Denmark-based operator lets contract for first-of-a-kind electrofuels plant

Arcadia eFuels APS of Denmark has let a contract to Technip Energies to deliver front-end engineering and design (FEED) on the operator’s proposal to build what it says would be the first-ever plant to produce carbon-neutral electrofuels (eFuels)—including a sustainable aviation fuel (SAF)-equivalent—from renewable electricity, water, and biogenic carbon dioxide (CO2).

Technip Energies will engineer a plant that will produce about 55,000 tonnes/year (tpy) of eJet fuel (eKerosine), 25,000 tpy of eNaphtha, and an unidentified volume of eDiesel, all of which can respectively be blended up to 50% with conventional jet and road fuels to help the aviation and heavy transportation industries meet voluntary and regulatory carbon-reduction goals in line with the global energy transition, the service provider said.

In addition to the eFuels plant, Technip Energies said its scope of delivery includes engineering of an associated 250-Mw electrolyzer for production of green hydrogen at the complex, which will be built at the port of Vordingborg, Denmark, in the southern part of Zeeland, 100 km south of Copenhagen.

With pre-FEED and early works recently completed, the eFuels complex is scheduled for startup in 2026.

The FEED contract award follows Arcadia eFuels’ preliminary selection of Technip Energies Italy SPA to provide both FEED and engineering, procurement, and construction (EPC) services for the project. Arcadia eFuels also confirmed its January 2022 award of a joint contract to Topsoe AS and Sasol Ltd. for delivery of preliminary engineering on the proposed eFuels plant, which will be based on the service providers’ integrated G2L eFuels technology.

While Arcadia eFuels has yet to confirm taking positive final investment decision (FID) on the project that—as of November 2022—was due by yearend 2022, the operator said the proposed e-Fuels plant’s production of net-zero carbon aviation fuel would exceed Denmark’s total requirements for eFuels established under national mandates targeting carbon-neutral domestic air travel by 2030.

Given the project’s location at Vordinborg Port, the plant’s excess production of e-Fuels—which can be transported using existing liquid-fuels infrastructure—would be available for export to markets abroad, Arcadia eFuels said.

e-Fuels production

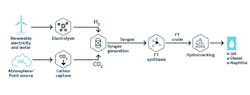

Arcadia eFuels said production at its proposed plant will involve the following:

- Electrolysis. Using renewable electricity to power an electrolysis process, water will be split into green hydrogen and oxygen.

- Captured CO2. CO2 will be sourced either from biogenic carbon via carbon capture technology at a designated source, from direct air capture, or a combination of the two.

- Electrified reverse-water gas shift. Hydrogen produced from the electrolysis process will react with captured CO2 to produce water and carbon monoxide, or syngas, as a feedstock to the Fischer Tropsch (FT) process.

- Low-temperature FT process. A catalytic chemical reaction will convert syngas into hydrocarbons.

- Hydroprocessing. Hydrocarbons produced in the FT process will be converted into eJet fuel, eDiesel, or a combination of both, along with smaller amounts of eNaphtha and eLPG.

Alternatively known as a Power-to-X (PtX, P2X) technology, the operator’s selected Topsoe-Sasol G2L process consists of the service providers’ following proprietary technologies:

- Topsoe’s SynCor reforming technology for converting methane-rich gas and oxygen to carbon monoxide and hydrogen, the two key syngas components required by the low-temperature Fischer-Tropsch (LTFT) synthesis process.

- Sasol’s LTFT synthesis process for catalytic conversion of carbon monoxide and hydrogen into long-chain molecules.

- Topsoe’s hydroprocessing technology, which breaks down, isomerizes, and saturates the long-chain molecules to produce designated end-products (e.g., jet fuel, diesel, naphtha).

- Topsoe’s hydrogen technology for production of low-carbon hydrogen to power associated hydroprocessing and syngas processes (see figure).

About the Author

Robert Brelsford

Downstream Editor

Robert Brelsford joined Oil & Gas Journal in October 2013 as downstream technology editor after 8 years as a crude oil price and news reporter on spot crude transactions at the US Gulf Coast, West Coast, Canadian, and Latin American markets. He holds a BA (2000) in English from Rice University and an MS (2003) in education and social policy from Northwestern University.