Residual magnetic fields reduce pit depth

Jose Hiram Espina-Hernandez

Victoria Venegas

Francisco Caleyo

CIDIM-Instituto Politecnico Nacional

Mexico City

Alma Valor

Universidad de la Habana

Havana

Jose Manuel Hallen

CIDIM-Instituto Politecnico Nacional

Mexico City

| Based on presentation to ASME’s International Pipeline Conference, Calgary, Sept. 27-Oct. 1, 2010. |

A statistical survey of coupons under the influence of a residual magnetic field shows reductions in both general pit depth and extreme pit depth values compared with control coupons not under the influence of a magnetic field. Scanning electron microscope micrographs show coupons subjected to remanent magnetization on the order observed in pipelines after a magnetic-flux leakage inspection develop pits with corroded areas around them. The corroded areas extend over the surface and can link the pits in a generalized corrosion pattern.

A leakage magnetic field appears inside the pit and in its vicinity. Magnetic finite element simulations show areas of higher magnetic gradient along the pit border, and the magnetic gradient force increasing linearly with the radius of the growing pit.

The gradient magnetic force acting on the paramagnetic ions removes them from the pit bottom, reducing their concentration at the bottom and hence their role in maintaining stable pit growth. The paramagnetic ions attracted to areas of higher magnetic gradient help increase surface corrosion around pits and produce a generalized corrosion pattern not observed in the nonmagnetized samples.

Background

In-line inspections based on magnetic-flux leakage (MFL) routinely detect and size metal loss and mechanical anomalies in operating oil and gas pipelines. MFL technology, however, leaves a remanent magnetization of the pipeline wall after inspection.

This article studies the influence of the magnetic field on pitting corrosion in pipeline steel. Pitting corrosion experiments occurred on samples of API 5L Grade 52 steel under magnetization of the same order of magnitude left by remanent magnetization in the pipeline wall after MFL inspection. Rings of the investigated steel magnetized the samples. The closed magnetic circuit configuration guaranteed the samples kept the same magnetization for the duration of the conducted experiments, reproducing the conditions observed in MFL-inspected pipelines in which the magnetic field was confined to the pipe WT.

The samples underwent pitting immediately after magnetization by immersion in a solution with dissolved Cl– and SO4– ions for 7 days. Nonmagnetized specimens acted as control samples.

Investigation showed the magnetic field confined within the pipeline wall influencing the pitting corrosion process. Statistical assessment of the pitting corrosion data showed the magnetic field reducing both the average depth of the pit population and the extreme pit depth values predicted from the maximum values observed in the magnetized samples. Scanning electron microscopy showed the residual magnetic field altering pit morphology by increasing the pit opening or mouth.

This article provides experimental evidence of the influence of the pipe wall’s remanent magnetization on the pitting corrosion process in pipelines inspected using MFL in-line inspection (ILI) tools. The most relevant characteristic of the study is that the magnetic field is zero outside the material, preventing the solution from being influenced by the magnetic field until pits originate.

Finite element simulations demonstrated the role of the leaked magnetic field in pit depth reduction caused by the forced movement of paramagnetic species toward zones of higher magnetic gradients.

Remanent magnetization

After MFL inspection the pipeline wall shows a residual magnetic field with a magnitude varying according to the strength of the applied magnetic field, the inspection tool configuration, and the magnetic properties of the pipeline steel.

Fig. 1 shows the magnetization process during an axial MFL tool run. If the pipe wall is initially demagnetized, each point of the pipe wall will undergo a magnetization change according to the flux path in the magnetic circuit formed by the MFL tool and the pipe wall. The MFL tool has a set of permanent magnets arranged in such a way as to produce a flux path traveling through the pipe wall and the back iron, which closes the magnetic circuit.

If the pipeline has not been previously inspected by an MFL tool, each point of the pipe wall will suffer a negative field with respect to the flux direction at the Hall sensor. The field strength here can magnetically saturate the pipe wall. Once the MFL tool is moving forward, the magnetic field reverses its polarity, reducing the residual magnetic field in the wall. Once a pipeline is inspected by an MFL tool, therefore, the residual magnetic field (BRm) is less than the remanent magnetism (BR) of the pipe steel.

If a reverse magnetic field is applied as described, with a magnitude smaller than the coercivity (HC) of the material, the magnetization curve will follow a return branch once the MFL tool moves forward. Fig. 2 shows the hysteresis loop of an X52 steel obtained along the axial direction of the pipe. A particular return branch (in red) drawn over the loop serves as an example. This return branch depends on a particular reverse magnetic field strength, but all possible return branches cause a remanent magnetization (BRm) below the retained magnetization (BR) of the material (Fig. 2).

Measuring the residual magnetic field in an X52 pipeline with 219 mm OD inspected by an MFL tool in February 2005 occurred in May 2007. The residual magnetic field in the pipeline wall was about 300 milliTesla (3 kiloGauss). Hysteresis measurements performed on similar X52 steel shows BR ≈ 850 milliTesla along the axial direction of the pipeline.1

Experimental

The ion concentration of the immersion solution used in the present pitting corrosion experiments was selected from a previous work,2 in which a field survey of soil properties from southeastern Mexico was conducted and their influence on pitting corrosion of buried pipeline investigated.

The soil properties having greatest influence on pit growth are soil pH, Cl– content, and SO42– content. Table 1 shows the ion concentration of the immersion solution used for this article.

Preparation of 1 sq cm coupons from API-5L Grade X52 pipeline steel exposed the pipe’s external surface. Mechanically grinding the coupons yielded flat samples, which were polished with silicon carbide papers up to 1,200 grit, a 0.3 μm alumina polishing suspension, and cleaned ultrasonically in methanol for 3 min immediately before immersion in the corrosion solution.

The same pipeline section provided several 1 sq cm cross-sectional rings. A slot cut in each ring the same length of the studied coupons held them in place, forming a closed magnetic circuit when one of the investigated coupons was inserted and emulating real-life pit initiation conditions in pipelines with remanent magnetization.

A coil of 680 turns of 32 American wire gauge wire wrapped around each ring, leaving the zone close to their slot exposed. A direct current of about 2.2 amp supplied to its coil, produced a magnetic field of the order of 3 kiloamp/m confined in the closed magnetic circuit formed by the ring and the coupon. The ring-coupon system remained magnetized following removal of the power supply and the rings were immediately immersed in containers with the corrosion solution.

| Immersion in corrosion solution followed magnetizing of the test samples. Nonmagnetized control coupons were immersed in the solution for the same exposure time as a basis for comparison (Fig. 3). |

Fig. 3 shows the testing ring-coupon and immersion setup. Nonmagnetized control coupons were immersed in the solution for the same exposure time as a basis for comparison.

Removing the coupons from the rings and ultrasonically cleaning them in methanol for 15 min followed exposure. The dried coupons lay in a desiccator until they were used for pit depth measurements. A Nikon Epiphot M-156 optical microscope with a micrometric screw coupled to the focus measured pit depths. Focusing on the bottom and the surface around the pit and taking the difference between the two micrometric screw positions measured each pit depth at 100× magnification. Pits with a depth smaller than 5 μm were excluded. Scanning electron microscopy, using a SEM JEOL-6300, characterized the corroded surfaces.

Results

Fig. 4 shows observed and fitted distributions of the pit population of the nonmagnetized and magnetized coupons. This figure shows the pit depth distribution in the magnetized coupons shifted to the left in comparison with that observed in nonmagnetized control coupons.

The maximum (Max) and mean (M) values of pit depth in magnetized coupons (Max = 69 μm, M = 25.7 μm) are smaller than the values (Max = 111 μm, M = 36.4 μm) for the control coupons. These results suggest that following pit initiation, the magnetic flux leakage within and near nucleated pits reduces their growth.

In many practical pitting corrosion experiences, either in laboratory or field conditions, only the maximum pit depth observed in each coupon or exposed pipeline section is measured and recorded.3 Extreme pit depth values follow the Gumbel distribution for maxima.3 Extreme value statistics commonly couple with pit-depth growth modeling to predict the failure risk of in-service components and structures.

Fig. 5 shows the Gumbel distribution fitted to the observed maximum pit depths for both types of experiments. As expected from the results presented in Fig. 4, the Gumbel distribution fitted to the data for the magnetized coupons shifts to the left of the distribution obtained for the nonmagnetized coupons. The magnetic flux leakage produced by the corrosion pit alters the electrochemical activity within the pit, provoking a reduction in both pit growth and depth.

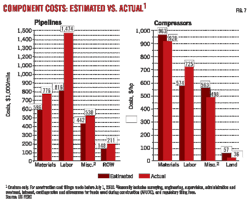

Figs. 6 and 7 show SEM micrographs taken from two coupons immersed in the solution for 7 days; nonmagnetized and magnetized, respectively. The micrograph of Fig. 6 shows corrosion pits with diameter 50-120 μm and a well-protected area surrounding each pit. These areas are associated with the cathodic regions of the active electrochemical-pitting-corrosion cells.

Fig. 7, in marked contrast shows a SEM micrograph from a magnetized coupon with a residual magnetic field in the range 300-500 mT (3-5 kg). Pits show diameters slightly larger than pits in the nonmagnetized experiment. Pits with diameter larger than 150 μm, however, show a corroded area around them. The surrounding areas (normally cathodic regions) of the larger pits are now corroded, showing that while pit growth is inhibited, surface corrosion accelerates. Surface corrosion initially occurs around pits but eventually covers the entire coupon, the merging of initially isolated areas becoming clear (Fig. 7).

Many pits with diameter smaller than 100 μm on the magnetized coupons also show only a reduction in depth and not the corrosion pattern observed for the larger ones.

Pitting mechanism

Pitting corrosion is an electrochemical process that can be described in detail by three distinct stages: a first step leading to breakdown of passivity, the early stages of pit growth with and without repassivation, and finally, stable pit growth. The corrosion process consists of at least two associated charge transfer reactions, metal oxidation and reduction of corrosion agents.

Fig. 8 illustrates the two-reaction pitting corrosion process. This electrochemical process involves movement of electrons within the metal and a recombination of ions. A high concentration of aggressive anions within the pit is requisite for maintaining pit corrosion. The precipitation of a paramagnetic salt layer is responsible for impeding repassivation and maintaining an active pit.4

Once a magnetic field is present where the electrochemical reaction occurs, a magnetic force Fmag is exerted on the involved ions. Fmag is better described by the field-gradient paramagnetic force FνB. FνB proportional to CjB∙νB and moves volume elements of paramagnetic species with concentration Cj toward regions of higher magnetic flux density.

Immediately after a pit initiates, the local environment and any surface films on the pit-initiation site are unstable, with a high concentration of hydrogen ions, chloride ions, or other ions responsible for initiating the local attack. In the pitting of a metal by an aerated sodium chloride solution, rapid dissolution occurs inside the pit, while reduction of oxygen takes place on adjacent surfaces (Fig. 8).

This process is self-sustained, or autocatalytic, and the rapid dissolution of metal inside the pit produces an excess of positive charges in the area, causing migration of chloride ions into the pit. A high concentration of paramagnetic salts (FeCl2, FeCl3, or MnCl2) exists inside the pit, helping maintain pit growth by avoiding repassivation of the pit’s metal surface.

The forces acting on the chemical species involved in the corrosion process depicted in Fig. 8 explain the magnetic field’s role in pitting. On the one hand, the magnetic flux leakage and the magnetic gradient inside the pit have no influence on the mass transport of the chloride ion, which is diamagnetic. On the other hand, the paramagnetic salts responsible for the stability of the pit suffer from the paramagnetic force, attracting the chloride ions out of the pit and toward the pit mouth rim, where the maximum magnetic field gradient lies.

Finite element simulations performed with the freeware FEMM5 demonstrated the influence of the magnetic gradient inside the pit on the paramagnetic salts. A closed magnetic circuit configuration modeled using a small ceramic magnet with horseshoe-shaped steel emulated the real corrosion conditions in the laboratory (Fig. 3).

This ceramic magnet guaranteed a magnetic flux density on the order of 0.4 Tesla inside the coupon. Simulation runs determined the distribution of the magnetic flux leakage inside and near pits with different dimensions on the surface of the modeled coupon. Pits were considered to have a perfect semicircular form.

Fig. 9 shows a snapshot of one of the FEMM simulations, in which a pit with a diameter of 12 μm was simulated. The resulting plot clearly shows the magnetic flux leakage and the magnetic gradient reaching maximum at the edges of the pit on the sample surface. The red line along the pit-mouth diameter shows the contour used to obtain the distribution of the absolute magnitude of the magnetic flux leakage in the pit mouth.

Simulations also showed (Fig. 10) that the maximum magnetic flux leakage for pits with radius 12-52 μm lies at the pit edges. The magnetic gradient force, FνB, acting on the paramagnetic salts helps move the aggressive ions out of the pit bottom and toward the pit edge. FνB’s effect increases linearly with the pit radius (Fig. 10). The numerical results, as obtained by finite element simulation, support the statistical results and the observed morphology of pits under the influence of a remanent magnetization.

Fig. 11 illustrates pit depth reduction caused by magnetic flux leakage in a growing pit. Initially, FνB attracts a certain amount of MnCl2 and FeCl2 salts toward the pit edge and impedes, although not totally, the precipitation of these salts at the pit bottom. Following that, as the pit grows, FνB increases to a certain critical level beyond which the growing process is impeded by the draining of these salts out of the pit and towards its edge. This process seems to help reduce pit depths and to corrode the areas surrounding the pits.

The magnetic field gradient at the pit edge in the depletion of the protective iron oxides layer could also contribute to the corrosion pattern observed on the magnetized coupons (Fig. 7). This process needs considerable investigation and the postulations are given as a possible mechanism without further investigation.

References

The authors1. Grossinger, R., Keplinger, F., Mehmood, N., Espina-Hernandez, J.H., Araujo, J., Eisenmenger, C., Poppenberger, K., and Hallen, J.M., “Magnetic and microstructural investigations of pipeline steels,” IEEE Transactions on Magnetics, Vol. 44, No. 11, pp. 3,277-3,280, November 2008.

2. Velazquez, J.C., Caleyo, F., Valor, A., and Hallen, J.M., “Predictive model for pitting corrosion in buried oil and gas pipelines,” Corrosion, Vol. 65, No. 5, pp. 332-342, May 2009.

3. Rivas, D., Caleyo, F., Valor, A., and Hallen, J.M., “Extreme value analysis applied to pitting corrosion experiments in low carbon steel: Comparison of block maxima and peak over threshold approaches,” Corrosion Science, Vol. 50, No. 11, pp. 3,193-3,204, November 2008.

4. Strehblow, H.H., “Mechanism of Pitting Corrosion,” Corrosion Mechanism in Theory and Practice, Ch. 8, p. 243, edited by Marcus, P., Marcel Dekker Inc., 2002.

5. Mekeer, D., “Finite Element Method Magnetics,” Version 4.0, user’s manual, http://femm.foster-miller.net/, 2006.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com