Technique improves exploration efficiency, exploitation safety offshore Myanmar

Ou Chenghua

Southwest Petroleum University

Chengdu, China

A technique known as rapid fault-sealing forecast of offshore fault systems (RFSFOFS) has improved exploration efficiency and exploitation safety of fault blocks in oil and gas fields.

Operators seeking to understand complex structure characteristics and development features of fault blocks often have limited data and quantitative forecast results.

This article presents an RFSFOFS methodology developed on the basis of sand-shale juxtaposition probability (SSJP) and normal-stress analysis on fault plane (NSFP) methods.

The author formulated an RFSFOFS methodology to forecast lateral and vertical sealing capacities of offshore fault systems by integrating static and dynamic data from faults around Well A1 on Block 1 in the eastern Andaman Sea off Myanmar.

Fault-sealing analyses helps operators make economic decisions and plan platform design as they decide whether to develop a particular block.1 Faults seal reservoir fluids, both laterally and vertically, in geologic traps.2 3 These seals often mandate operators drill a well for each individual fault block, adding to drilling costs and platform-design complexity.

Sealing forecasts also can help operators implement safe development strategies to help prevent marine environmental catastrophes, such as the Macando oil spill off Louisiana in the US Gulf of Mexico (OGJ, June 21, 2010, p. 22) and the Bohai Bay oil spill off China (OGJ, Sept. 12, 2011, p. 24).

RFSFOFS methodology addresses the following structure and development concerns:

• High costs associated with offshore activities limit the extent of drilling, well logging, fracturing, and well tests. Expenses and project schedules demand that operators extract as much information as possible from limited data.

• Sealing or nonsealing of faults directly affects the strategy, safety, and efficiency of offshore field development. The existing qualitative forecast often is insufficient.

• Thin interbeds within complex oil-bearing systems often influence fault-sealing properties, requiring the RFSFOFS methodology to distinguish significant variations of rock properties laterally and to identify uncertainties that thin interbeds impose upon the fault-sealing forecast.

• Offshore development requires rapid reservoir assessment.

Lateral, vertical forecasting

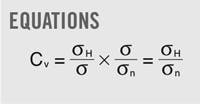

Sand-shale juxtaposition probability (SSJP) is the probability that the target sandstone is sealed by the juxtaposed shale in the fault zone. A probabilistic method is used to reveal the thickness variations of the drilled sandstone and shale, based on which vertical distribution model of sand and shale can be constructed (Fig. 1).

Juxtaposition probability and the sealing coefficient can be calculated.3 4 5 Multiple random simulations enable reservoir engineers to map the sealing coefficient and sealed frequency of the juxtaposed wall to the target wall, creating a quantitative forecast diagram for lateral sealing of faults (Table 1).

Ideally, an impermeable formation seals the reservoir. Realistically, layers on one fault wall do not necessarily correspond with layers on the other wall, complicating the forecast because the sealing capacity varies.

Oil and gas entrapment requires an impermeable capping formation. Only the upper half of the reservoir is evaluated when underlying water exists.

The author used sealing coefficient to evaluate lateral sealing of the reservoir. It shows the ratio of sealed thickness to total thickness of the upper reservoir (Table 1).

Capturing statistics usually involved running more than 100 simulations to draw a histogram. Lateral sealing was considered the most likely fault sealing probability.

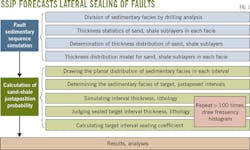

Describing a 3D in-situ stress model by its vertical maximum and minimum horizontal stress can forecast vertical sealing. Vertical-stress contributors include the gravity of the overlying formation and sea water. Horizontal stress stems from a combination of gravity-induced stress and tectonic stress.

Fracturing rock samples can determine stress directly. Inversion techniques to calculate the stress of rock deformation and properties can do so indirectly.6 7 8

It's difficult to test stresses by individual layer, preventing widespread application of expensive stress measurements. Inversion techniques based on well-logging data, however, can provide more continuous data sets at less cost. By integrating available core samples with abundant well logging data, the stress inversion technique becomes an effective NSFP method (Fig. 2).

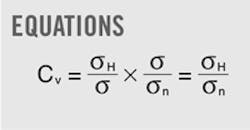

The higher the plastic flow of the shale in a fault zone, the stronger the vertical fault sealing. Vertical sealing coefficient, CV, the ratio of the formation deformation rate to the shale deformation rate, provides the index to determine the degree of fault sealing. The equation in the accompanying box expresses CV. The formation deformation rate is the ratio of fault-plane normal stress, σH, to the formation yield stress, σ, and the shale deformation rate is the ratio of the formation yield stress, σ, to the unconfined shale yield stress, σn.

Table 2 lists the NSFP methods criteria.

Methodology applications

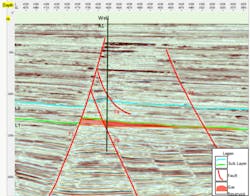

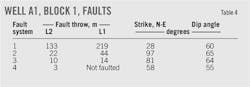

The Block 1 offshore fault system is in 101-152 m of water. Well A1 was drilled in 112.6 m of water having a density of 1.04 g/cu m. The well was drilled with caliper, acoustic, density, neutron, and dual-lateral logging. Penetrating Sublayers L2 and L1 (Table 3) revealed four faults (Table 4, Fig. 3).

Lateral-sealing forecasting based on well-logging data interpretation provided the basis for a formation sedimentary sequence model. The author used statistical analyses to determine a probability distribution function for sand and shale thickness. A fault profile was simulated.

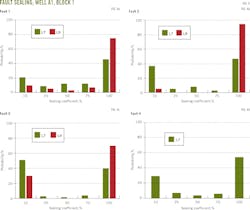

The SSJP method repeated a sealing coefficient calculation for each layer up to 150 times, plotting the probability histogram (Fig. 4) needed to make a lateral fault-sealing forecast (Tables 1, 5).

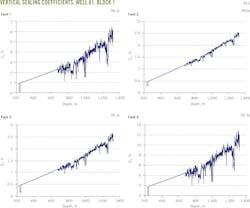

The vertical sealing forecast for Block 1 used available data to determine the directions of three in-situ stresses. Static and dynamic Poisson ratio, fluid pressure, vertical stress, and Biot coefficient were calculated using Well A1 fault depth, seawater depth and density, drilling records, and logging data. Applying Anderson's theory of stress and considering fluid pressure yielded effective maximum and minimum horizontal stresses.

Fault properties provided the basis for later calculating normal stresses on the fault plane (Table 4). Vertical sealing coefficients were calculated for faults around Well A1 using the NSFP method (Fig. 5, Table 5).

The forecast showed all faults around Well A1 having varying degrees of sealing capacity. The same fault at different depths exhibited different sealing capacities. As a large fault controlling the reservoir, the sealing capacity of Fault 1 was considered good overall. Its sealing of Sublayer L1 was better than L2.

The third-order Faults 3 and 2, much smaller than 1, demonstrated better sealing capacity to L1 than L2. Both walls of L1 accumulated gas, with a large gas-water interface difference (Fig. 3).

Test data from Well A1 provided the basis for calculating gas reserves of Sublayers L2 and L1 in B1 offshore fault block area (Table 6). Gas reserves in Sublayer L1 were 1.66 108 cu m and gas reserves in L2 insufficient for commercial development. Bad sealing around sublayer L2 allowed gas to escape along the faults or through the faults. The sealing capacity of Fault 3 implied gas probably would leak, which would cause Sublayer L1 reserves to vary near Fault 3, demanding a corresponding production strategy.

Acknowledgments

The author is thankful for financial support from the National Major Basic Research Development Program of China (2014CB239205), and the National Science and Technology Major Project of China (20011 ZX 05030-005-003).

References

1. Ou, C.H., Chen, W., and Ma, Z.G., "Quantitative identification and analysis of subseismic extensional structure system: technique schemes and processes," Journal of Geophysics and Engineering, Vol. 12, No. 3, June 2015, pp. 502-514.

2. Berg R.R., and Avery A.H., "Sealing properties of tertiary growth faults, Texas Gulf Coast," American Association of Petroleum Geologists Bulletin (AAPG Bull.), Vol. 79, No. 3, March 1995, pp. 375-392.

3. Prestholm E. and Walderhaug O., "Synsedimentary Faulting in a Mesozoic Deltaic Sequence, Svalbard, Arctic Norway: Fault Geometries, Faulting Mechanisms, and Sealing Properties." AAPG Bull., Vol. 84, No. 4, April 2000, pp. 505-522.

4. Knipe R.J., "Juxtaposition and seal diagrams to help analyze fault seals in hydrocarbon reservoirs." AAPG Bull., Vol. 81, No. 2, April 2000, pp. 187-195.

5. Zhang L., Luo X., Liao Q., Yang W., Vasseur G., Yu C., Su J. Yuan S., Xiao D., and Wang Z., "Quantitative evaluation of synsedimentary fault opening and sealing properties using hydrocarbon connection probability assessment," AAPG Bull., Vol. 94, No. 9, September 2010, pp. 1379-1399.

6. Jones R.M., Dewhurst D.N., Hillis R.R., and Mildren S.D., "Geomechanical fault characterization: Impact on quantitative fault seal risking," Rock Mechanics Conference, Dallas, Oct. 20-23, 2002.

7. Aydinoglu G., Bhat M., and Ertekin T., "Characterization of Partially Sealing Faults from Pressure Transient Data: An Artificial Neural Network Approach," Society of Petroleum Engineers Eastern Regional Meeting, Lexington, Ky., Oct. 23-25, 2002.

8. Davison J.M., Van den Bogert P., Schutjens P., Ita J., Fokker P., "Geomechanical Technology for Seal Integrity Analysis: The Three-Step Approach," International Petroleum Technology Conference, Beijing, Mar. 26-28, 2013.

The author

Ou Chenghua ([email protected]) is an associate professor, reservoir description, Southwest Petroleum University, Chengdu, China. His focus areas include tight-reservoir description theory and technology, complex reservoir description, and residual-oil distribution. He holds a BS in oil and gas geology, an MA in coal, oil, and gas exploration, and a PhD in petroleum engineering, all from Southwest Petroleum University.