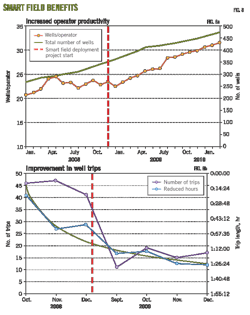

Fig. 11 shows the Amazon model with superposition of horizontal cylindrical folding in the principal axis and Riedel conjugate axes. The bottom of Fig. 11 is expanded as Fig. 12, where highs are surrounded by lows.

The author mapped 65 four-way anticlines each 2,470 acres to 24,700 acres in the 2 million acre region southwest of Manaus. The mapping preceded the development of a possible explanation for the observed deformation.

Considering that the prospective area of the Upper Amazon basin is 74 million acres and the area of the Middle-Lower Amazon basins is 136 million acres, the potential for exploration would involve 6,500 structures if the rate observed in the mapped area southwest of Manaus persisted throughout. It is important to emphasize that this is a speculation indicating only the order of magnitude of the potential for structures.

Fig. 13 shows the structural framework of the Middle-Lower Amazon basin. Of note is the concentration of anticlinal folds in the center of the figure which are aligned with similar concentrations near Manaus, in the west Middle Amazon basin, and the Urucu-Jurua trend in the Upper Amazon basin.

Of extreme importance is the mapping of Precambrian transcurrent faults both north and south of the sedimentary section that are aligned across the sediments. These faults correspond to the Riedel conjugate system suggested on Fig. 11. The right lateral component on the east end of Fig. 13 has been mapped starting in the Precambrian and was extended on the sedimentary area. The northeast/southwest faults correspond to the left lateral Riedel conjugate. All of the preceding supports the interpretation of transcurrent faults in the Amazon basins and the possibility of a multitude of simple four-way culminations surrounded by low structural features.

This system extends 1,550 miles east to west.

Transcurrent faults have a predominantly vertical surface component that could be the conduit for the molten basaltic magma from the earth mantle to the sediments above. Fig. 2 indicates the existence of diabase sills in the Silurian, Devonian, and principally in the evaporite section in the Carboniferous and Permian. The age of the diabase is principally Triassic-Jurassic.

The intrusion of the molten magma is facilitated by assimilation of evaporites, thus creating space for penetration.

There is no mention of basalt in the description of rocks in the wells, which would indicate extrusion of magma for surface cooling (which occurs at the Parana basin of southern Brazil). Only diabase is described, which would indicate slow cooling within the sediments.

In any case, the magma intrusion corresponds to a thermal pulse that complements the maturation of source beds. Fig. 14 shows the thermal effect of diabase sills on maturation measured at the 1-LUC-1-AM well in the Petrobras Urucu field. Vitrinite reflectance decreases with depth as the distance to the diabase sills increases. Likewise, the thermal effect of diabase along the transcurrent fault surface (near vertical) decreases with distance.

Amazon hydrocarbon exploration myths

This brings up two myths that prevailed in early hydrocarbon exploration in the Amazon basins.

First, was the conclusion that no structures existed because the well information suggested persistence of bed thicknesses over large distances. Because the seismic data were so bad, the broad structures could not be detected. It was only after the seismic technology evolved that the multitude of structures could be recognized. As indicated earlier, thousands of simple four-way anticlines may be interspersed with lows.

The second myth was that the molten magma injected, principally in the Triassic and Jurassic, destroyed all hydrocarbons. What occurred was an increase in the degree of maturation, but hydrocarbons survived as demonstrated by accumulations in the Urucu and Jurua areas.

At the Jurua area, the Monte Alegre formation equivalent (Fig. 2) produces mainly gas, despite being shallower than at the Urucu area, which produces oil, condensate, and gas. The explanation is that in the Jurua area the diabase sills are closer to the source layers (Lower Curua, Pitinga, Fig. 2) than in the Urucu area.

The two ideas are myths, and this fact enhances the potential for hydrocarbons of the Amazon basins.

In the Upper Amazon basin, reserves are estimated at more than 4 tcf of gas and more than 500 million bbl of oil.

Production is 40,000 b/d of oil and 160 MMcfd of gas. The gas feeds power plants at Manaus via a 410-mile pipeline inaugurated on Nov. 26, 2009.

Oil shale

The outcropping Barreirinhas member of the Devonian Lower Curua is considered oil shale at the south margin of the Amazon sedimentary basin.

Concessions and production

Fig. 15 shows the Amazon mineral deposits as depicted on the site of Brazil's National Petroleum Agency (ANP).

More than 250 million bbl of 59° gravity, low-sulfur oil have been produced from Urucu field. Oil was discovered in the 1970s, and production started in 1982. Some produced gas was initially reinjected to maintain reservoir energy, but much of it was flared. Nowadays it generates electricity at plants in Manaus and along the pipeline route.

Petrobras in early 1999 revealed a discovery that appears to be the reason behind ANP's award of 11 million acres of concessions to Petrobras in the Middle Amazon basin east of Manaus (Fig. 16). Outside the Petrobras blocks are 177 million acres available to other operators in the Middle/Lower Amazon basin.

The company said at that time, "Petrobras specialists found a a gas-bearing formation 12 m (39.4 ft) thick, at a depth of 1,650 m (5,412 ft), 200 km (124 miles) east of the city of Manaus, the capital of the state of Amazonas. After carrying out the required tests, specialists determined that the 20 sq km (4,949 acre) area holds a production potential of 700,000 cu m/day (24.7 MMcfd) of gas with a small percent of condensate. It is estimated that the mapped area contains about 8 bcm (282 bcf) of gas in place, representing recoverable volumes of around 6 bcm (211 bcf)."

High Resolution Technology (HRT) Oil & Gas, headed by Marcio Rocha Mello, obtained a concession covering 12.1 million acres, all or parts of 21 blocks, surrounding the Urucu and Jurua areas in the Upper Amazon basin in 2009 (Fig. 16). HRT has announced a major seismic and exploratory drilling program there.

Amazon mineral potential

The Amazon region has world class mineral deposits already identified and possibly many more awaiting exploration.

The principal accumulations involve iron, manganese, copper, gold, nickel, aluminum, and potash, besides the volcanic chimneys. Many are potential markets for gas.

Iron, manganese, copper, gold, and nickel

The Carajas Mineral Province is already considered the largest mineral province in the world (Fig. 15).

More than 18 billion tons of iron ore averaging 66% of iron content have been measured. Production started in 1983 and reached 90 million tons/year in 2009. It is projected to increase to 200 million tons/year by 2015 (personal communication from Breno Augusto dos Santos, the discoverer of Carajas).

Manganese ore production is 2 million tons/year. The Brazilian company Vale SA has installed copper concentrate capacity of 300,000 tons/year with 100,000 tons of contained copper from the Sossego mine. By 2011 the Salobo mine would contribute 127,000 tons of contained copper with 130,000 oz of gold. There is no production of nickel at present, but in 2011 the Onca mine will start production of 58,000 tons of contained nickel in iron-nickel ore.

Bauxite and aluminum

Production of high-grade bauxite started at the Trombetas mine in August 1979 (Figs. 15 and 17). The reserves were estimated at 1 billion tons of bauxite containing around 50% of alumina or 25% of aluminum. At present, Trombetas produces 16 million tons/year of bauxite. Cumulative production is 250 million tons.

The 4 million tons of aluminum derived from the 16 million tons/year of bauxite corresponds to 10% of world output of new aluminum. New aluminum is specific for foil and special applications. The annual world consumption is 80% recycled aluminum and 20% new aluminum from bauxite. To produce recycled aluminum takes about 5% of the amount of energy needed to produce aluminum from bauxite.

The aluminum industry has five phases. The first is the mining of bauxite, the ore used in most refineries. Refineries are industrial installations that extract alumina (Al2O3) from bauxite and constitute the aluminum industry second phase. In the third or metallurgical phase, aluminum is obtained by electrolysis from alumina in smelters. The fourth phase is the production of semimanufactured goods, and the final phase is the production of finished goods.

In an effort to reduce cost by eliminating bulk transportation, by-products should be disposed of at the mine site. This also results in reduction of pollution by dumping the red mud generated by processing of alumina in the natural filtering system that produced the bauxite. This effort has defined a trend to move the first three phases from industrialized countries to countries that have high-grade bauxite deposits.

Based on parameters provided by A.L. Bacon (Billiton) and Raymundo Campos Machado (Alcan, retired), computations were made for processing 1 million tons of bauxite of the type mined at Weipa (Australia), Boke (Conakry, Guinea), and Trombetas (Brazil). It takes around 4 tons of bauxite to produce 2 tons of alumina (Al2O3) and 1 ton of aluminum.

The yearly demand for gas for the processing of 1 million tons of bauxite would be 350 MMcf for bauxite drying, 4.9 bcf for alumina, 550 MMcf for aluminum, and 31.25 bcf for electrolysis, or a total of 37.05 bcf/year or 101.5 MMcfd.

Other bauxite accumulations

The Alcoa-operated Juruti mine (Fig. 15) started production in 2008 of 2.8 million tons/year of bauxite. The mine will expand production to 10 million tons/year. The announced reserves of the Juruti area are 750 million tons of high-grade bauxite.

The Jari project, 400 km east of Trombetas, has 1,500 million tons of bauxite. Other deposits of bauxite are indicated on Fig. 18.

Bauxite processing

Alumina/aluminum plants near Belem and Sao Luis are supplied with electricity by the 9,600 Mw plant at the Tucurui dam on the Tocantins River (Fig. 15).

At 100 MMcfd/1 million tons/year of bauxite for processing at the mine site, the potential demand is 2.6 bcfd to process to aluminum the combined 26 million tons/year of bauxite to be produced at Trombetas and Juruti.

Potash demand

Potash helps improve crop quality and a plant's disease resistance, reduces plants' water needs, and increases yields. There are no practical substitutes for potassium as an essential plant nutrient.

Potash occurs in the Amazon area of Brazil as sylvinite, a mixture of sylvite (KCl) and halite (NaCl) (Figs. 15 and 17). The Fazendinha/Nova Olinda deposit (450 million tons of sylvinite) and Ararí deposit (550 million tons of sylvinite) measured by Petrobras mining branch, Petromisa, are recognized as potassium ore bodies. The Petrobras FA-1 well near Trombetas detected 5 m of sylvinite, but no extra drilling was made to confirm an exploitable ore body.

The potassium deposits occur in the evaporite expanse that extends for 500 km by 200 km (Fig. 18). The potential for many potassium ore bodies is quite good because Fazendinha/Nova Olinda, Arari, and Faro were discovered by accident upon drilling for hydrocarbons inside the evaporites.

Potash processing

Beneficiation of sylvinite ores is done by froth flotation since the middle 1930s. In the US and Canada, the fuel for froth flotation is natural gas. Because in the Amazon region of Brazil the shale gas source beds and the potassium ore beds occur in the same area, there is no need for construction of long pipelines.

The location of plants for processing the ore can take advantage of this situation and make the operation more economical. Also, the availability of rivers navigable by ships of 75,000 tons capacity minimizes the cost for transportation of products to markets everywhere.

Importance of potash to Brazil

Brazil imports 90% of the potash it consumes. Consequently, it is of interest to Brazil not only to exploit the ore bodies already discovered but to find new ones.

The size and distribution of evaporites in the Amazon region as expressed by the 1 billion tons of sylvinite already measured, plus the Faro occurrence, indicate that Brazil could not only become self-sufficient in potash but could become an important exporter.

Volcanic chimneys

In 1973, the National (Brazilian) Department of Mineral Production (DNPM) launched the Project RADAM-Brazil of side-looking radar to cover the Amazon region.

Images were cataloged of over 200 volcanic chimneys (the exact number is 207 announced by the then-DNPM director Acyr Avila da Luz at the 1974 Brazilian Geological Society meeting at Porto Alegre).

Three volcanic chimneys were drilled and sampled:

1. Seis Lagos (Six Lakes) carbonatite. Located in the Upper Rio Negro, it is considered the largest accumulation of niobium (NB2O5) and contains 1.0% to 2.1% of cerium (used on cars' catalytic converters), barite, and manganese (Fig. 18).

2. Maicuru alkaline-ultrabasic complex (Fig. 19). Located 155 miles northeast of the Trombetas mine, where preliminary exploration indicated a potential of around 5 billion tons of titanium ore under the form of anatase (TIO2), possibly the world's largest titanium accumulation.

3. Maraconai alkaline-ultrabasic complex, covered with titanic/magnetite crust and located near the Paru River 185 miles northeast of the Trombetas mine (Fig. 20).

Three of the more than 200 volcanic chimneys drilled indicated two of the largest accumulations of niobium and titanium, respectively. One can only guess at how many large mineral deposits could be discovered in the undrilled volcanic chimneys.

Halite-caustic soda

The production and processing of potash (KCl) results also in the production of large quantities of halite (NaCl). In turn, by electrolysis, halite produces caustic soda (NaOH) and chlorine.

Caustic soda is used in producing alumina (AL2O3). Plastics are produced by using methane and chlorine.

Thus, the separation of potash from sylvinite results in a sequence of industrial processes of importance.

Glass, cement, and ceramics

Of interest, the Amazon River carries large quantities of quartz under subaquatic dunes.

The concentration of quartz was measured by the University of Amazonas in excess of 94% in the moving sediments. The dunes travel downriver as much as 500 m/day.

The quartz already reduced to sand could be the basis for a glass industry, which in turn would require energy from hydrocarbons for processing.

The bauxite at Trombetas occurs encased in clay deposits with the appropriate composition for ceramics and production of cement. Both could be economically produced because the clay would already have been mobilized for the extraction of bauxite and has low production cost.

Minerals/hydrocarbon strategy

The area encompassing the Trombetas and Juruti bauxite mines and the FA-1 well potassium occurrence is indicated for the start of possible shale gas production.

At present, Trombetas and Juruti together produce close to 19 million tons/year of high grade bauxite, but this production is expected to increase to 26 million tons/year within 5 years.

As in the energy requirements for the aluminum industry, it takes 100 MMcfd of gas to process to aluminum metal 1 million tons/year of bauxite. Thus, the ultimate demand for the aluminum industry is around 2.6 bcfd of gas to be supplied by shale formations. Of course, this production has to start slowly and grow as needed, but it indicates the immense potential for the development of a shale gas industry. Along the way, it is quite possible for conventional and stratigraphic hydrocarbon accumulations to be discovered and also put on production.

The amount of sylvinite at the area around the FA-1 well has not been measured, but the thickness of potash at the well is 16.4 ft, which corresponds to 13 million tons/sq km if the thickness persists. Natural gas is needed to thermally process the separation of sylvite from halite as seen in the processing of potash above.

The titanium ore deposit at Maicuru (Fig. 19) is 110 miles northeast of the Trombetas mine. The processing of titanium ore to metal also requires large volumes of gas.

Quartz exists in large quantities in subaquatic dunes in the Amazon River near the Juruti mine, which could support a large glass industry. Also, clay deposits at Trombetas mines could activate major cement and ceramics industries.

Thus, if natural gas can be produced from the source beds at the location of the above deposits, the pipelines required to supply very large industrial minerals development would be quite short.

Nearly 2.5 million acres are open within 100 km from the Trombetas mine and could be licensed to start a major industrial development that could be greatly expanded. Thus, the use of hydrocarbons to process the mineral resources of Amazonia could be the basis for sustainable economic development.

Acknowledgment

Thanks to Ana Carolina Naves Crema for the graphic presentation.

Bibliography

Mossmann, R., Falkenhein, F.U.H., Goncalves, A., and Nepomuceno Filho, F., "Oil and Gas Potential of the Amazon Paleozoic Basins," AAPG Memoir 40, 1986, pp. 207-41.

Lobato, Fabiano S., "Exploration for Hydrocarbons in the Amazonas Basin," Brasil Mineral, Special Issue 2000, pp. 33-37.

Caputo, Mario V., Solimoes Megashear, Intraplate Tectonics in Northwestern Brazil," Petrobras Magazine, Vol. 7, No. 24, January/February/March 1999.

dos Santos, Breno A., 1981, "Amazonia, Potencial Mineral e Perspectivas de Desenvolvimento," T.A. Queiroz, ed., Editora da Universidade de Sao Paulo, 1981, 257 pp.

da Luz, Acyr A., "Morro dos Seis Lagos," Brasil Mineral, No. 191, Janeiro/Fevereiro 2001, p. 29.

Neves, Carlos A.O., "Boletim de Geociencias da Petrobras," Vol. 4, No. 1, 1990, p. 98.

Bacon, A.L. (Billiton), and Machado, R.C. (Alcan), "Parameters for Energy Requirements for the Aluminum Industry," personal communications.

Singleton, Richard H., "Mineral Commodity Profiles," MCP-11, US Bureau of Mines, February 1978.

Briefing Brazilian Agriculture, "The Miracle of the Cerrado," The Economist , Aug. 28, 2010, pp. 58-60.

Fick, Jeff, and Jelmayer, Rogerio, "Vale Strenghthens Its Grip With Copper Offer," The Wall Street Journal, July 30, 2010, p. B3.

Tita, Bob, "South America Beckons to U.S. Firms," The Wall Street Journal, July 30. 2010, p. B4.

Paris, Costas, and Welsch, Edward, "Interest in Potash Mounts," The Wall Street Journal, Sept. 8, 2010, p. B1.

The author

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com