POINT OF VIEW: Unexploited oil resources continue to attract technology innovations

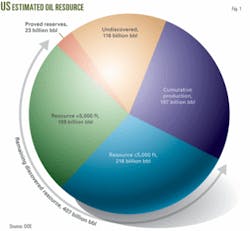

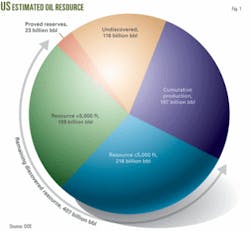

Over the years the oil industry has developed many technologies for improving oil recovery, yet much unexploited oil still remains in the ground. For instance, a US Department of Energy estimate made in the early 2000s says that the US has 407 billion bbl of remaining discovered resource that lie dormant (Fig. 1).

The US government has stopped most funding for research or demonstration projects for developing new ways for recovering these resources.

The government funding that remains is mainly through the Energy Policy Act of 2005. The act set up the public-private Research Partnership to Secure Energy for America (RPSEA) that has $50 million of funding provided from a US royalty fund. RPSEA’s primary focus is on research projects for recovering offshore oil and gas and unconventional gas and not for enhanced oil recovery. DOE’s National Energy Technology Laboratory administers the RPSEA projects and also has access to 25% of the funding for projects such as methane hydrate research.

DOE also contributes to the biennial Society of Petroleum Engineers/DOE Improved Oil Recovery Symposium in Tulsa. This year’s event will be held on Apr. 19-23 at Tulsa’s Renaissance Hotel and Convention Center.

IOR-EOR technologies

Bill Lawson, chair of this year’s IOR symposium, said the 2008 edition of the biennial symposium promises to be the biggest and best in years.

Lawson retired in 2006 as director of the Strategic Center for Natural Gas & Oil at DOE’s National Energy Technology Laboratory. He currently is the director of technology commercialization at the University of Tulsa.

Lawson noted, “The symposium’s theme reflects the shrinking base of new field discoveries, as well as the mounting number of maturing fields worldwide. Together with sustained high oil prices, national policy changes in some oil-producing countries in managing and producing their own resource, and the consequential migration of multinational oil companies to greater participation in more-mature fields have again increased the focus on secondary and tertiary oil recovery technologies and practices worldwide.”

He also noted that “Detailed reservoir knowledge available today allows companies to develop fields with greater confidence.” For instance, he said that in the US early attempts with chemical flooding were partly driven by tax credits that led to injecting various “witches’ brews.” But now the industry has the technology and knowledge to characterizing reservoirs more precisely and delineate the heterogeneities that are much more pronounced than previously believed, he added.

Controlling water flow from reservoirs is one of the major aspects of IOR and is featured at the Tulsa symposium, he said. Lawson added that another event at the symposium is a session on surfactants and polymers that will highlight the efforts in China’s Daqing oil field, which is said to be the “world’s largest field experiment in IOR/EOR.”

As far as EOR, Lawson noted such technologies as injecting CO2 hold potential for increasing recoveries but in the US CO2 availability is limited and currently there are no economic incentives for industries, such as power plants, to capture CO2.

He estimated that captured CO2 from industrial sites would need a sales price in the range of $1-1.50/Mscf to make it economical for EOR projects. But without carbon tax schemes and cap-and-trade legislation that would provide incentives for CO2 capture, captured CO2 availability for EOR is not on the horizon, he noted.

Power plants that use coal gasification technology could provide CO2 at lower costs because the CO2 already is at higher pressure and is more readily separated than at conventional coal power plants. But Lawson said that he knows of no firm plans in the US for building such plants in areas close enough to oil fields that could use the CO2 for EOR.

Because of escalating costs of such plants, the US government also has abandoned its plans to build the FutureGen coal gasification demonstration plant.

People

Although new technologies continue to provide new ways to extract additional oil, Lawson said that the lack of qualified people to do the work remains a major impediment for implementing the technology.

Also he added that he feared much knowledge from earlier studies and work may have been lost because of the reduction in the workforce during the last few decades.

Career highlights

William F. (Bill) Lawson became the director of technology commercialization at the University of Tulsa in September 2007, where he champions the identification, development, and marketing of the university’s intellectual property. He is also engaged in consulting on energy and management issues through his Tulsa-based company, Mountaineer International LLC. Lawson worked for more than 31 years with the US Department of Energy, most recently as the Director of the Strategic Center for Natural Gas and Oil at the National Energy Technology Laboratory from 2002 until his retirement in January 2006. There he oversaw the natural gas and oil research and development implementation activities for DOE’s Office of Fossil Energy. During 1998-2002, he served as Director of DOE’s National Petroleum Technology Office in Tulsa.

Education

Lawson has a degree in applied physics from West Virginia University.

Organizations

Lawson is chair (2007-10) and Oklahoma delegate to the energy resources and technology committee of the Interstate Oil and Gas Compact Commission. He also is general chair of the 2008 SPE/DOE Improved Oil Recovery Symposium. Lawson is a member of SPE and AAPG.