Analytical model predicts chemical EOR performance

Mohamed El-Tayeb

University of Wyoming

Laramie, Wyo.

Mostafa Kortam

Belayim Petroleum Co.

Cairo

Mahmoud Abu El Ela

Cairo University

Giza, Egypt

Ahmed El-Banbi

American University in Cairo

Cairo

Mohamed Helmy Sayyouh

Cairo University

Giza, Egypt

Polymer flooding is recommended for hydrocarbon reservoirs with high heterogeneity or a high water-oil mobility ratio since the addition of polymer to the injected water increases viscosity, plugs high‐permeability zones, and reduces the water’s mobility.1-5 Limiting water mobility reduces water fingering, increases areal and vertical sweep efficiency, and improves overall recovery efficiency. Besides improving volumetric efficiency, polymers could be used as a mobility control to complement other chemical EOR processes such as surfactant-polymer flooding and alkaline-surfactant-polymer flooding.4-6

Polymers are very sensitive to reservoir conditions such as temperature and salinity.7-12 Polymers also are subject to adsorption by rock, mechanical breakage, and shear degradation. Many laboratory tests therefore should be conducted before field application to select the right type of polymer and properly design its use. Typical successful incremental oil recovery from polymer flooding is 5-10%.2-9

Several analytical models have been developed to predict performance of chemical enhanced oil recovery (EOR) processes.13-19 Their common characteristics include:

- Ignorance of chemical dispersion.

- Negligence of fluid and rock compressibility.

- Irreversibility and instantaneousness of chemical adsorption.

- Assumption of isothermal flood.

- No consideration for areal heterogeneity (a single value of permeability for each layer).

Such characteristics limit application of these models and give incomplete results for economic analysis of chemical EOR processes.

This article takes into consideration the effect of reservoir heterogeneity and the physical and chemical properties of chemical fluids such as adsorption, permeability reduction, and non-Newtonian effects for different injection patterns. The developed model also is useable for either waterflooding or chemical flooding (polymer or surfactant-polymer). Options allow performance calculations to consider either continuous or slug injection and deal with either constant or variable injectivity to predict the performance of the designed chemical EOR process.

Analytical model

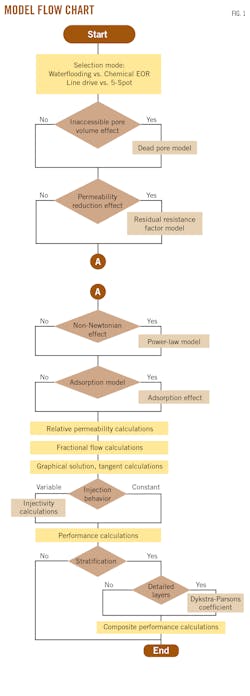

Fig. 1 presents the main flow chart of the developed model. The program can deal with either line drive or 5-spot patterns. In the case of a 5-spot pattern, injectivity and performance calculations are performed according to the Craig model.20 Otherwise, calculations are performed according to frontal advance theory.

The model uses fractional flow theory and the areal and vertical sweep models. Continuity equations for water and chemical species are also considered.21 These equations are solved analytically by using characteristics to obtain displacement efficiency.22 The stream tube approach is also utilized for combining displacement efficiency with areal sweep efficiency.22-23

This approach divides the reservoir into one-, four-, or eight-stream tubes, connecting the injector to the producer. One-dimensional linear displacement, therefore, is calculated along each stream tube by applying fractional flow theory in the given tube. To obtain the 3D model’s production, results from all stream tubes and layers are combined. Areal heterogeneity also is modeled using the stream tubes concept.22-23 Every cell can have its own permeability during flood front tracking. Previous models assumed a single permeability value for each layer.

Polymer solutions may be subject to shear degradation during the flood. In the developed model, the shear rate around the wellbore is assumed constant throughout the flood life. Polymer viscosity, therefore, is a function only in polymer concentration. The effect of non-Newtonian polymer rheology is accounted for in calculations of injection rate. Modeling behavior of non-Newtonian rheology uses the modified Blake-Kozeny model.24 The proposed treatment of other chemical features such as adsorption by rock, permeability reduction, and inaccessible pore volumes are considered within the analytical solution of the frontal advance theory to chemical EOR.21

Programming the model’s calculation procedures used several subroutines. Under a specific condition and type of injection scenario, the model can predict reservoir performance.

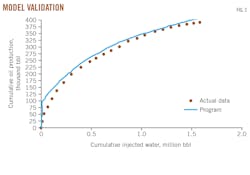

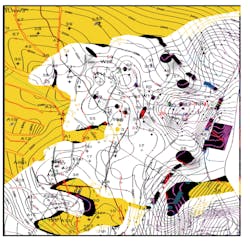

Validation of the model and its subroutines incorporated data from several case studies and field applications with different operating conditions. Fig. 2 presents results for one of the validation cases, using actual data from Brelum field. The field involves eight producing wells and 12 injection wells, settled in a staggered-line drive pattern. Fig. 2 shows good matching between actual reservoir performance and the developed model’s results. The model predictions are almost consistent with the field performance and measurements, deviating by about 5%.

Belayim pilot

Belayim Land polymer pilot project is in the Sinai region close to the Gulf of Suez and is operated by Belayim Petroleum Co. (Petrobel), a joint venture between Egyptian General Petroleum Corp. and Eni SPA. The developed program was run using Belayim Land pilot project data to predict polymer flooding performance.25

Belayim Land is a mature onshore field, having started production in 1955. At the time of the study, the pilot area had produced almost 1 million bbl of oil, with an actual recovery factor of 21%. Initial reservoir pressure was 3,500-4,000 psi, with a bubble-point pressure of nearly 1,000 psi.

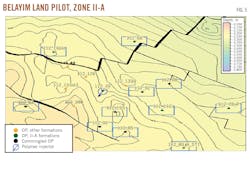

Belayim Land is a multilayer field with 12 separated reservoirs in the Miocene sequences Rudeis, Kareem, Belayim, South Gharib, and Zeit formations. Zone II-A (Fig. 3) was selected for polymer flooding.

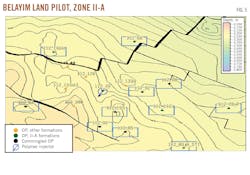

Fig. 4 shows the structural map of Zone II-A. This zone involves eleven production wells, marked with red dots and three peripheral injection wells, marked with blue dots. Water injection was started in 2001. The producers are placed high on the upper structure.

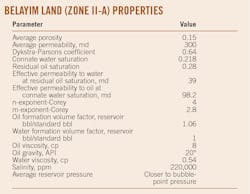

The accompanying table presents the reservoir rock and fluid properties of Belayim Land pilot project. Oil viscosity is extremely high compared with water viscosity. The mobility ratio is around 6, which is relatively high and unfavorable. Peripheral water injection has not added a significant amount of oil production, the recovery factor being 21% versus an expected 35%. A promising chemical EOR process was thought likely to maximize sweep efficiency by improving the mobility ratio and reducing residual oil saturation.

Polymer flooding was selected among the chemical EOR processes after screening. During the second stage (lab analysis), polymer flooding with a concentration of 1,500 ppm was designed to reach a viscosity of 6-8 cp and achieve a favorable mobility ratio of 0.5.

Simulation considered two scenarios, either using one of the peripheral wells (Well 112-57) as the injector for polymer flooding or recompleting another well in the pattern system to serve as the injection site. The first scenario was rejected after conducting several simulations of different strategies. Polymer flooding via Well 112-57 did not add any incremental recovery relative to water flooding due to the distance between the injector and the producers. The area affected by the polymer flooding seemed to be limited to the near-wellbore even after years of injection.

The second scenario, recompleting another well as injector in the pattern system, was selected on this basis. After conducting simulations to identify the optimum location of the injector, Well 112-79 was selected as the pilot (Fig. 5). The four producing wells were 112-140H, 112-68, 112-112, and 112-78.

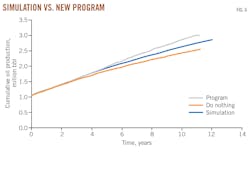

Fig. 6 shows the results of the simulation run for Well 112-79 as an injector, compared with predicted performance for about 12 years. The comparison displays a good and reasonable match between the results obtained from the simulation and the developed model, with an average deviation of 12%. This deviation might be related to the assumptions of having both a perfectly inverted 5-spot pattern and a single value of polymer concentration, as the developed model could neither replicate an irregular pattern nor a degraded slug.

The obtained match, however, confirms the capability and reliability of the developed model to predict the performance of actual field projects with reasonable accuracy.

Well 112-79 has commenced polymer injection. It has experienced sand production problems during shut-in periods, however, resulting from aggressive reperforation jobs. Such jobs are considered the primary cause of weakening the rock matrix of depleted reservoirs and are responsible for both sand production and fines migration. A corrective action to switch polymer injection to another well is being considered.

References

- Kessel, D.G.,“Chemical flooding-Status Report,” Journal of Petroelum Science and Engineering, Vol. 2, Nos. 2-3, April 1989, pp. 81–101.

- Abu El Ela, M., Sayyouh, H., and El Tayeb, S., “An Integrated Approach for the Application of the Enhanced Oil Recovery Projects,” Journal of Petroleum Science Research (JPSR), Science and Engineering Publishing Co., Vol. 3, No. 4, July 21, 2014.

- El-Abbas, A., El-Salaly, M., Sayyouh, M.H., El-Batanony, M., Darwich, T. and Desouky, S. “Feasibility of Oil Recovery by Chemical Flooding Through Horizontal Wells,” SPE International Conference on Horizontal Well Tech, Calgary, Nov. 1-4, 1998.

- Lake, L.W., Johns, R.T., Rossen, W.R. and Pope, G.A., “Fundamentals of Enhanced Oil Recovery,” Society of Petroleum Engineers, Richardson, Tex, 2014.

- Green D.W. and Willhite G.P., “Enhanced Oil Recovery,” Society of Petroleum Engineers, Richardson, Tex., 1998.

- Sayyouh, M.H., Al-Blehed, M.S. and Attia, A.M., “The effect of alkaline and polymer additives on phase behavior of surfactant-oil-brine system at high salinity conditions,” Revue Institute Francis du Petrol, Vol. 48, No. 4, July-August 1993, pp 359-369.

- Sheng, J.J., “Modern Chemical Enhanced Oil Recovery Theory and Practice,” Gulf Professional Publishing, Elsevier Inc., Burlington, Mass., 2011.

- Littmann, W., “Polymer Flooding,” Developments in Petroleum Science, Vol. 24, Elsevier Science Publishing Company Inc., NY, 1988.

- Taber, J.J. and Martin, F.D., 1983, “Technical Screening Guides for the Enhanced Recovery of Oil,” SPE 58th Annual Technical Conference and Exhibition, San Francisco, Oct. 5-8, 1983.

- El-Batanony, M.H., Sayyouh, M.H., Mahgoub, I.S. and Abdel-Waly, A., “Screening guides for enhanced oil recovery methods under Egyptian reservoir conditions,” Journal of Egyptian Society of Engineers, Vol. 26, No. 1, 1987, pp. 60-66.

- Sayyouh, M.H., Dokla, M.E. and Totonji, A., “Effect of salinity and temperature on polymer flooding,” 33rd Annual Technical Meeting of Petroleum Society of CIM, Calgary, June 1-3, 1982.

- Sayyouh, M.H., “A laboratory investigation of enhanced oil recovery methods by chemical solutions,” 33rd Annual Technical Meeting of the Petroleum Society of CIM, Calgary, June 1-3, 1982.

- Patton, J.T., Coats, K.H. and Colegrove, G.T., “Prediction of Polymer Flood Performance,” SPE Journal, Vol. 11, No. 1, March 1971, pp. 72-84.

- Dake, L.P., “Fundamentals of Reservoir Engineering,” Elsevier/North-Holland Inc., New York, 1979.

- Paul, W., Lake, L.W., Pope, G.A. and Young, G.B., “A Simplified Predictive Model for Micellar-Polymer Flooding,” Paper No. SPE 10733, regional meeting of Society of Petroleum Engineers, California USA, 24th -26th March, 1982.

- Jones, R.S., Pope, G.A., Ford, H.J. and Lake, L.W., “A Predictive Model for Water and Polymer Flooding,” SPE-DOE 4th Symposium on Enhanced Oil Recovery, Tulsa, April 15-18, 1984.

- Giordano, R.M., “Estimating Field-Scale Micellar/Polymer Performance,” SPE Annual Technical Conference, Dallas, Sept. 27-30, 1987.

- Mollaei, A. and Delshad, M., “General Isothermal Enhanced Oil Recovery and Waterflood Forecasting Model,” 86th SPE Annual Technical Conference and Exhibition, Denver, Oct. 30-Nov. 2, 2011.

- Darwich, T., Shindy, A., Sayyouh, M.H. and Osman, A., “Development of an Expert System for EOR method Selection,” 2nd Petroleum Computer Conference, Cairo, Egypt (April, 1995). Also, SPE 37709, Presented at MEOS 1997, Bahrain, (March.1997).

- Craig, F. F., Geffen, T. M., and Morse, R. A., “Oil Recovery Performance of Pattern Gas or Water Injection Operations from Model Tests,” Petroleum Transactions, AIME, 1955, Vol. 204, 7-15.

- Pope, G.A., “The Application of Fractional Flow Theory to Enhanced Oil Recovery”, SPE Journal, 1980, 20, No. 3: 191‐205.

- Higgins, R. V. and Leighton, A. J., “A Computer Method to Calculate Two-Phase Flow in Any Irregularly Bounded Porous Medium,” Journal of Petroleum Technology, Vol. 14, No. 6, June 1962, pp. 679–683.

- Higgins, R. V. and Leighton, A. J., “Computer Prediction of Water Drive of Oil and Gas Mixtures Through Irregularly Bounded Porous Media Three-Phase Flow,” Journal of Petroleum Technology, Vol. 14, No. 9, September 1962, pp. 1048-1054.

- Hirasaki, G.J. and Pope, G.A., “Analysis of Factors Influencing Mobility and Adsorption in the Flow of Polymer Solution Through Porous Media,” Society of Petroleum Engineers Journal, Vol. 14, No. 4, August 1974.

- El Tayeb, M., “Development of an Analytical Model to Predict the Performance of Chemical EOR Methods,” M.Sc. thesis, Faculty of Engineering, Cairo University, 2017.

The authors

Mohamed El-Tayeb ([email protected]) is a PhD student at University of Wyoming. Previously, he worked (from 2013 to 2017) as a teaching assistant at Cairo University, Egypt. He holds BS and MS degrees in petroleum engineering from Cairo University. He is an SPE member.

Mostafa Kortam ([email protected]) is a senior reservoir engineer working for Belayim Petroleum Co. (JV between Eni and Egyptian General Petroleum Corp.). He graduated from Cairo University with a BS in petroleum engineering (2008). He is an SPE member.

Mahmoud Abu El Ela ([email protected]) is a professor of petroleum engineering at Cairo University. He is also managing director for the Mining Studies & Research Center at the Faculty of Engineering, Cairo University. Since 1997, he has been a technical consultant in petroleum engineering for several national and international companies, including Khalda Petroleum Co. and Worley. Abu El Ela holds a BS and MS in petroleum engineering from Cairo University, and a PhD from Curtin University of Technology, Australia. Abu El Ela is an SPE member and is faculty advisor for the SPE Student Chapter at Cairo University.

Ahmed El-Banbi ([email protected]) is a professor of petroleum engineering and chair of the petroleum engineering department at the American University in Cairo. He previously worked for Cairo University. Prior to that, El-Banbi worked for Schlumberger, where he held a variety of technical and managerial positions in five countries. He holds BS and MS degrees from Cairo University, and MS and PhD degrees from Texas A&M University, all in petroleum engineering. El-Banbi is an SPE member and has been a member of numerous SPE committees.

Mohamed Helmy Sayyouh ([email protected]) is a professor of petroleum reservoir engineering at Cairo University. He was the Chairman of the Department of Mining, Petroleum and Metallurgical Engineering, Faculty of Engineering at Cairo University from 2005 to 2008. Since 1986 he had been a consultant engineer in the areas of petroleum reservoir engineering, enhanced oil recovery, reservoir simulation, and natural gas engineering. He was an active member in the Egyptian High Production Committee between 1995 and 2001. He obtained his BS (1970) and MS (1974) degrees in petroleum engineering from Cairo University and a PhD (1979) from Penn State University. Dr. Helmy is a member of SPE, AIME, Egyptian Society of Engineering Professions, and New York Academy of Science.